Electrical contactor with flywheel drive and method for switching on and/or disconnecting the electrical contactor

A technology for electrical contacts and contactors, applied in relays, electrical switches, electrical components, etc., can solve problems such as destructive arc loads in the contact area, and achieve the effects of flywheel weight optimization, rebound tendency reduction, and simple cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The same reference numerals are used for identical or identically acting elements of the invention. The illustrated embodiments represent only examples of how the device according to the invention and the method according to the invention can be designed and do not represent definitive restrictions.

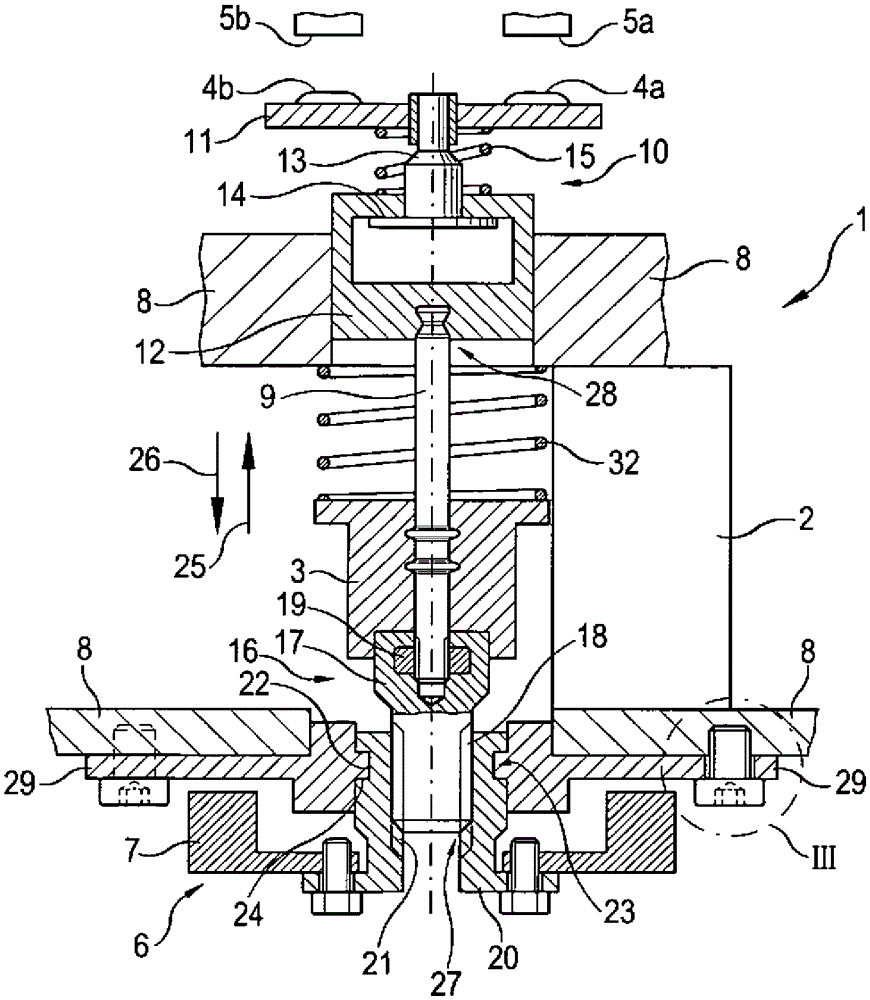

[0034] figure 1 and 2 Shown is an electrical contactor 1 according to the invention having a stator 2 and an armature 3 movable relative thereto, which is connected to at least one contact area 4a or 4b, preferably two contact areas 4a and 4b . These contact areas 4a and 4b can be connected to preferably fixed counter contact areas 5a and 5b respectively. Furthermore, a propulsion device 6 in the form of a flywheel 7 is connected to the armature 3 .

[0035]The stator 2 positioned laterally to the armature 3 is fixedly connected to the housing 8 of the electrical contactor 1 . Furthermore, the activation and supply of the stator 2 are not shown here, which can include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com