High-performance insulation profile

A high-performance, profile technology, applied in profile doors and windows, high-performance heat-insulating profiles, and curtain walls, can solve the problems of poor heat-insulation performance and connection strength of heat-insulating aluminum profiles, and achieve high overall heat insulation performance and high connection strength , Improve the effect of heat insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0017] Example 1:

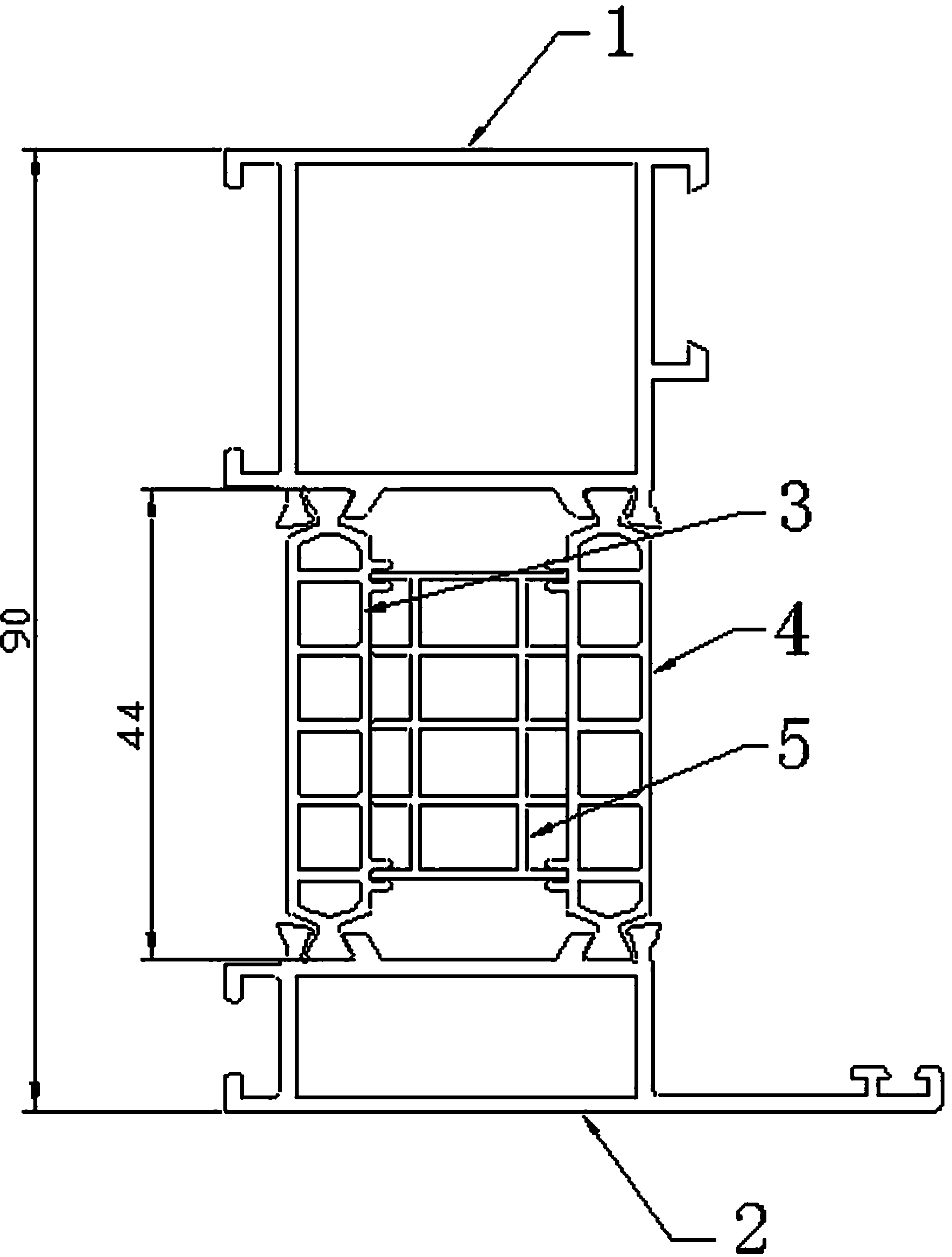

