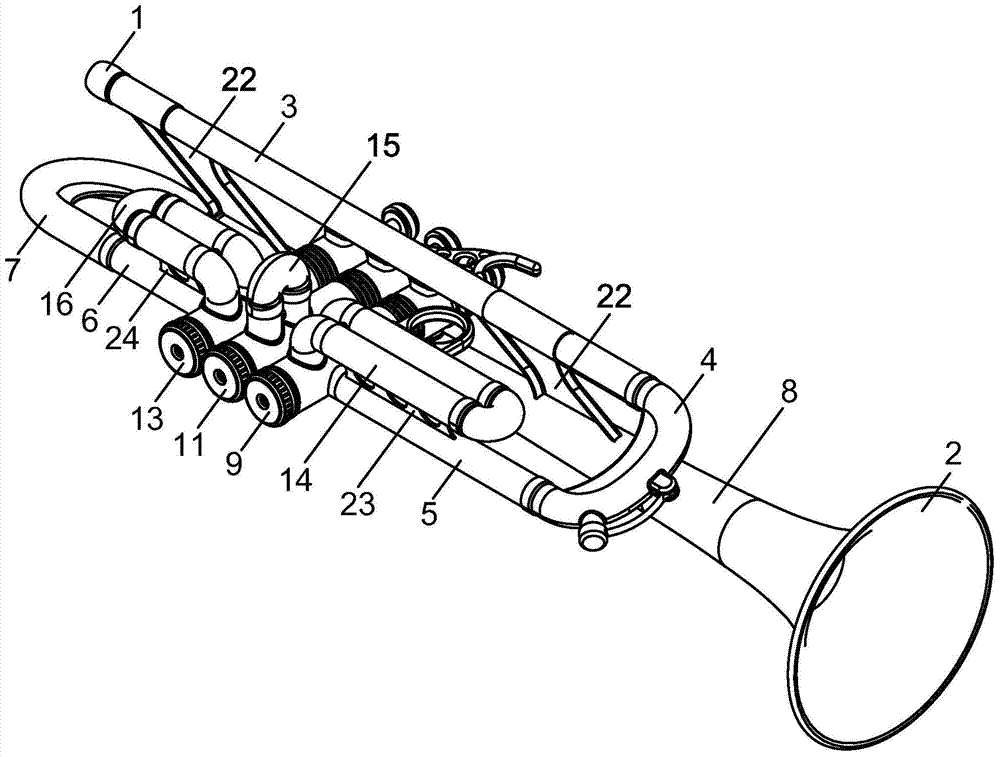

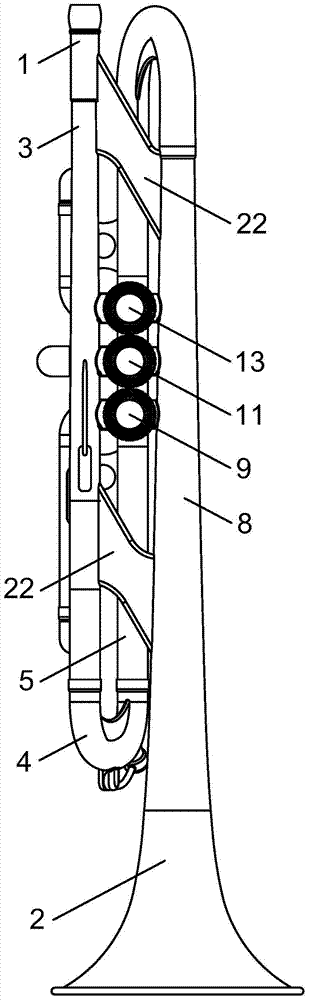

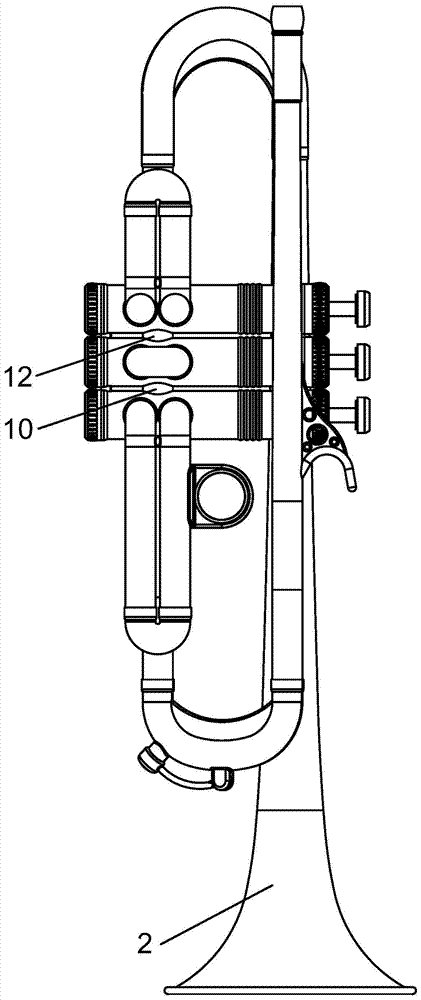

a plastic trumpet

A plastic and trumpet technology, applied in the field of musical instruments, can solve problems such as high production and maintenance costs, unreasonable air flow direction, and complicated trumpet structure, and achieve low production costs, time-saving and labor-saving production efficiency, and strong performance penetrating power Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0103] This embodiment discloses a process for increasing the strength and toughness of plastics, comprising the following steps:

[0104] 1) Bake the plastic in an oven at 100°C for 30 minutes;

[0105] 2) Put the material obtained in step 1 into boiling water and boil for 50 minutes;

[0106] 3) Dehydrate the material obtained in step 2, and then bake in an oven at a temperature of 100°C for 30 minutes;

[0107] 4) Place the material obtained in step 3 in soybean salad oil and soak for 3 hours.

[0108] After the plastic is processed by the process method, the torsion force is increased from 120Kg to 250Kg, which is about doubled, and the impact strength is increased by 75% compared with that before toughening.

Embodiment 2

[0110] This embodiment discloses a process for increasing the strength and toughness of plastics, comprising the following steps:

[0111] 1) Bake the plastic in an oven at a temperature of 120°C for 30 minutes;

[0112] 2) Put the material obtained in step 1 into boiling water and boil for 50 minutes;

[0113] 3) Dehydrate the material obtained in step 2, and then bake in an oven at a temperature of 120°C for 30 minutes;

[0114] 4) Place the material obtained in step 3 in rapeseed salad oil and soak for 4 hours.

[0115] After the plastic is processed by the process method, the torsion force is doubled from 120Kg to 240Kg, and the impact strength is increased by 75% compared with that before toughening.

Embodiment 3

[0117] This embodiment discloses a process for increasing the strength and toughness of plastics, comprising the following steps:

[0118] 1) Bake the plastic in an oven at a temperature of 80°C for 50 minutes;

[0119] 2) Put the material obtained in step 1 into boiling water and cook for 30 minutes;

[0120] 3) Dehydrate the material obtained in step 2, and then bake in an oven at a temperature of 80°C for 50 minutes;

[0121]4) Place the material obtained in step 3 in rapeseed salad oil and soak for 2 hours.

[0122] After the plastic is processed by the process method, the torsion force is doubled from 120Kg to 260Kg, and the impact strength is increased by 80% compared with that before toughening.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com