Method and apparatus for liquid level loop control

A loop control and liquid level technology, applied in the field of control systems, can solve problems such as blockage, liquid ingress, and rupture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

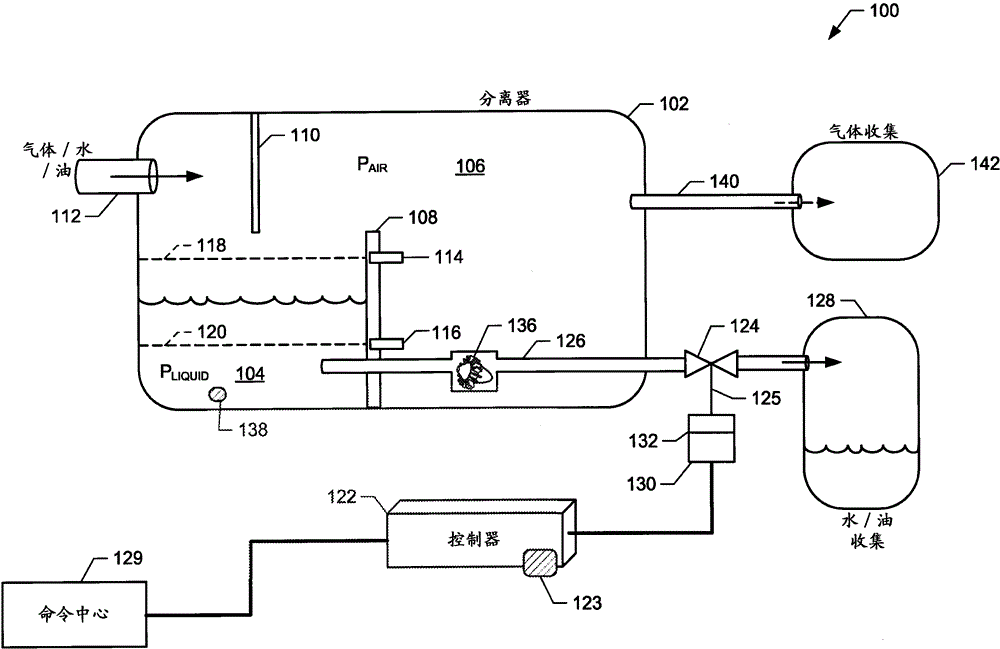

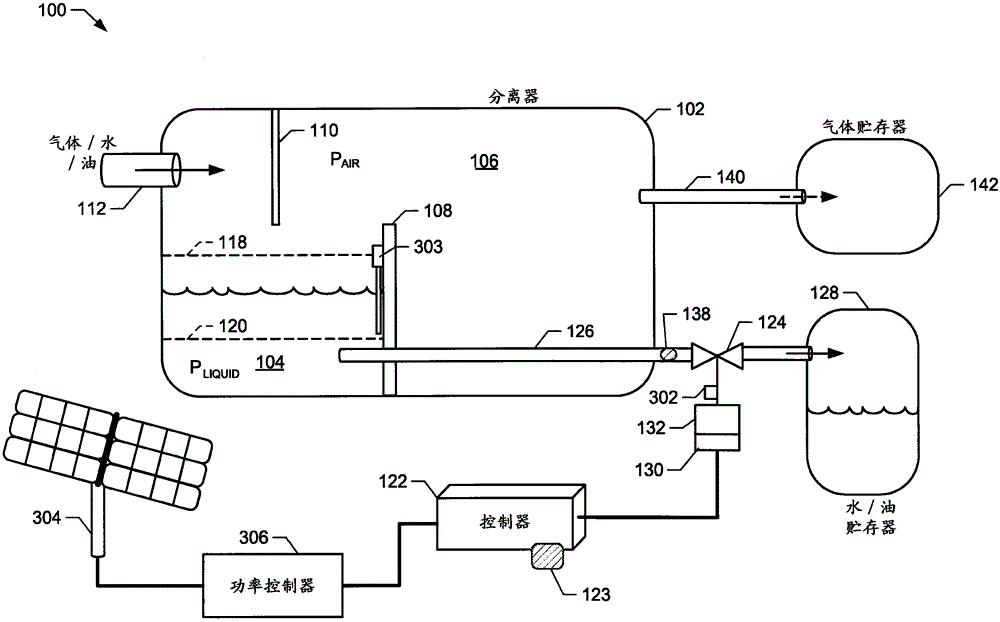

[0012] While the following describes exemplary methods and apparatus that include, among other components, software and / or firmware executed on hardware, it should be noted that this system is exemplary only and should not be viewed as limiting. For example, it is contemplated that any or all of these hardware, software, and firmware components may be implemented exclusively in hardware, exclusively in software, or in a combination of hardware and software. Thus, although the exemplary methods and apparatus described below in connection with a natural gas well site, the exemplary methods and apparatus may be used in any application to separate gases from liquids.

[0013] Natural gas well sites extract unrefined natural gas from underground natural reserves. Natural gas extracted from the ground is in a fluid mixture of liquids, slurries and gases. One of the first steps is to purify the natural gas to separate any liquids, slurry and / or water vapor from the gas so that the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com