Drag reducer, and preparation method thereof

A technology of drag reducing agent and isolating agent, applied in mechanical equipment, pipeline system, gas/liquid distribution and storage, etc., can solve the problems of loss of light oil content, affecting the normal transportation of crude oil, etc. The effect of drag reducing polymer particle suspension system and storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] This example is used to illustrate the preparation method of the composite release agent.

[0043] Add 9.8g of maleic anhydride and 100mL of toluene into a three-necked flask, raise the temperature to reflux temperature to dissolve the maleic anhydride, cool down to 80°C, add 0.24g of dodecanethiol and 10.3g of styrene, keep the reaction temperature at 80°C, and dissolve the peroxide Dissolve 0.24g of benzoyl (BPO) in 30mL of toluene, slowly add it dropwise into a three-neck flask, keep it warm for 4 hours, during which the copolymer of styrene-maleic anhydride is continuously precipitated, filter, and put the filter cake at 80°C Vacuum drying yielded 17.2 g of styrene-maleic anhydride copolymer.

[0044] Take 17.2g of the above-mentioned styrene-maleic anhydride copolymer, add 34.4g of montmorillonite, 80g of stearyl alcohol, 120mL of toluene, 0.8g of p-toluenesulfonic acid, heat up to the reflux temperature, and react for 4h, during which the styrene-maleic anhydride ...

Embodiment 2

[0046] This example is used to illustrate the preparation method of polyalphaolefin / simethicone oil slurry.

[0047] The polymerization catalyst used is prepared according to the following method: add 2.0 grams of ethoxymagnesium particle carrier (particle diameter is 40-50 microns), toluene 30ml into the reaction bottle and disperse evenly, lower the temperature to -10°C, add 10ml (6.0mol )TiCl 4 , stay for 0.5 hours, heat up to 80°C, add 0.6ml (0.39mol) diisobutyl phthalate, heat up to 110°C for 2 hours, settle, filter, wash with toluene twice (20ml each time), twice Load titanium, add 5ml (3.0mmol) TiCl 4 React with 30ml of toluene for 1 hour, settle, filter, wash with hexane four times, and dry at 72°C to obtain a catalyst solid component. The mass percent content of titanium in the catalyst is 2.87%.

[0048] Mix 35g of 1-octene refined by molecular sieves (purchased from ACROS Reagent Company) with 65g of dimethicone oil refined by molecular sieves (purchased from Bei...

Embodiment 3

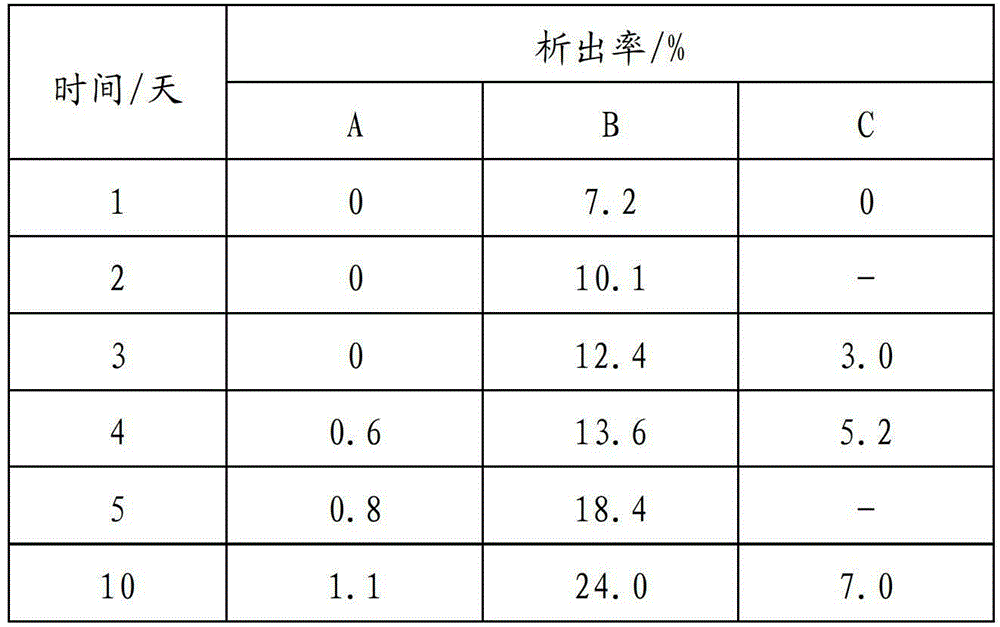

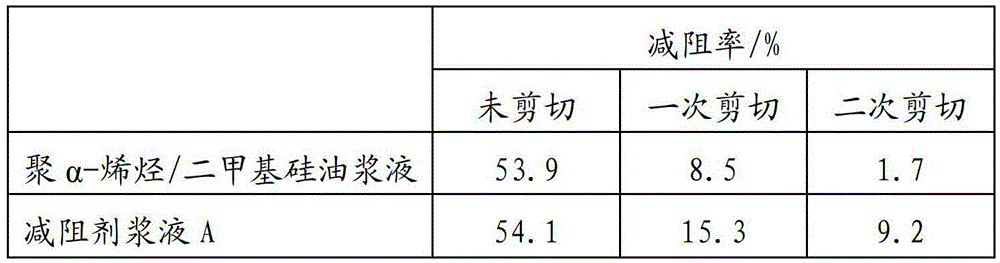

[0050] Prepare the polyalpha-olefin / dimethyl silicone oil slurry in the same manner as in Example 2. After the polymerization reaction, add 9 g of the composite release agent of Example 1 to the slurry, stir for 30 min, add 2 g of sodium petroleum sulfonate, and stir for 30 min. The drag reducer slurry A was obtained, and the storage stability is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com