Fuel injector and fuel injection device using same

A fuel injector and injection port technology, which is applied to fuel injection devices, charging systems, machines/engines, etc., can solve problems such as damage to the movable core stator core, and achieve the effect of reducing changes and limiting damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

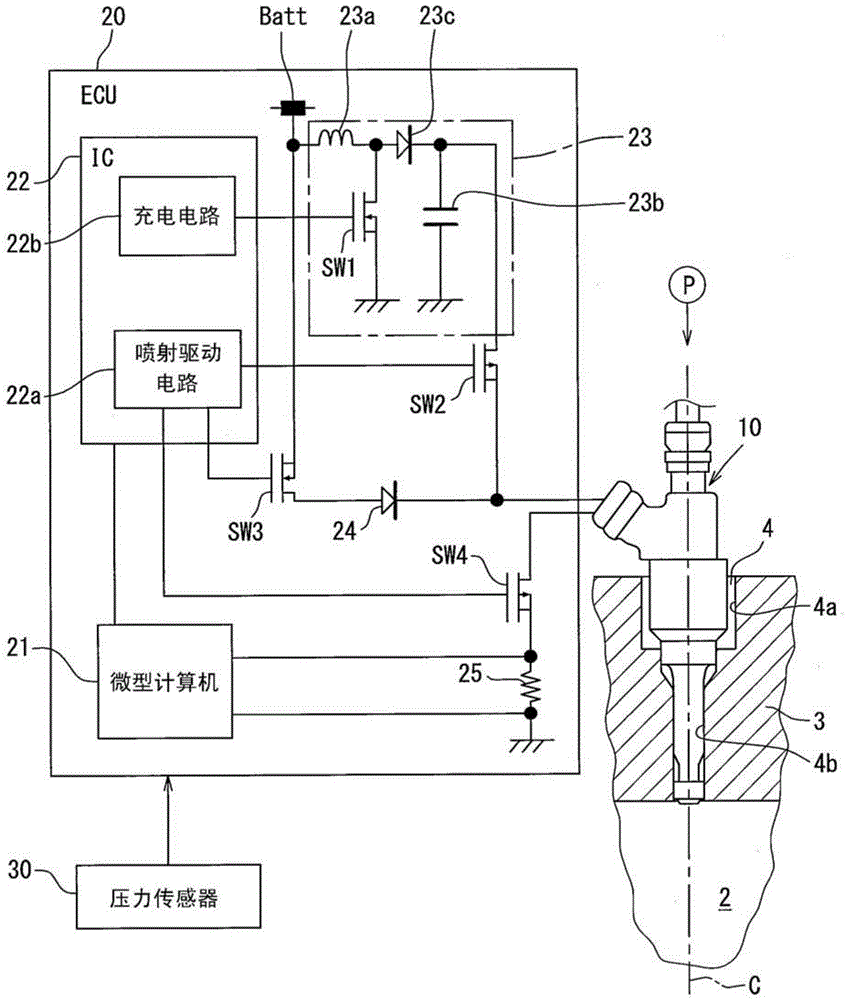

[0021] Such as figure 1 As shown in , a fuel injector 10 is mounted on an ignition type internal combustion engine and injects fuel directly into a combustion chamber 2 of the internal combustion engine. For example, the internal combustion engine may be a gasoline engine. Specifically, an attachment hole 4 for inserting a fuel injector 10 is axially provided in a cylinder head (cylinder head) 3 along an axis C of the cylinder. Fuel supplied to the fuel injector 10 is pumped by a fuel pump P driven by an internal combustion engine.

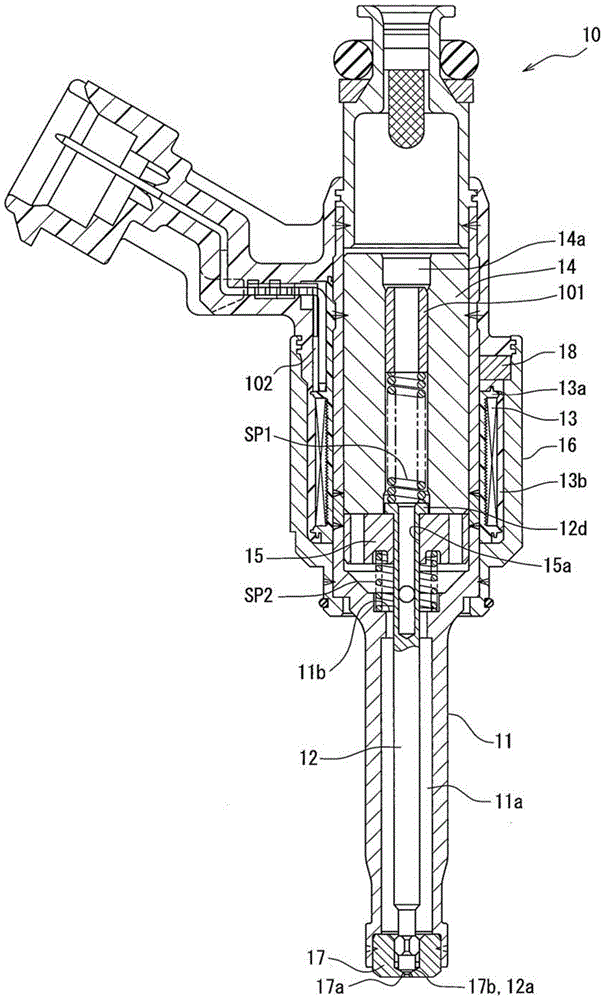

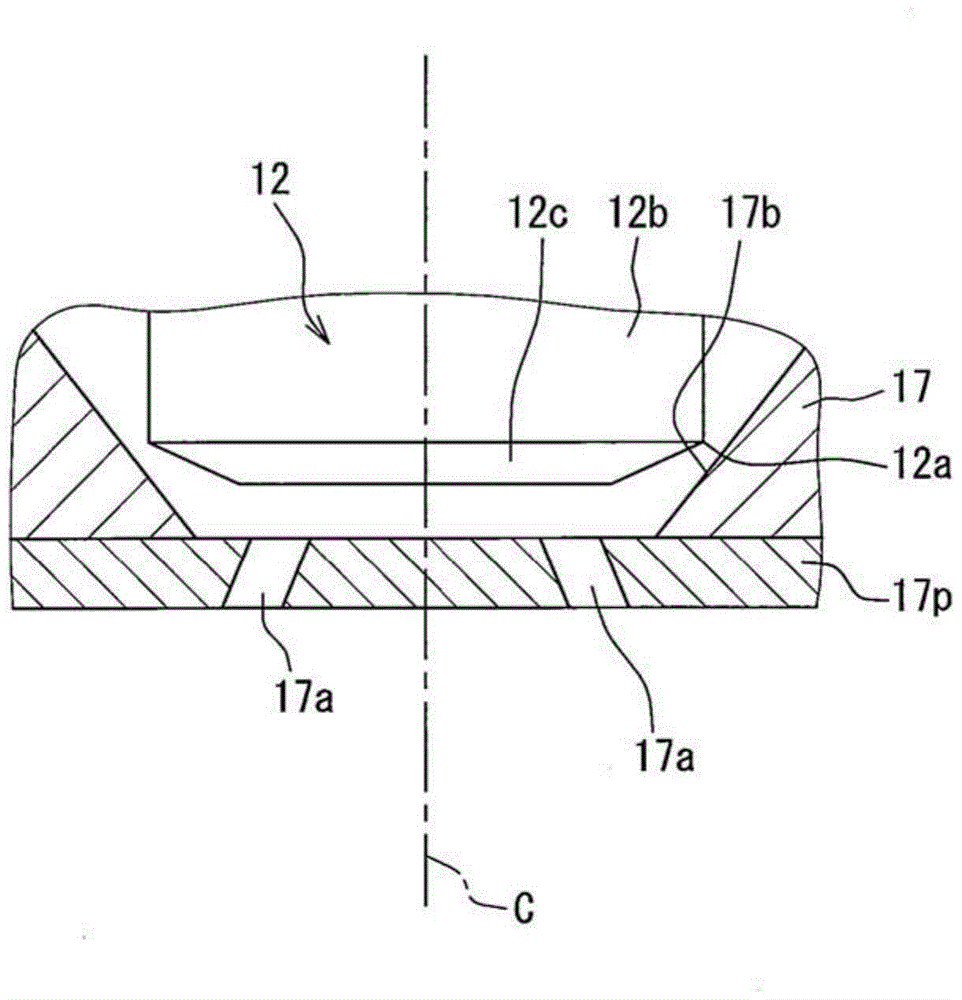

[0022] Such as figure 2 As shown in , the fuel injector 10 includes a body 11 , a valve body 12 , a first coil 13 , a stator core 14 , a movable core 15 and a housing 16 . The body 11 is made of a magnetic metal material and includes a fuel passage 11a. The body 11 forms a seated surface 17b and an injection port 17a. The valve body 12 abuts on the seating surface 17b or is separated from the seating surface 17b. Fuel is injected through th...

no. 2 example

[0093] According to the first embodiment, the boundary between the main body 12b and the end portion 12c functions as the seating surface 12a. According to the second embodiment, as Figure 8 As shown in , the end 12e is generally spherical and extends from the main body 12b toward the injection port 17a. Furthermore, that portion of the end portion 12e which abuts against the seating surface 17b functions as the seating surface 120a. In other words, the seating surface 120a replaces the seating surface 12a. Such as Figure 8 As shown in , the seating surface 120a has a curved portion. According to the first embodiment, the seating surface 12a has an inclined section.

[0094] The ratio of the fuel pressure valve closing force Ffo to the fuel pressure valve closing force Ffc is called a throttle ratio Tr.

[0095] Tr=Ffo / Ffc

[0096] Since the fuel pressure valve closing force Ffo decreases according to an increase in the throttle ratio Tr, it is possible to limit the gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com