A kind of method that utilizes fly ash to prepare ceramic floor

A technology of fly ash and ceramics, which is applied in the field of comprehensive utilization of industrial solid waste, can solve problems such as high cost of ceramic flooring, environmental pollution, and insufficient use of fly ash, so as to increase added value, reduce site resources, and realize resource utilization. The effect of chemical utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

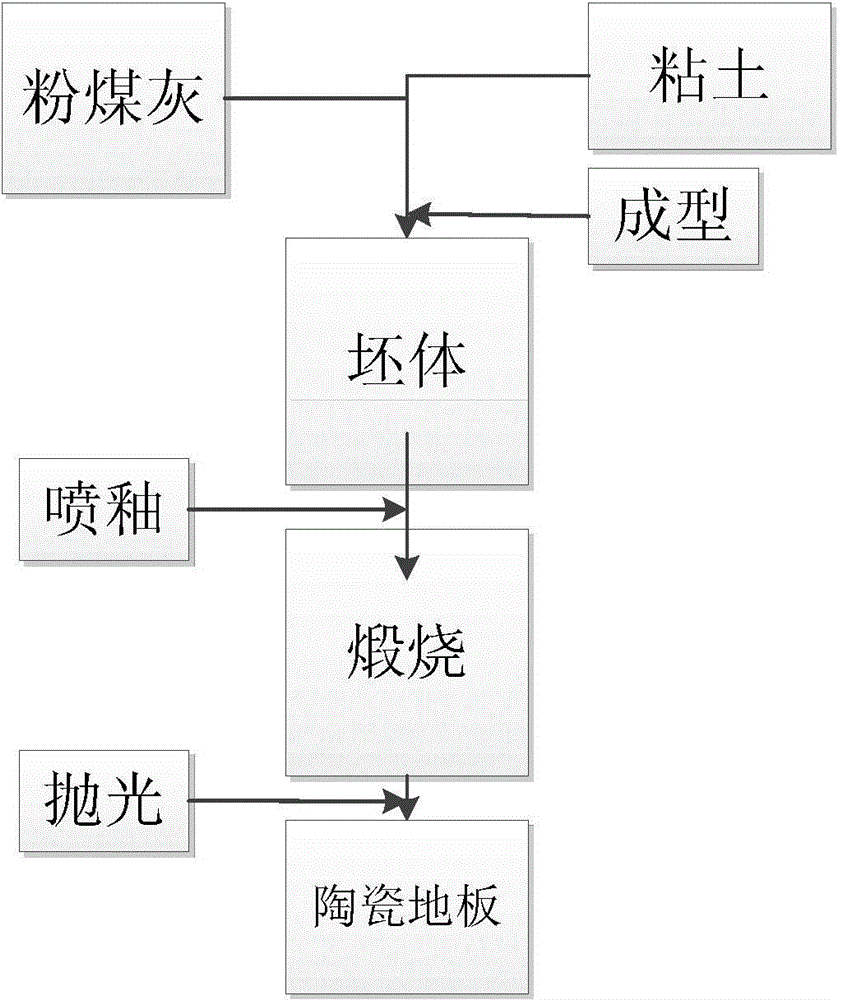

[0030] Embodiment 1: as figure 1 As shown, 70 parts of fly ash and 30 parts of Tangshan clay were put into a mixer and stirred for 10 hours, then dried in a dryer at 85°C for 10 hours, and then put into a granulator for granulation. Granular materials are high-pressure molded under 60MPa pressure to make solid ceramic floor substrate boards. The boards are sequentially cooled, cut to length, hole plugging, grinding, grooving, tenoning, fine grinding, and scrubbing. Spray a layer of glaze evenly on its surface. Calcined at 1200°C for 3 hours to obtain a vitrified glaze layer. The vitrified glaze layer on the surface is then ground, polished and flattened to obtain a ceramic floor product.

Embodiment 2

[0031] Embodiment 2: as figure 1 As shown, 60 parts of fly ash and 40 parts of Tangshan clay were put into a mixer and stirred for 10 hours, then dried in a dryer at 85°C for 10 hours, and then put into a granulator for granulation. Granular materials are high-pressure molded under 60MPa pressure to make solid ceramic floor substrate boards. The boards are sequentially cooled, cut to length, hole plugging, grinding, grooving, tenoning, fine grinding, and scrubbing. Spray a layer of glaze evenly on its surface. Calcined at 1400°C for 3 hours to obtain a vitrified glaze layer. The vitrified glaze layer on the surface is then ground, polished and flattened to obtain a ceramic floor product.

[0032] Compared with Example 2, the amount of fly ash added in Example 1 is larger, and the color of the obtained ceramic floor body is darker, but after spraying a layer of glaze, no difference can be seen from the surface.

[0033] The final ceramic floor can refer to figure 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com