Preparation method of intermediate for polyurethane sponge

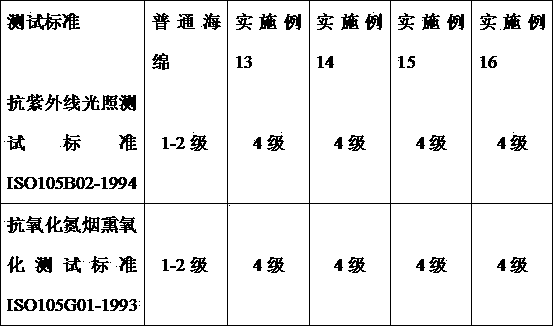

A technology for polyurethane sponges and intermediates, which is applied in the field of preparation of intermediates for polyurethane sponges, can solve the problems of unstable product quality, uneven sponge structure, labor and material consumption, etc., and achieves long storage validity period and reduced batch differences. , The effect of reducing production and processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1. Add 20 parts by weight of isophorone diisocyanate, 100 parts by weight of polyether polyol and 0.005 part by weight of the catalyst stannous octoate into the reactor and stir evenly. The temperature is 50°C and the reaction time is 10 hours to obtain Intermediate for stable polyurethane foam.

Embodiment 2

[0023] Example 2. Add 30 parts by weight of isophorone diisocyanate, 100 parts by weight of polyether polyol and 0.01 part by weight of organic bismuth catalyst into the reactor and stir evenly. The temperature is 90°C and the reaction time is 6 hours. Intermediate for stable polyurethane foam.

Embodiment 3

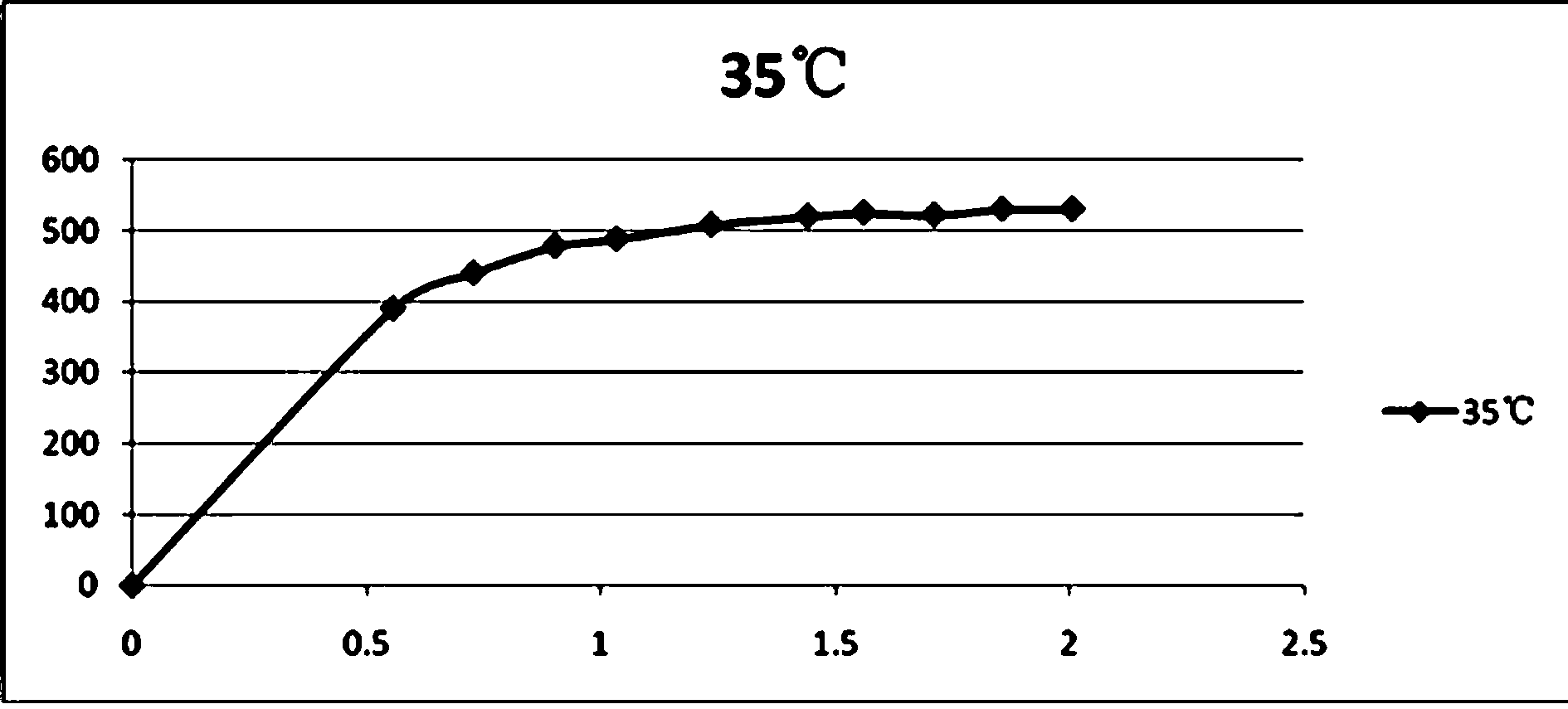

[0024] Example 3: Add 40 parts by weight of isophorone diisocyanate, 100 parts by weight of polyether polyol and 0.5 parts by weight of catalyst 1,4-diazabicyclo 2.2.2 octane into the reactor and stir evenly, and the temperature is 35°C, the reaction time is 48 hours, and a stable polyurethane sponge intermediate is prepared.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap