A Numerical Evaluation Method for Porosity of Composite Materials Based on Ultrasonic Testing

A composite material, ultrasonic testing technology, applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, etc., can solve the problems of long cycle, easy to cause misjudgment, and failed to be popularized and applied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

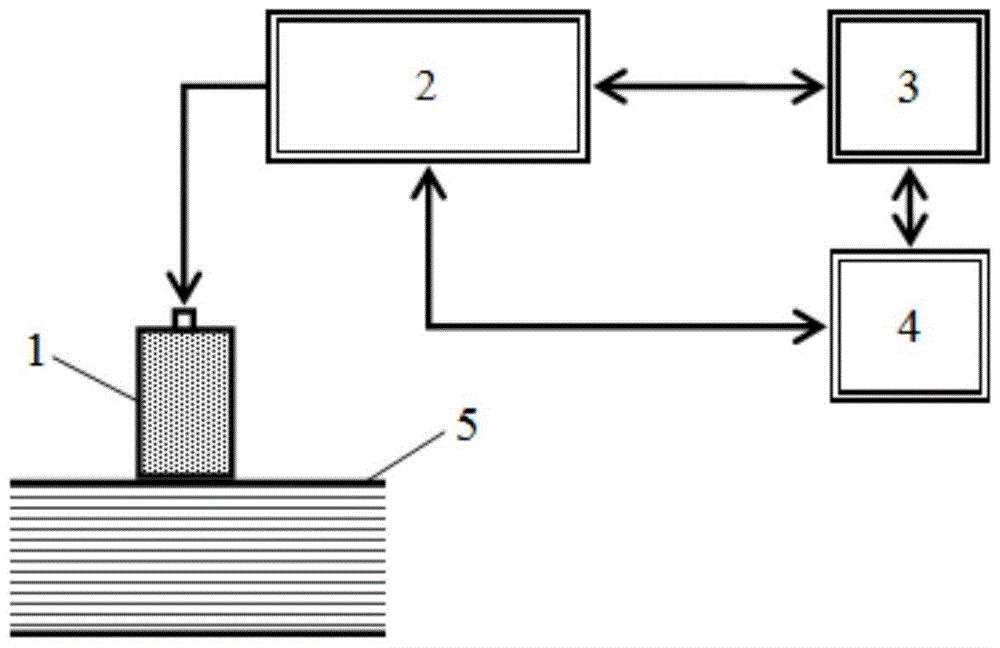

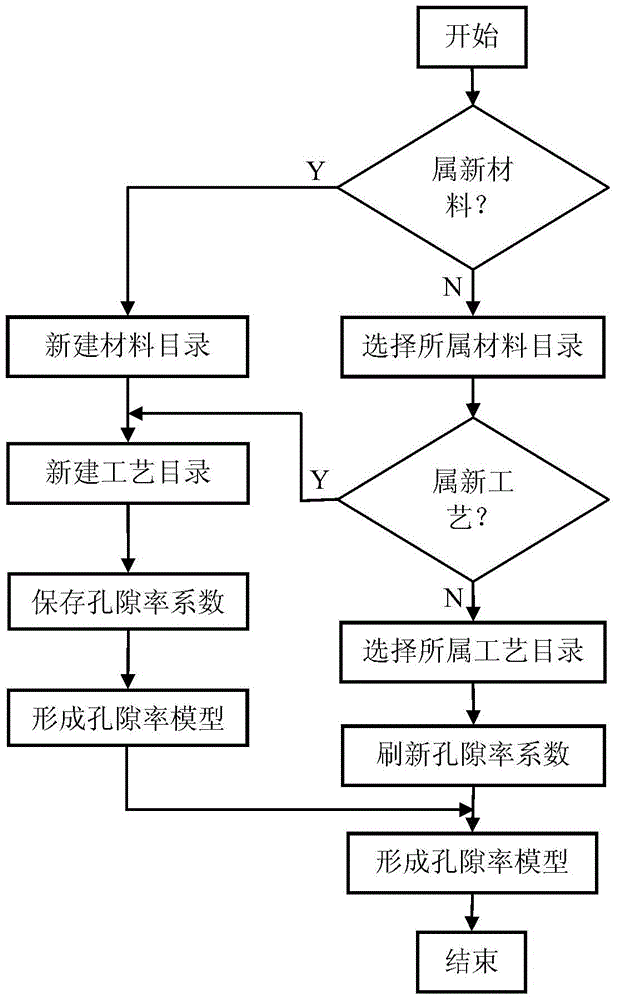

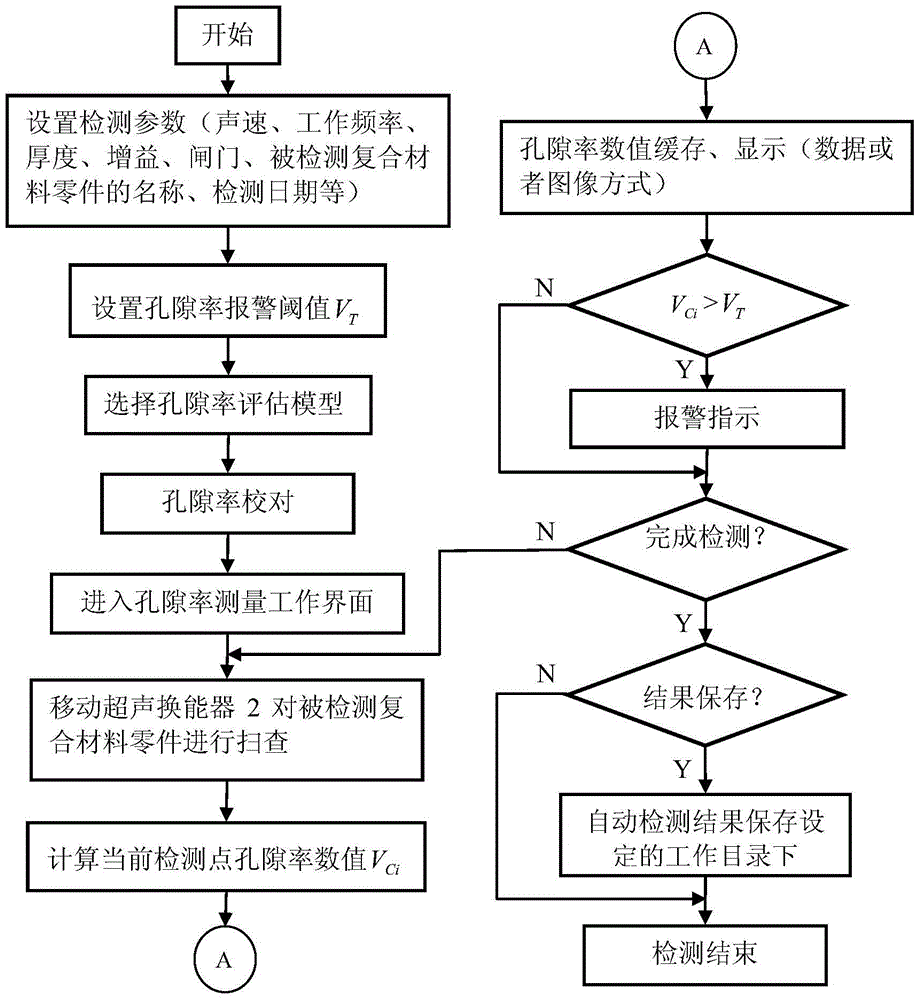

[0033] The basic composition of the method of the present invention includes: ultrasonic transducer 1, ultrasonic detection unit 2, porosity evaluation modeling 3, porosity construction database 4, such as figure 1 As shown, the composite material part 5 is scanned by the ultrasonic transducer 1. During the scanning process, the ultrasonic inspection unit 2 performs real-time porosity numerical evaluation, alarm indication, result storage and evaluation of the composite material part 5 according to the selected porosity evaluation model. Numerical analysis of porosity, etc. Ultrasonic transducer 1 adopts an ultrasonic transducer suitable for surface contact coupling or non-contact coupling of the tested composite material parts to realize the transmission and reception of ultrasonic detection signals. The FJ series of high-resolution ultrasonic transducers produced by AVIC Composite Materials Co., Ltd. can be used The ultrasonic testing unit 2 is composed of an ultrasonic testi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com