A method for laying submarine pipeline leak detection optical cable

A submarine pipeline and leak detection technology, applied in the direction of optical fiber/cable installation, etc., can solve problems such as poor operability, difficult construction, and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

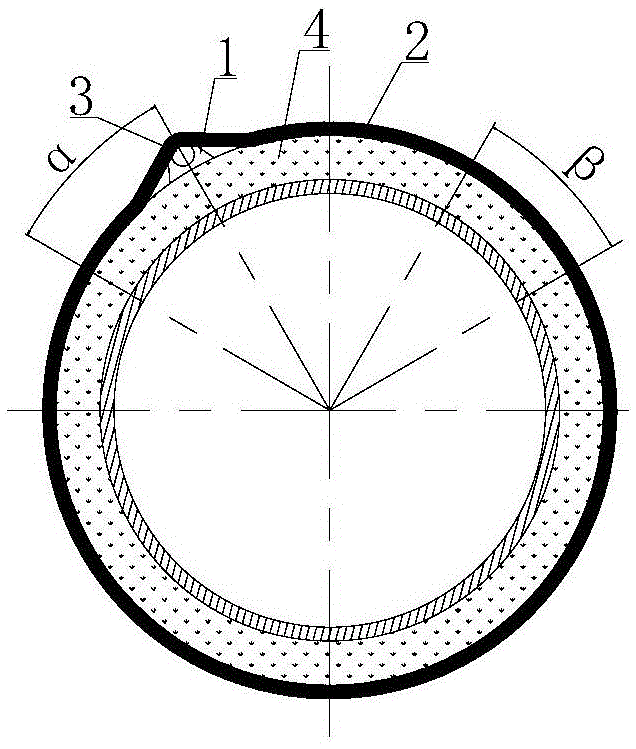

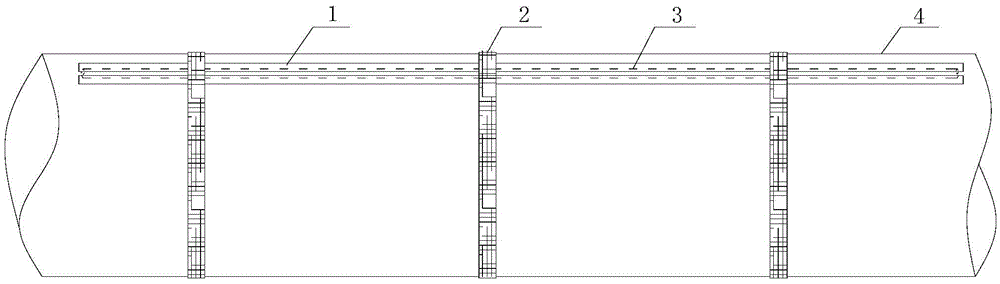

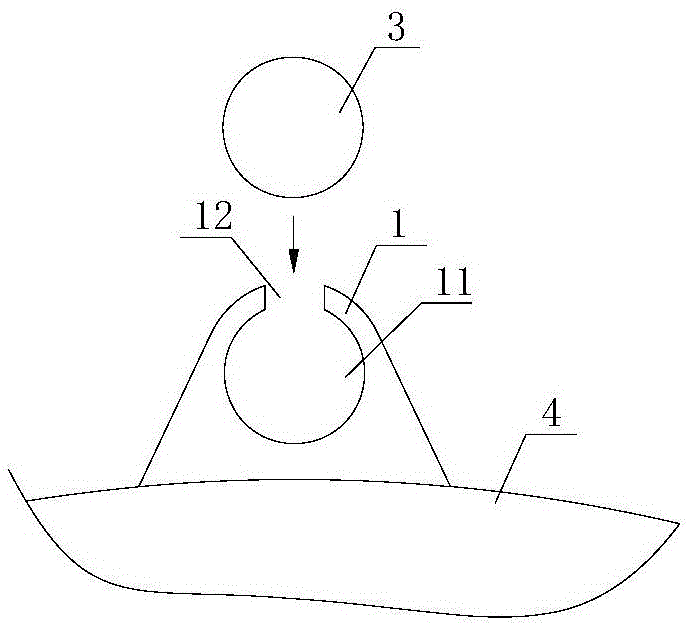

[0031] see Figure 1-3 , a method for laying a submarine pipeline leak detection optical cable, comprising the following laying steps:

[0032] 1) Arrange the pay-off rack wound with the sensor optical cable at the stern of the pipe-laying ship, and place the materials for laying on the construction site on the pipe-laying ship. Pads 1, glue and a plurality of flexible straps 2. Specifically, the optical cable installation groove is provided along the longitudinal direction of the rubber pad, and the flexible binding strip is made of non-metallic material weaving.

[0033] 2) Along the longitudinal direction of the pipeline, use glue to glue the rubber pads on the outer surface of the pipeline in the way of head-to-tail connection. Specific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com