Battery heat management system with heat pipes with temperature self-adaption function coupled to single-phase liquid loop to transfer heat

A battery thermal management and coupled heat exchange technology, applied in batteries, secondary batteries, circuits, etc., can solve the problems of reduced heat transfer performance, difficulty in battery heat, failure, etc., to save energy, ensure safe and stable operation, and ensure use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

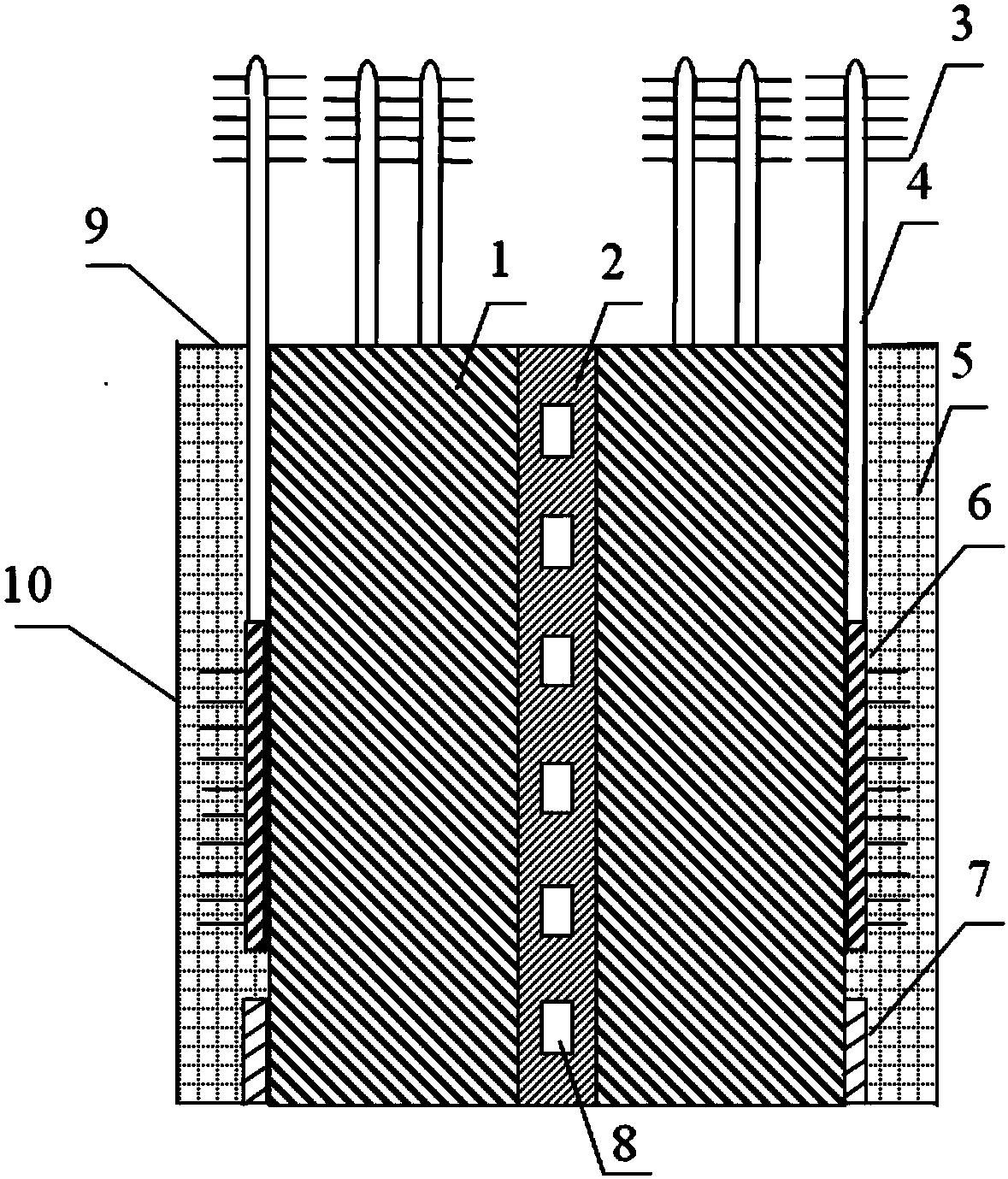

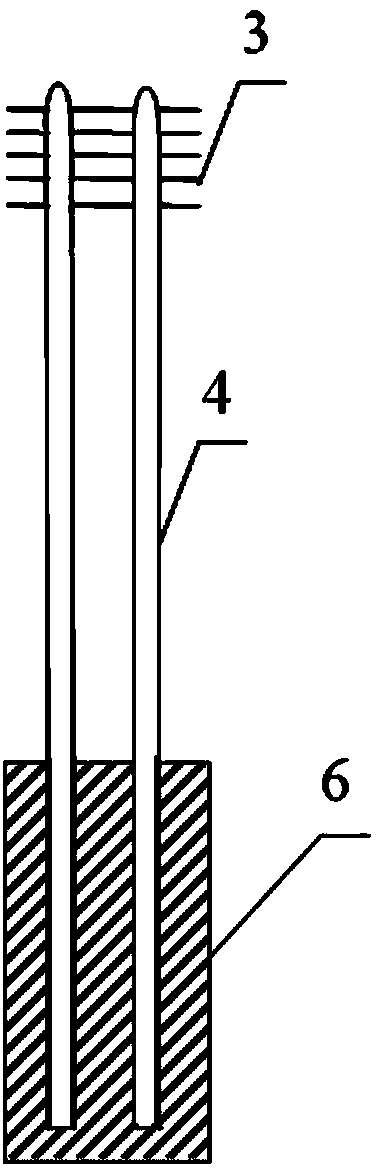

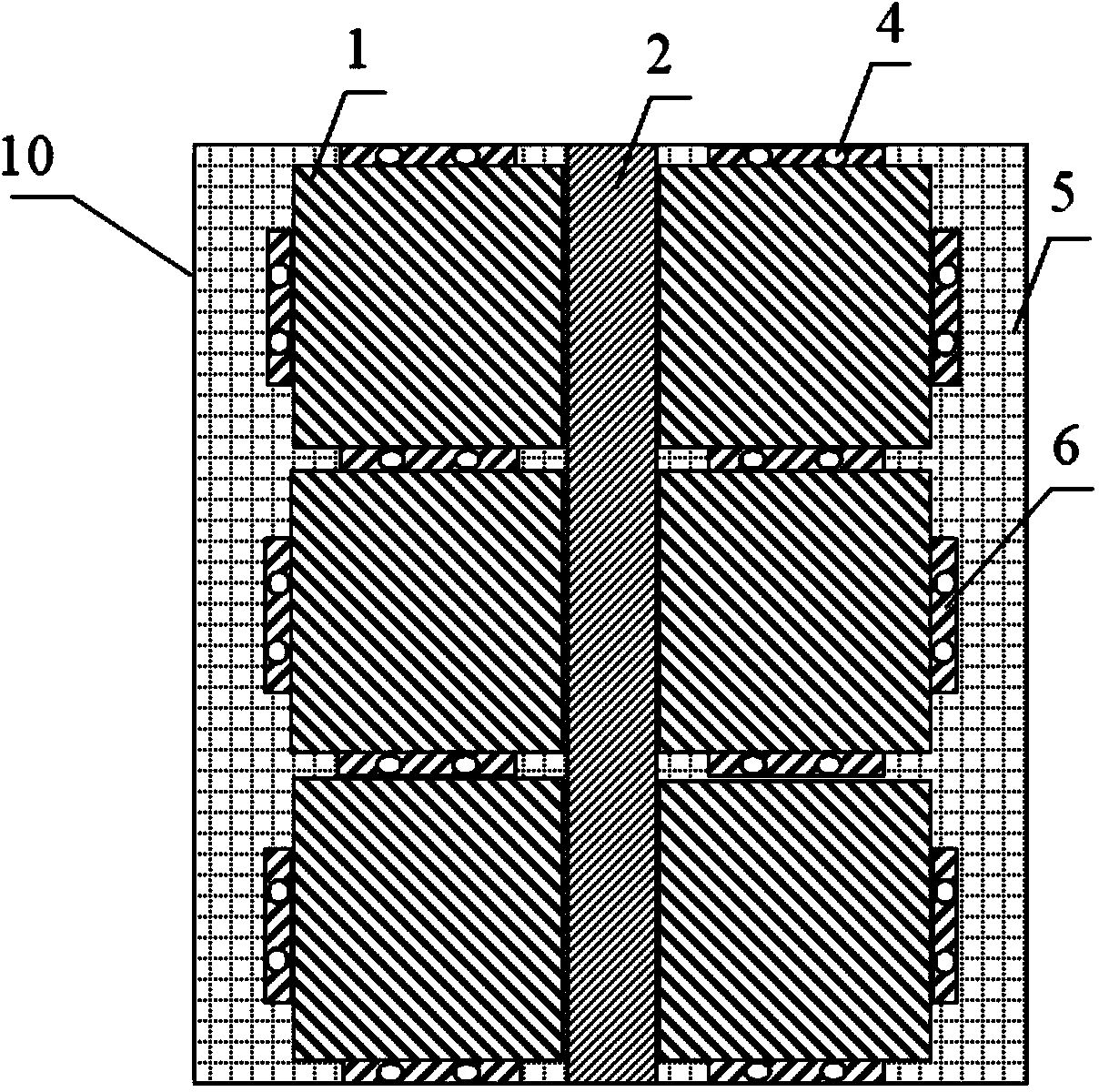

[0032] Specific embodiments: The battery heat management system of this embodiment that couples heat exchange with a heat pipe with a temperature adaptive function and a single-phase liquid circuit includes a power battery box, and the power battery box includes a battery box shell 10, a battery box top cover 9, and a power battery The battery card slot 7 inside the box, the battery box top cover 9 and the battery box shell 10 cooperate, and the battery thermal management system also includes a cold plate 2, a heat pipe 4 and a heat pipe evaporation section 6;

[0033] A cold plate 2 is embedded in the center of the power battery box. A plurality of single power batteries 1 are installed in the card slot 7 of the power battery box and arranged on the left and right sides of the cold plate 2. The single power batteries 1 are fastened to the battery card. Between the groove 7 and the cold plate 2, in this way, it can ensure that the position of the single power battery 1 does not...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com