Composite material porosity value evaluation method based on ultrasonic detection

A composite material and ultrasonic testing technology, which is applied in the direction of using sound wave/ultrasonic wave/infrasonic wave to analyze solids, etc., can solve problems such as long cycle time, environmental pollution, and easy misjudgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

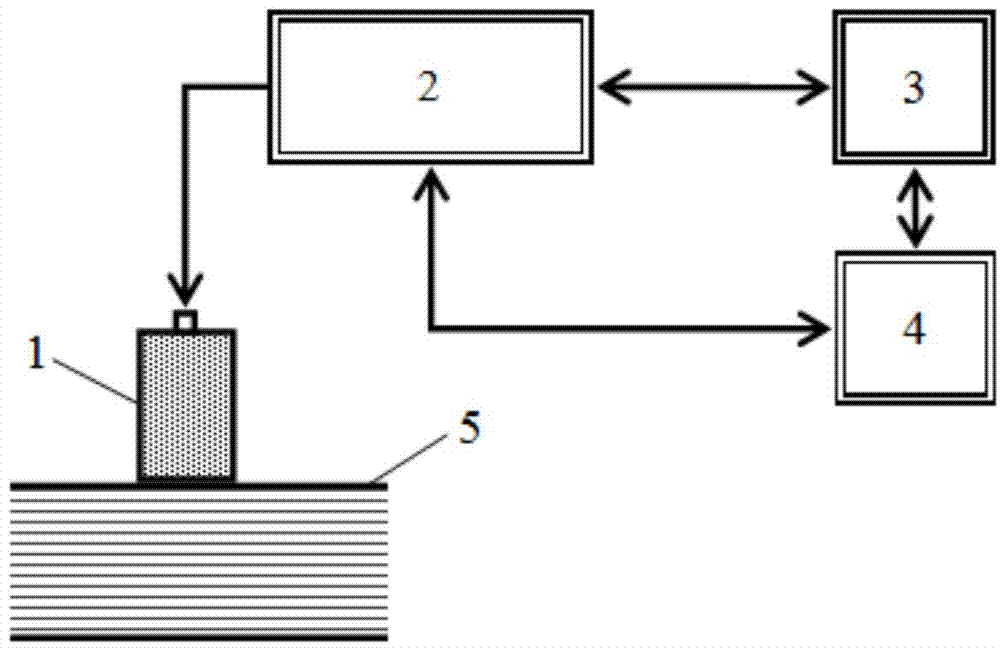

[0033] The basic composition of the method of the present invention includes: ultrasonic transducer 1, ultrasonic detection unit 2, porosity evaluation modeling 3, porosity library building 4, such as figure 1 As shown, the composite material part 5 is scanned by the ultrasonic transducer 1. During the scanning process, the ultrasonic detection unit 2 performs real-time porosity evaluation, alarm indication, result storage and Numerical analysis of porosity, etc. Ultrasonic transducer 1 adopts a contact coupling or non-contact coupling ultrasonic transducer suitable for the surface of the composite material part to be tested to realize the transmission and reception of ultrasonic detection signals. The FJ series of high-resolution ultrasonic transducers produced by AVIC Composite Materials Co., Ltd. can be selected. Ultrasonic testing unit 2 is composed of ultrasonic testing instruments with functions of detecting signal digitization, detection signal display, detection parame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com