Film-coated injection-molding damp-proof container and manufacturing method thereof

A manufacturing method and container technology, applied in the directions of containers, rigid containers, flexible coverings, etc., can solve the problems of rising transportation costs of plastic containers, increasing production costs of plastic containers, etc., so as to save the cost of stacking packaging and transportation, external visual Good effect and the effect of reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0028] The technical scheme of concrete implementation of the present invention is:

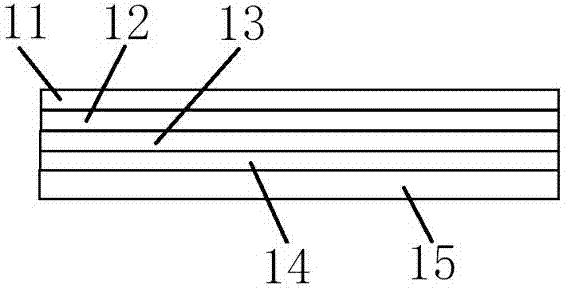

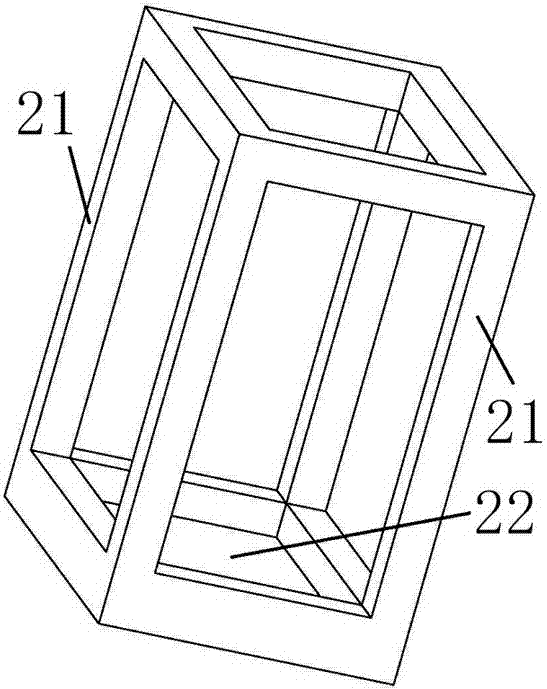

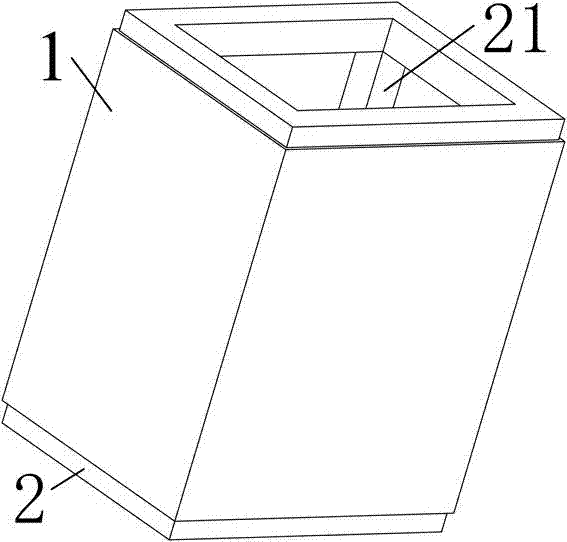

[0029] Such as Figure 1 to Figure 3 As shown, a film-coated injection molded moisture-proof container is composed of an injection molding part 2 and an outer coating film 1, and the outer coating film 1 is coated on the side peripheral wall of the container; the injection molding part 2 constitutes a three-dimensional structure of the side peripheral wall of the container. skeleton, and container bottom 22;

[0030] The injection molding part 21 of the injection molded part 2 located on the side peripheral wall of the container only constitutes the three-dimensional ske...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap