Metering belt type feeder free of carrier rollers

A feeder, rollerless technology, applied in the field of material metering and conveying equipment, can solve the problems of increasing conveyor belt friction and dust, increasing transmission resistance, inaccurate metering, etc., to reduce friction, reduce conveying resistance, and improve metering. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

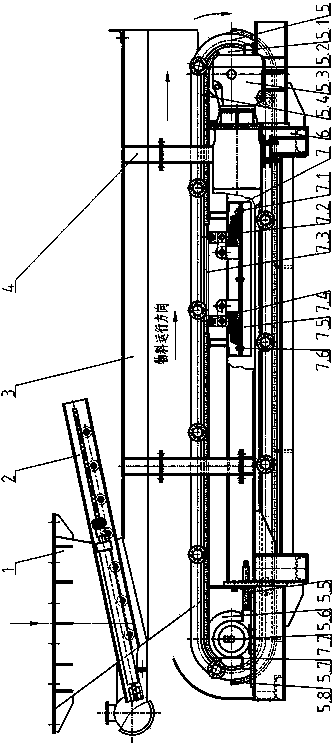

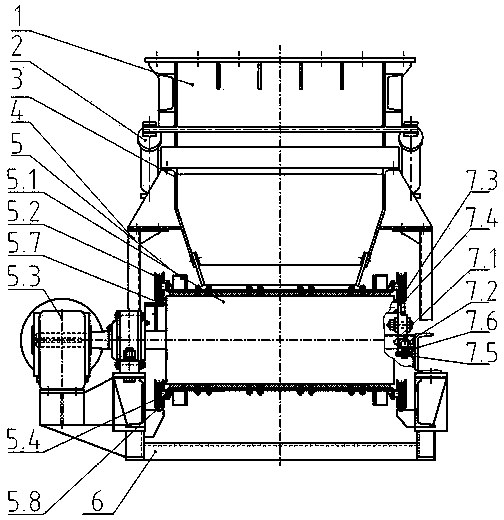

[0020] control Figure 1~5 , The present invention does not have roller metering belt feeder, is made up of funnel, gate, guide trough body, conveying system, weighing system and chassis. Its specific structural features are: the upper part of the funnel 1 is connected to the mouth of the hopper, the lower part is provided with a gate 2 and a material guide trough 3, and a conveying system 5, a weighing system 7, and a support 4 are arranged under the material guide trough 3 The upper and lower parts of the upper and lower parts are respectively connected with the material guide trough body 3 and the underframe 6, and the conveying system 5 and the weighing system 7 are connected with the underframe 6 respectively.

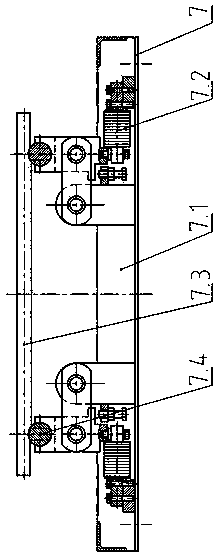

[0021] The bearing housings of the driving roller 5.1 and the redirecting roller 5.6 of the conveying system 5 are respectively connected with the chassis 6, and an annular conveyor belt 5.4 is arranged between the two rollers, and several pairs of belt grooves ar...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap