A kind of uv light curing equipment

A light curing and equipment technology, applied in the direction of pretreatment surface, coating, surface coating liquid device, etc., can solve the problems of poor drying effect, inability to dry on multiple surfaces and angles, and uneven drying, etc. Achieve the effect of avoiding excessive internal temperature and uniform drying of multiple surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is described below in conjunction with accompanying drawing.

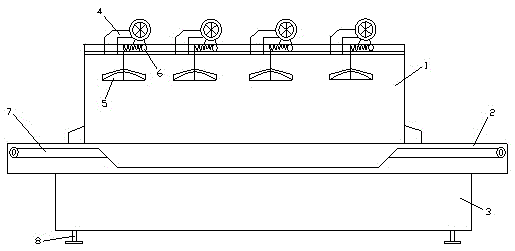

[0012] refer to figure 1 As shown, a UV photocuring equipment includes a photocuring device 1, a transportation device 2 and a base 3, and the photocuring device 1, transportation device 2 and base 3 are connected sequentially from top to bottom, and the top of the photocuring device 1 More than one blower 4 is provided, and there are corresponding ventilation holes (not shown) near the blower 4, and a UV light-fixing lamp 5 is arranged under each blower 4, and the position of the UV light-fixing lamp 5 and the blower 4 is relatively close. And the main heat source of the general UV light curing equipment is the UV light curing lamp 5, and the blower 4 arranged above the UV light curing lamp 5 can achieve the effect of heat dissipation at the heat source, and the heat dissipation performance is better. The UV light curing lamp 5 For the hanging setting, the UV light curing lamp 5 is eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com