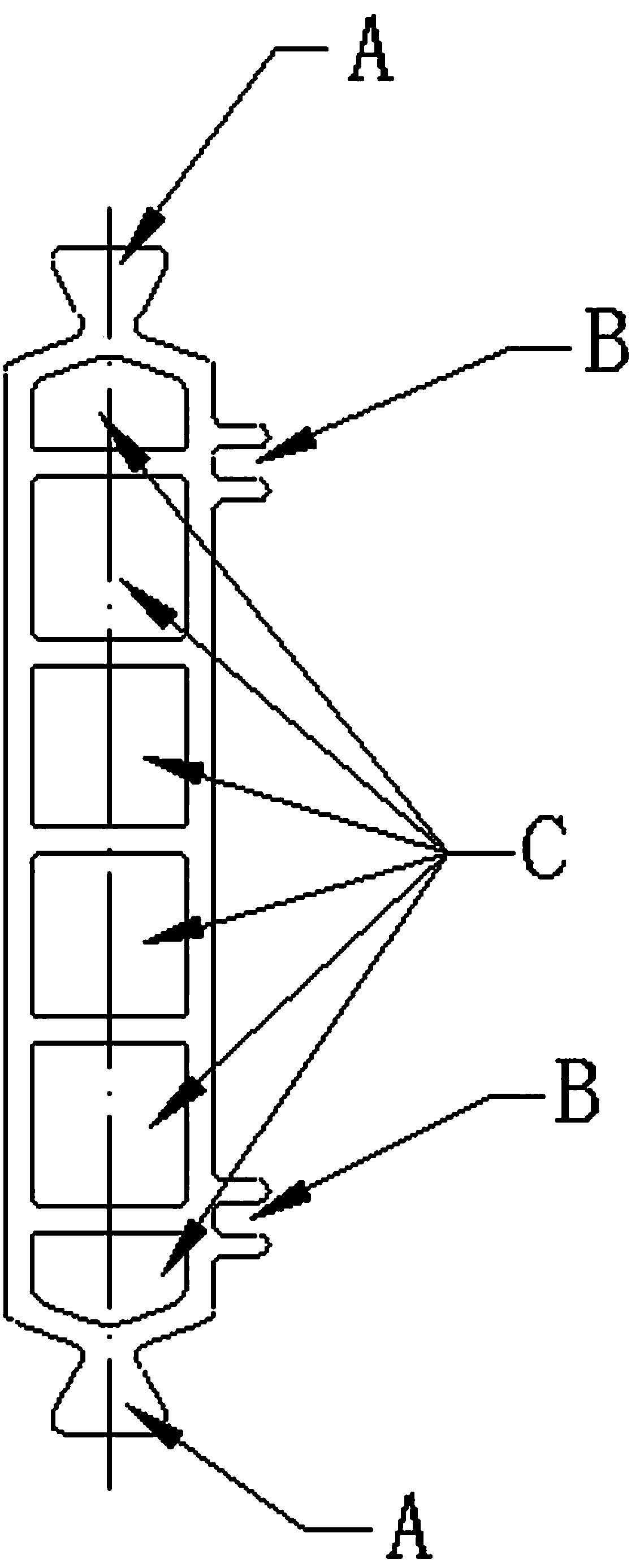

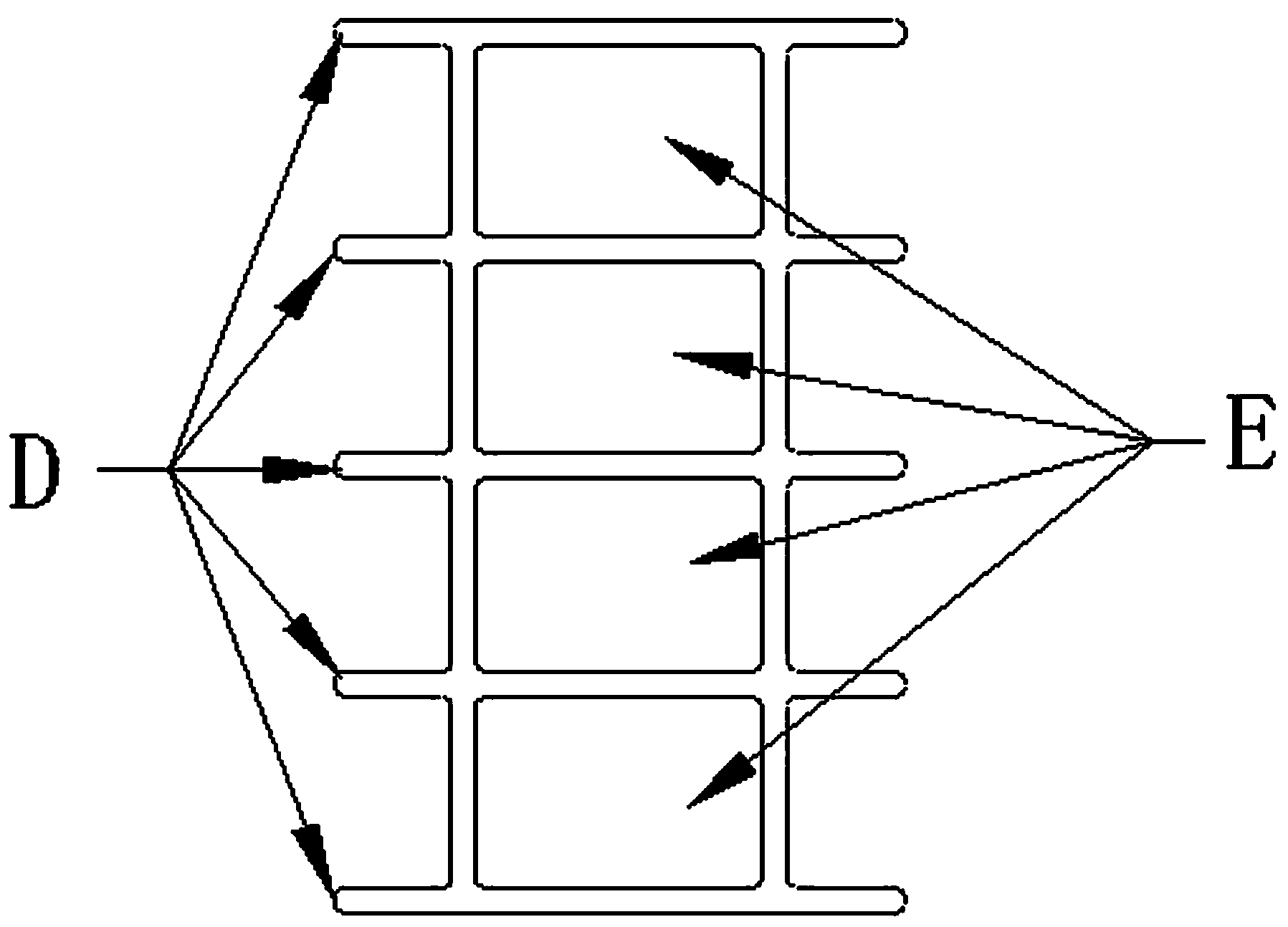

[0018] See figure 1 , figure 2 , image 3 The high-performance heat-insulating profile includes a first profile 1 and a second profile 2 placed in parallel, characterized in that the first profile 1 and the second profile 2 pass through at least two six or more cavities between opposite sides The ultra-wide heat-insulating connection nylon strips 3 and 4 with a width of 40mm or more are fixedly connected with the heat-insulating element. There are two ultra-wide heat-insulating connecting nylon strips 3 and 4, and the two ends of each ultra-wide heat-insulating connecting nylon strip are respectively fixed to one side of the first profile 1 and the second profile 2 through a slot; The heat insulation member is a PVC support strip 5 with at least 4 cavities. Both ends of the two ultra-wide heat-insulating connecting nylon strips 3, 4 are provided with chucks that engage with the grooves provided on the first profile 1 and the second profile 2, respectively; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap