Multi-core cable

A multi-core cable and conductor technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of poor water resistance, affecting heat dissipation performance, interference, etc., and achieve the effects of good corrosion resistance, improved heat dissipation performance, and low shrinkage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

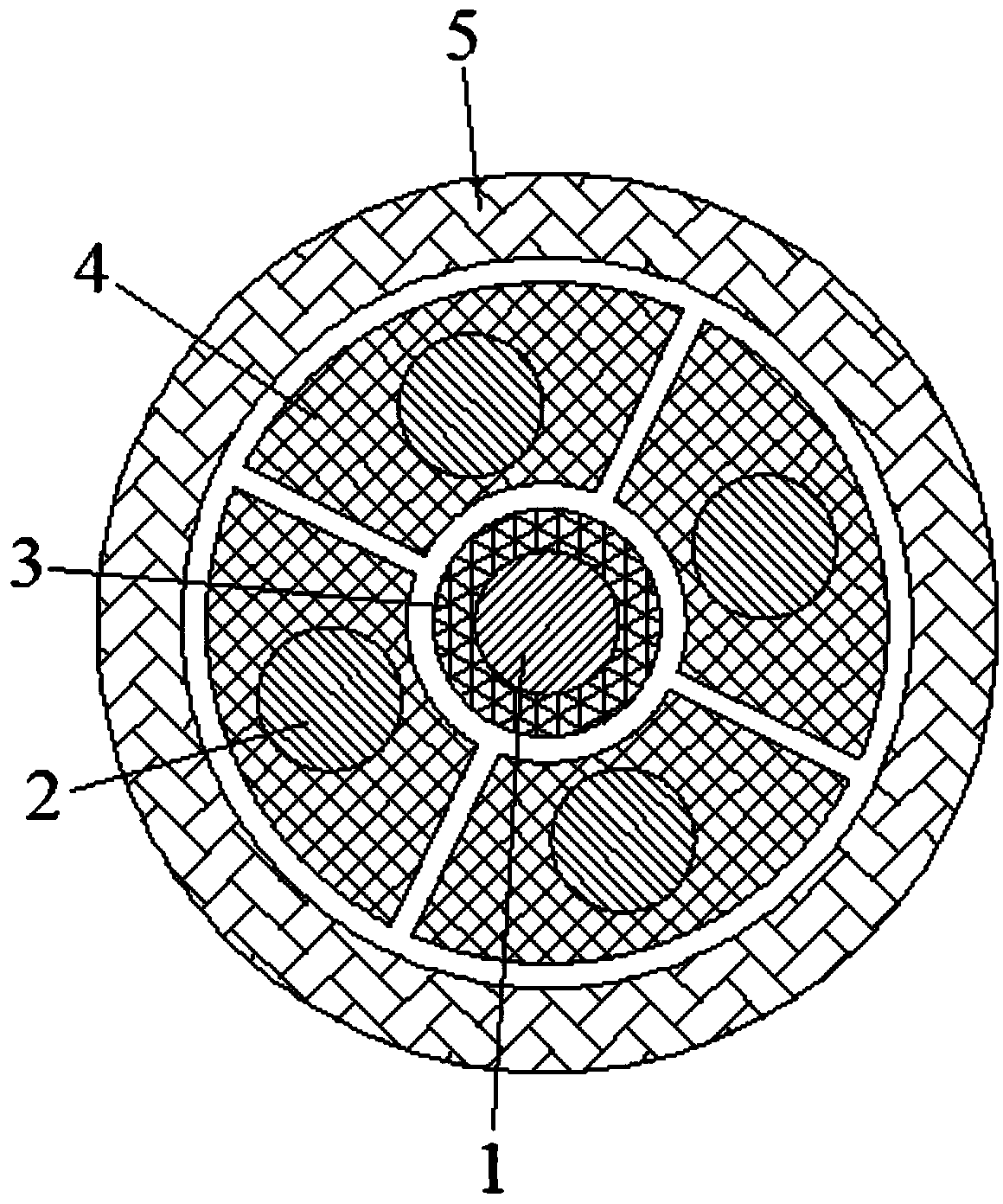

[0017] see figure 1 , a multi-core cable, including a center conductor 1 and a plurality of conductors 2, the center conductor 1 is covered with an insulating layer 3, the plurality of conductors 2 surround the center conductor 1, and the plurality of conductors 2 are respectively covered There is an insulating layer 4 with a fan-shaped cross section. There are gaps between the insulating layer 3 outside the central conductor 1 and the insulating layer 4 outside the multiple conductors 2 and between the insulating layers outside the two adjacent conductors. The insulating layer 4 is covered with a sheath 5 .

[0018] In the present invention, there is a gap between the insulating layer outside the plurality of conductors 2 and the sheath 5 .

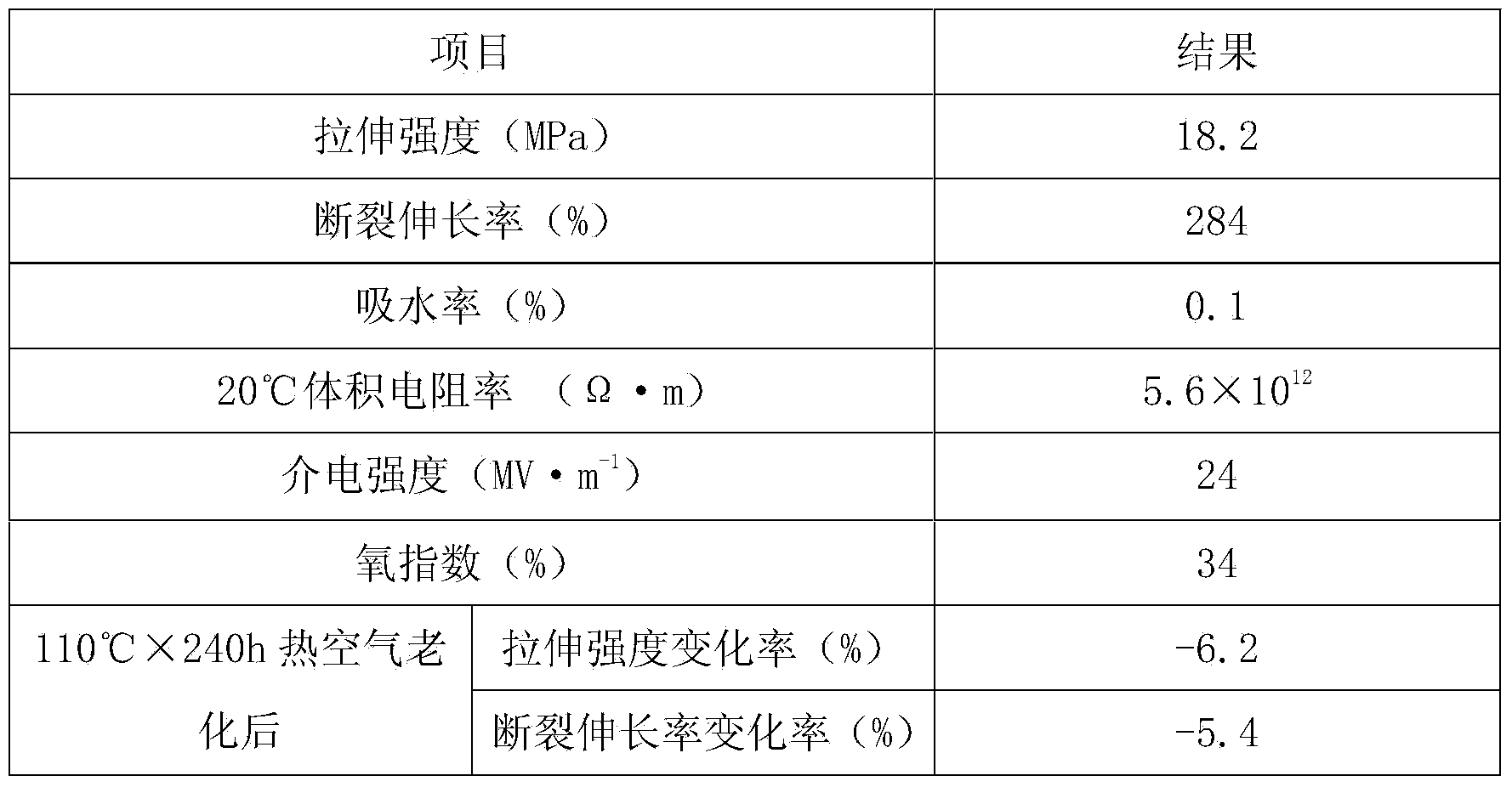

[0019] The material of the sheath 5 is made of the following raw materials by weight (kg): high-density polyethylene 75, polyphenylene sulfide 15, polyethylene terephthalate 10, antimony trioxide 14, zinc borate 8, carbon black N66025,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com