A frame type drainage well and its construction method

A construction method and technology for drainage wells, which are applied to drainage structures, waterway systems, water supply devices, etc., can solve problems such as inconvenient use and troublesome baffle installation, and achieve the effects of good integrity, convenient operation, and guaranteed safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The following describes in detail with reference to the accompanying drawings and embodiments.

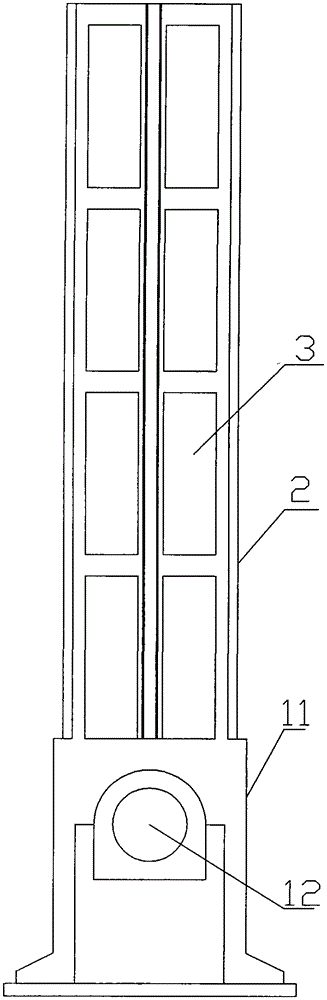

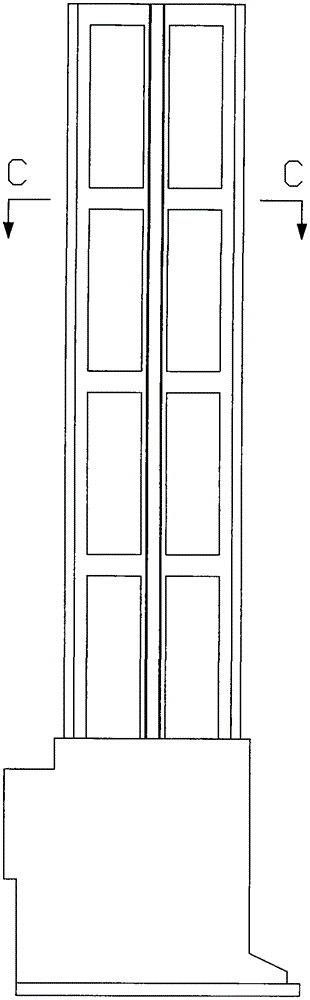

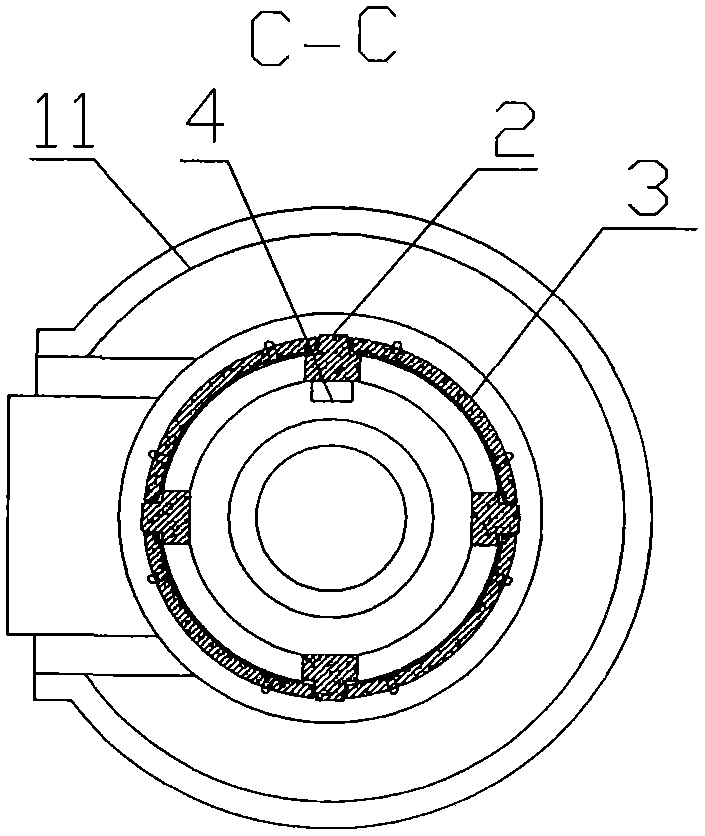

[0047] like Figure 4 to Figure 12 As shown, a frame-type drainage well includes a well seat 11, a derrick is arranged on the top of the well seat 11, the derrick includes a well column 2 and a ring beam 14, the well column 2 is provided with a pin shaft hole in the vertical direction, and the pin shaft hole is inserted with The pin shaft 8, a ring beam 14 is arranged between the adjacent well columns 2, the inner space surrounded by the well column 2 and the ring beam 14 is vertically stacked with an annular baffle 5, the annular baffle 5 is cylindrical, and the annular baffle The inner wall of 5 is provided with lifting lugs 13, the outer wall of the annular baffle 5 is matched with the inner wall of the well column 2 and the ring beam 14, each annular baffle 5 is supported by the pin shaft 8 of the same height, and the top of the well seat 11 is provided with a lifting lu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com