Methods for producing polyolefins with catalyst systems

A technology of polyolefin and catalyst, which is applied in the field of polyolefin production by using catalyst system, and can solve the problems of activator dosage obstacle and expensive activator, etc.

Active Publication Date: 2014-07-16

UNIVATION TECH LLC

View PDF81 Cites 17 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Unfortunately, these activators are expensive, and the amount of activators required to produce active polymerization catalysts is a serious obstacle to commercializing metallocene catalysts for the production of polyolefins

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0142] In order to provide a better understanding of the foregoing discussion, the following non-limiting examples are provided. All parts, ratios and percentages are by weight unless otherwise indicated.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Login to View More

Abstract

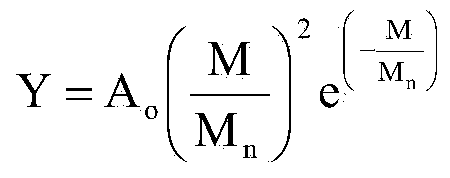

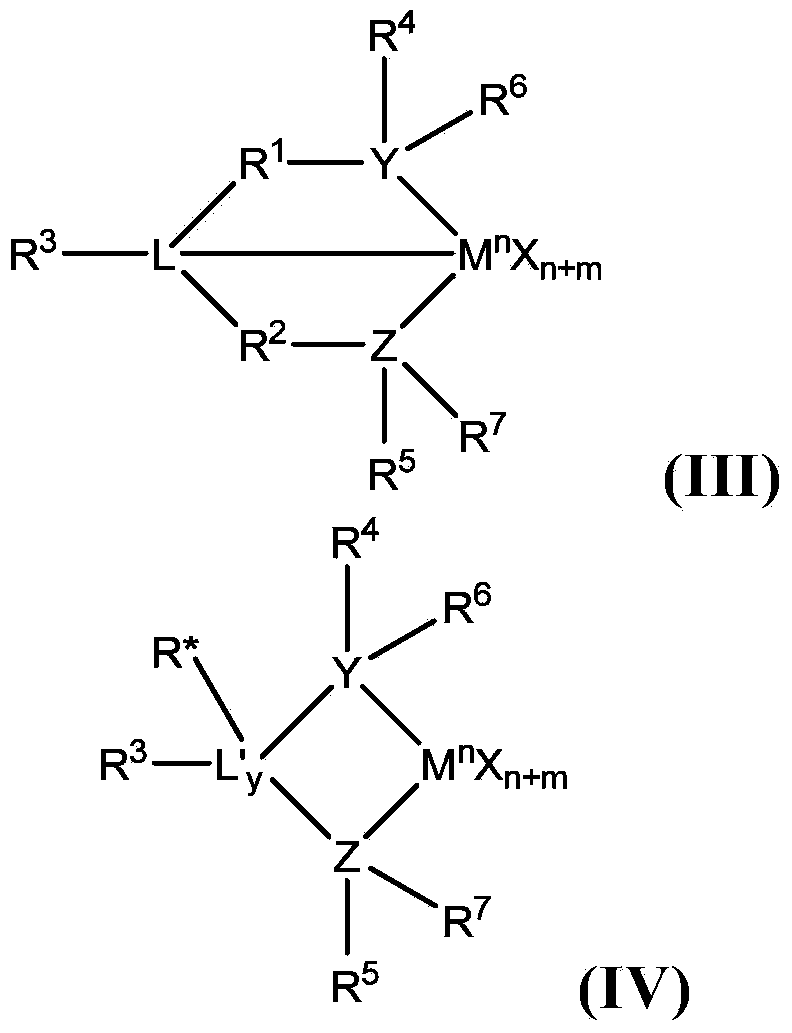

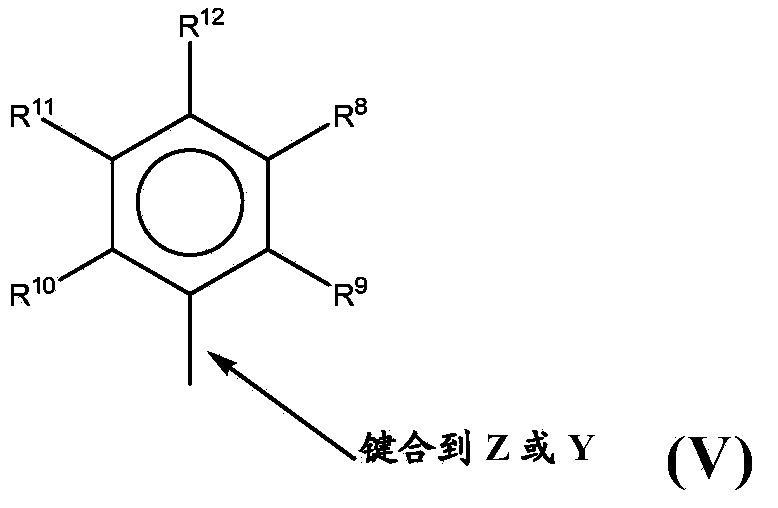

Described herein are methods comprising contacting one or more olefins with a catalyst system in a polymerization reactor at conditions sufficient to produce a polyolefin, wherein the catalyst system comprises a first metallocene catalyst compound comprising a first transition metal atom, two cyclopentadienyl ligands bound to the first transition metal atom, and two leaving groups bound to the first transition metal atom, wherein at least one leaving group is selected from the group consisting of a halo-phenoxy and a halo-alkoxy; wherein the first metallocene catalyst compound has a catalyst productivity that is at least 20% greater than a comparative metallocene catalyst compound used to produce the same polyolefin, wherein the comparative metallocene catalyst compound is the same as the first metallocene catalyst compound except neither leaving group is a halo-phenoxy or a halo-alkoxy.

Description

Background technique [0001] A number of catalyst compositions containing single-site catalysts have been used to prepare polyolefins to produce relatively uniform copolymers. In contrast to conventional multi-site Ziegler-Natta catalyst compositions, single-site catalysts, such as metallocene catalysts, are catalytic compounds that contain uniform polymerization sites. [0002] To achieve acceptable and commercially viable polymerization activity with metallocene catalyst compounds, large amounts of activators, such as methylaluminoxane ("MAO"), are often required. Unfortunately, these activators are expensive, and the amount of activator required to produce active polymerization catalysts has been a serious obstacle to commercializing metallocene catalysts for the production of polyolefins. Therefore, there is a need for catalysts with improved activity and productivity and thus requiring less activator. [0003] Mixed catalyst systems often include at least one metallocene...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08F210/16C08F10/02C08F4/659C08F4/64

CPCC08F4/6592C08F4/65925C08F4/65927C08F10/00C08F4/65904C08F210/16C08F2410/01C08F4/659C08F10/02C08F4/64148C08F210/14C08F2500/12C08F2500/05

Inventor 孙立新F·C·里克斯高珊爵P·A·库克哈尼P·A·曹

Owner UNIVATION TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com