Knob test device and knob test equipment

A technology of test device and rotary drive device, which is applied in the direction of measuring device, circuit breaker test, mechanical component test, etc., can solve the problems of complicated test process, cycle and cost increase, etc., so as to reduce test cost and simplify test procedure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

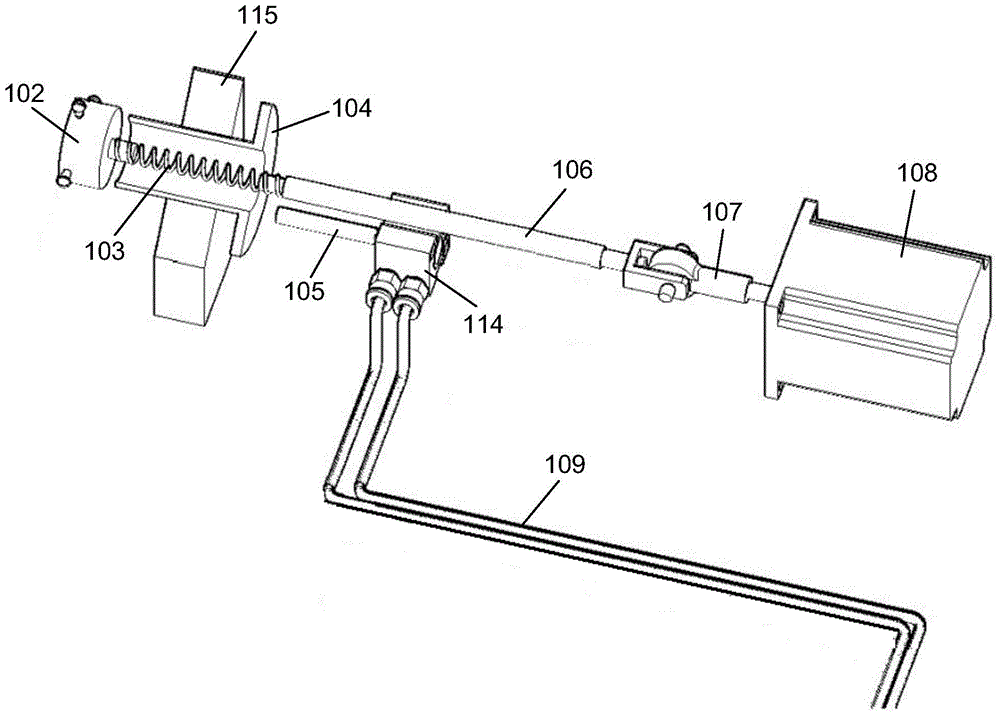

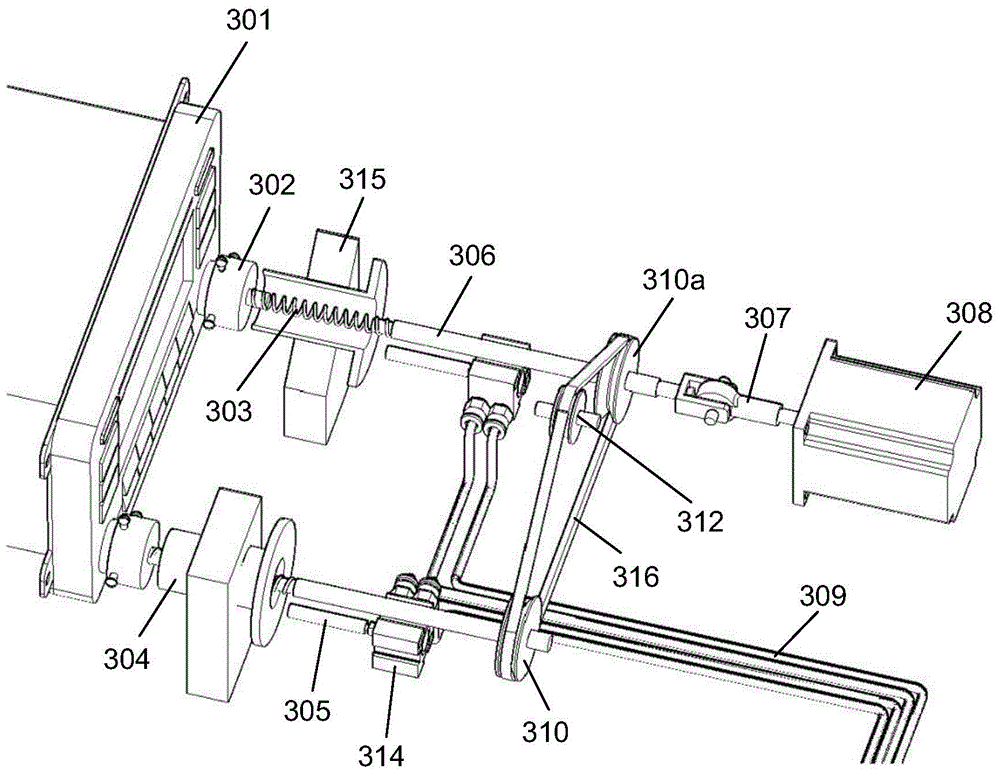

[0023] refer to figure 1 as shown, figure 1 A structural diagram of a knob testing device according to an embodiment of the present invention is disclosed. The knob test device includes: a fixture, an elastic shaft, a linear testing mechanism and a rotating testing mechanism.

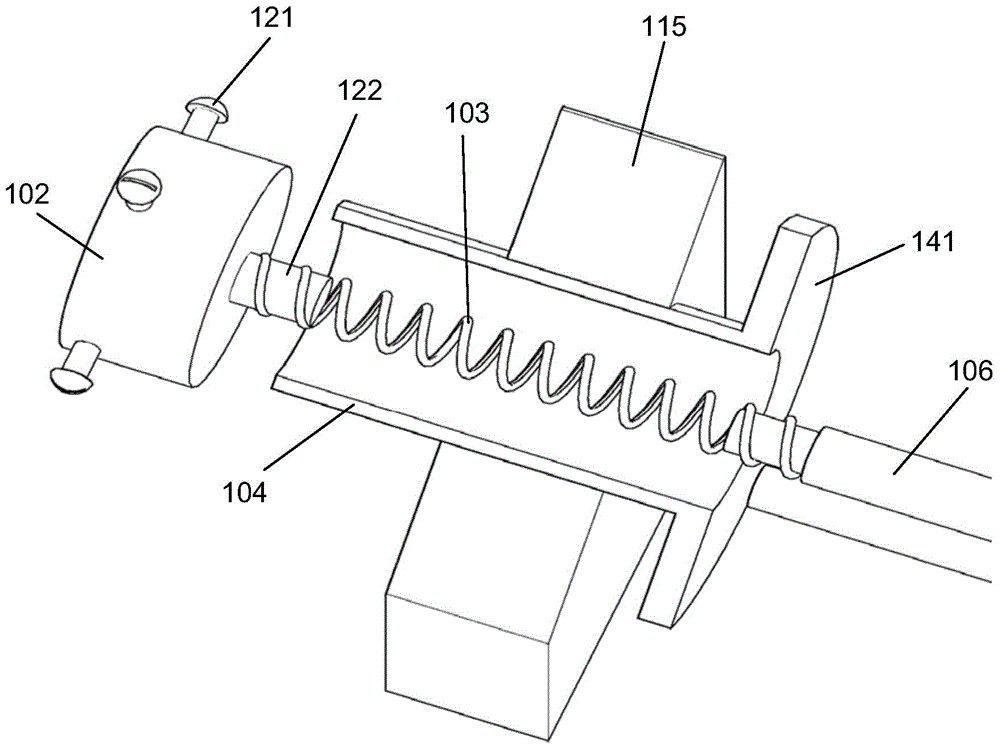

[0024] The clamp 102 is fixed on the knob. further reference figure 2 As shown, the clamp 102 is cylindrical, the first end is open, and the second end is closed. The knob is put into the clamp by the first end of the clamp. The side wall of the clamp 102 has a fixing bolt 121. The fixing bolt 121 is tightened to tighten the clamp 102. fixed on the knob. In the illustrated embodiment, there are four fixing bolts 121 on the side wall of the clamp 102 , and the four fixing bolts are tightened inwardly to clamp the knob, so that the knob and the clamp 102 are firmly connected. The second end of the clamp has a protrusion 122 connected to the first end of the elastic shaft.

[0025] The elastic shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com