Method and equipment for preparing micronized medicines by using microreactor

A microreactor and reactor technology, applied in the direction of granulating raw materials, chemical instruments and methods, chemical/physical/physicochemical reactors, etc., can solve severe collisions, unfavorable drug generation or crystallization, and liquid reaction. Flow or not fully reacted into the sample pipeline and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

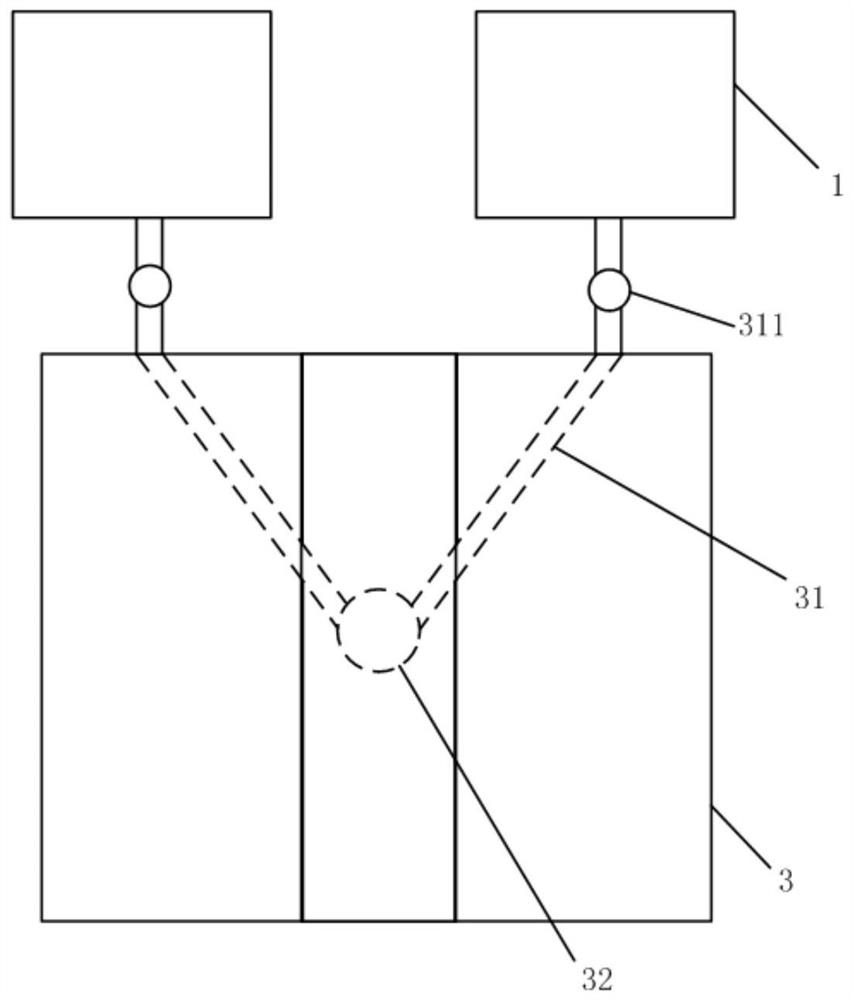

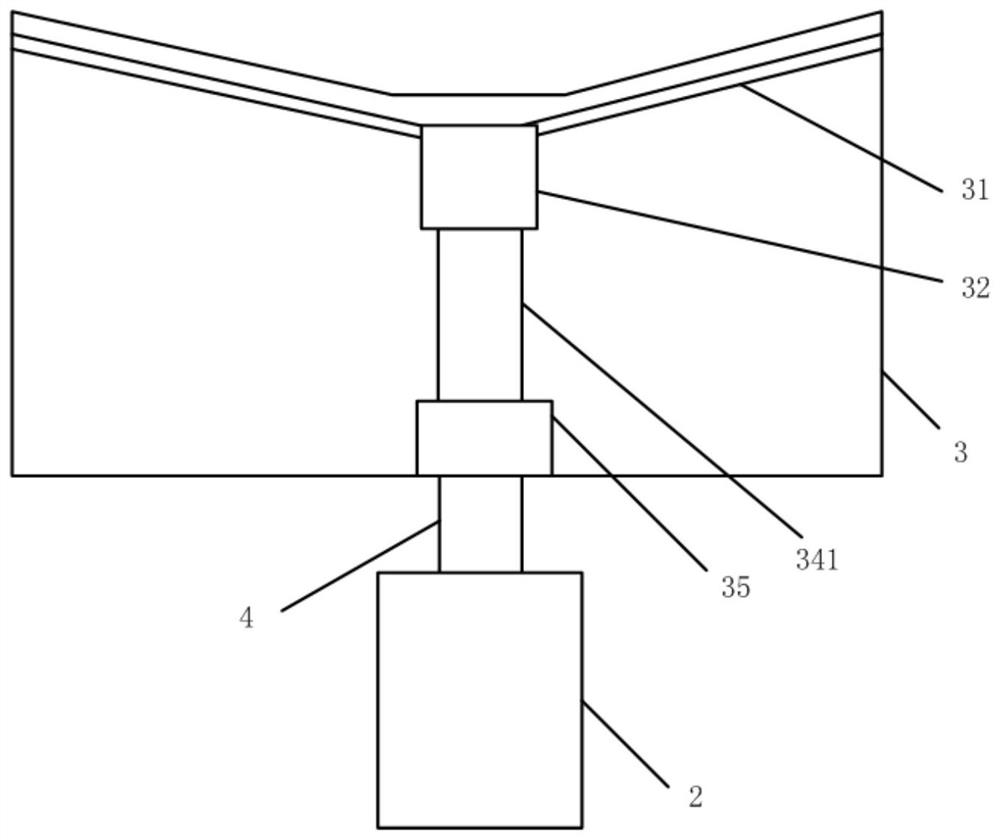

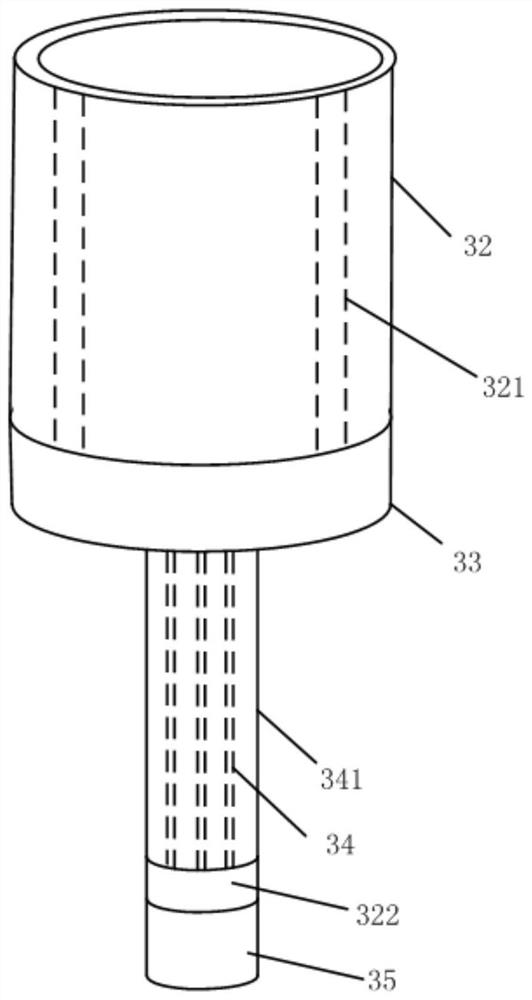

[0034] This embodiment provides a microreactor for producing micronized medicine, see Figure 1-3 , including a reactor main body, a plurality of raw material boxes 1, and a collection box 2. Different raw material boxes 1 are used to hold different liquids, such as reaction raw materials, reaction reagents, solvents, catalysts, etc. for producing medicines. The main body of the reactor is used for Micro-reaction, drying and other operations are carried out. The upper end of the main body of the reactor is respectively connected with a plurality of raw material boxes 1, and the lower end is connected with the collection box 2. The collection box 2 is used to collect the prepared micronized medicine. The main body of the reactor, a plurality of raw material boxes 1 and collection boxes 2 are installed on the brackets respectively.

[0035] The structure of the reactor main body is as follows, including a protective shell 3 , a sample injection tube 31 , a flow guide table 32 , ...

Embodiment 2

[0040] A kind of method utilizing microreactor to prepare micronized medicine, comprises the following steps:

[0041] First, select appropriate raw materials according to the structure and characteristics of the target drug, and prepare a raw material solution and a reaction reagent solution. Each raw material box 1 contains a liquid, and the pump 311 is in a closed state at this time;

[0042] Second, open all pumps 311 and control different liquids to flow at different flow rates. For example, when the raw material solution for preparing medicine is one and the reaction reagent solution is also one, the ratio of the flow rate of the control raw material solution to the reaction reagent solution is 1:80-100; when the pump 311 is turned on, the drug is gradually generated in the reaction chamber 33, and then flows out in a trickle through the drainage tube 34. Since this process has a delay in the reaction time, the opening time of the dryer 35 can be at the same time as the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com