Bobbin holding rack

A technology for placing racks and bobbins, applied in the directions of external frame, transportation and packaging, packaging, etc., can solve the problems of poor practical performance, high use cost, easy falling off of bobbins, etc., and achieves convenient operation, good practical performance and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

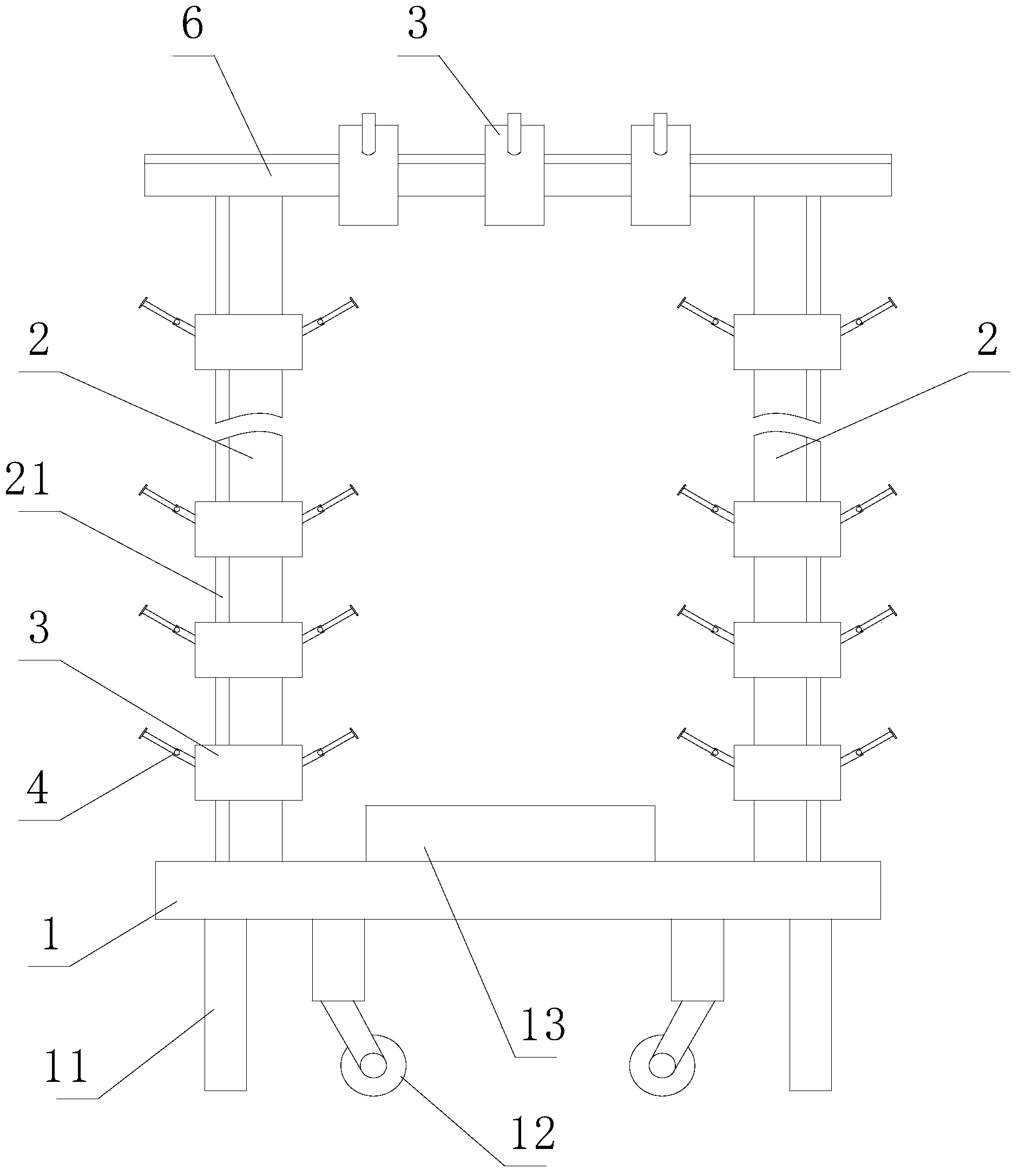

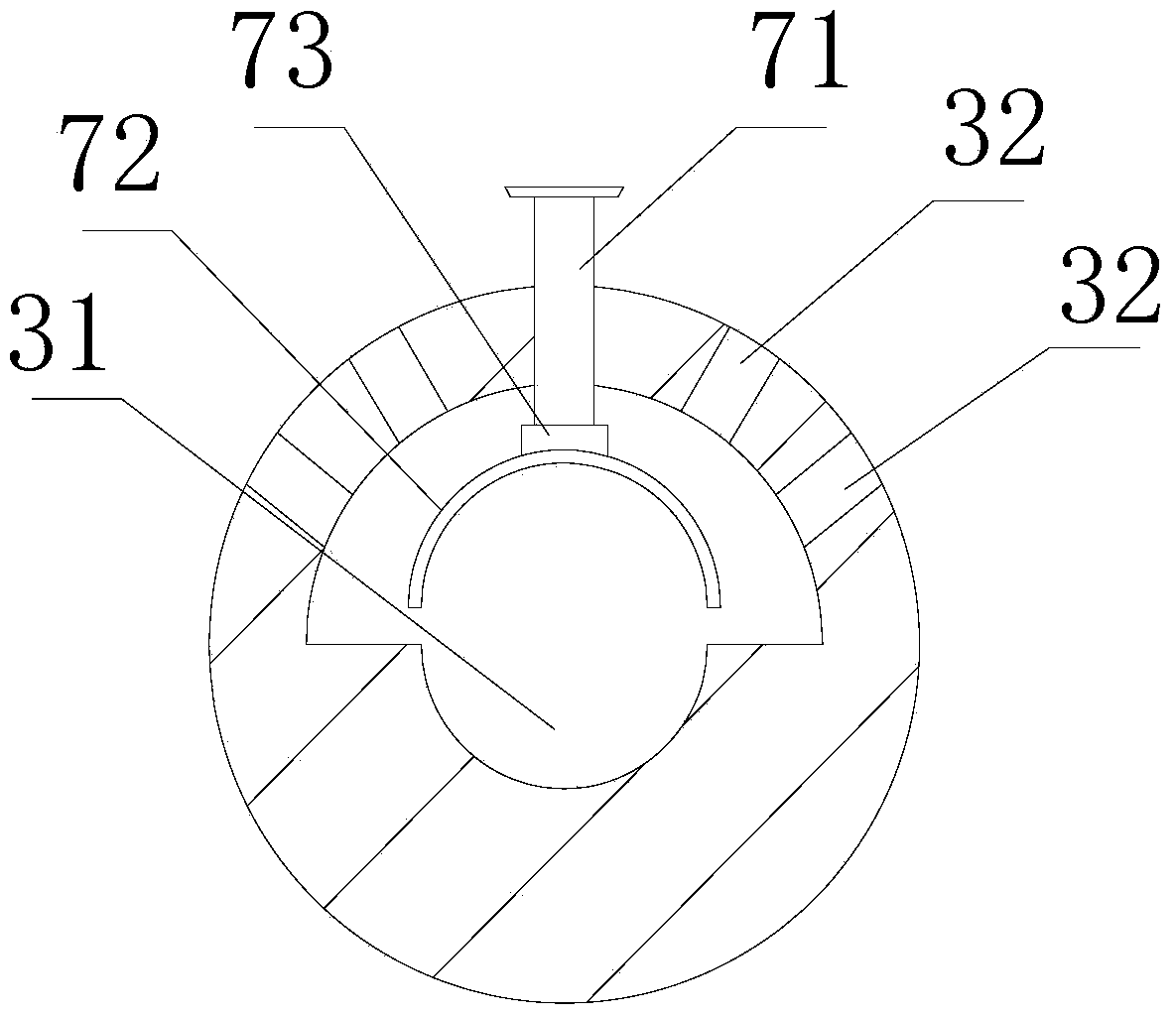

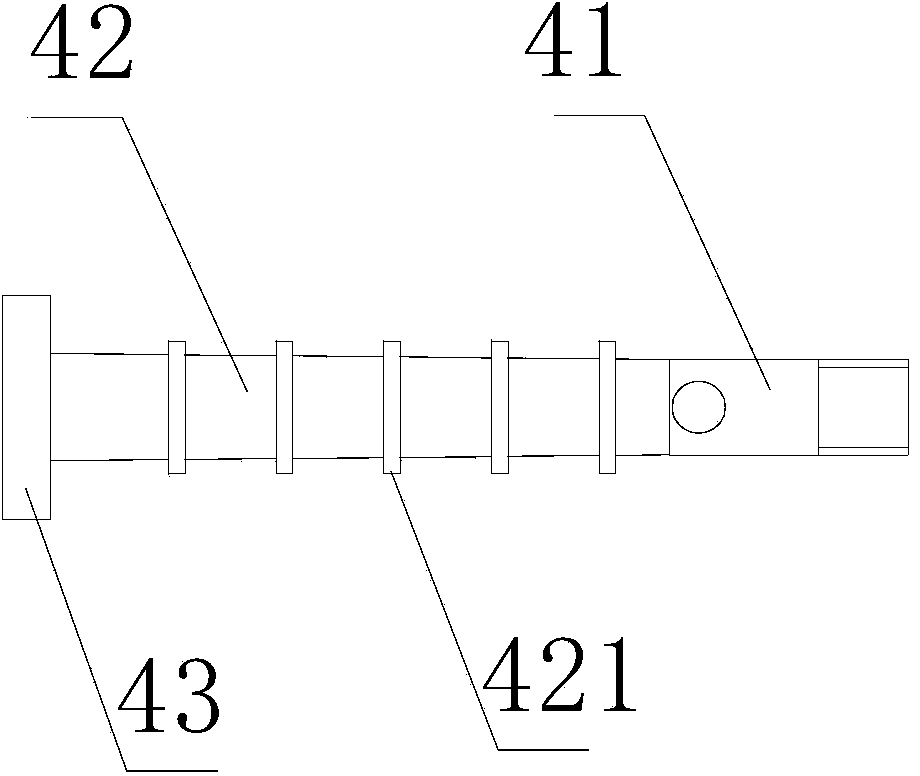

[0014] Such as figure 1 , figure 2 , image 3 As shown, a bobbin placement frame includes a base plate 1, at least two vertical connecting rods 2 fixedly connected to the base plate 1, and each of the vertical connecting rods 2 is provided with several slidingly connected vertical connecting rods. The sleeve 3 on the connecting rod 2 has an eccentric hole 31 with a large top and a small bottom in the middle of the sleeve 3. The diameter of the lower half of the eccentric hole 31 is equal to the diameter of the vertical connecting rod 2. The sleeve 3 on the upper half of the hole 31 is provided with an inclined portion 4 inclined upwards with respect to the horizontal axis. The placing rod 42 for placing the bobbin on the sleeve 3 is provided with a locking device 7 that locks the sleeve 3 on the vertical connecting rod 2, and the locking device 7 includes a flexible connection on the sleeve The screw rod 71 on the cylinder 3, the pressing piece 72 fixedly connected on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com