A preparation method of phosphorylated krill peptide capable of preventing and treating osteoporosis

A technology of phosphorylated krill and krill, applied in bone diseases, hydrolyzed protein components, food science, etc., can solve the problems of unreported functional ingredients, achieve no environmental pollution, high product safety, and prevent and treat osteoporosis Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] (1) Take 10 kg of Antarctic krill powder, add 100 L of 95% ethanol, stir in the reaction kettle for 6 hours, centrifuge to collect the precipitate, and dry it in vacuum to obtain defatted krill powder;

[0015] (2) Add 80L NaOH solution to defatted krill powder, stir and extract at 60°C for 40min, centrifuge to obtain supernatant A;

[0016] (3) Add 6M HCl to the supernatant A, adjust the pH value of the supernatant A to the isoelectric point, let it stand for 20 minutes, and centrifuge to obtain the precipitate B. Add 5 times the volume of water and 0.2M potassium pyrophosphate to the solution, and add to the solution Add 2M HCl to the solution, adjust the pH value of the solution to 2.5, and spray dry to obtain krill protein powder;

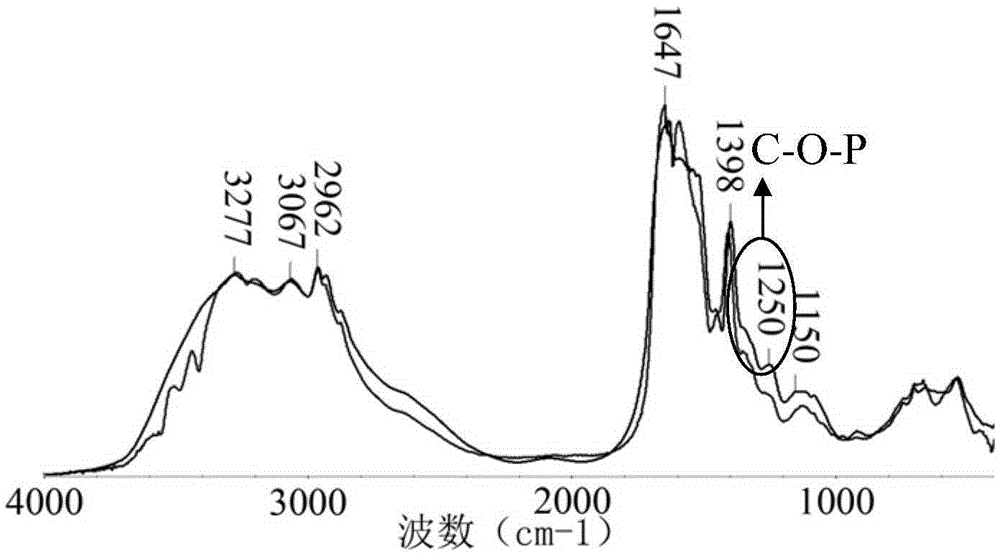

[0017] (4) Phosphorylated krill protein powder was obtained by heating krill protein powder at 80°C for 48 hours to obtain phosphorylated krill protein powder;

[0018] (5) Add 5 times the volume of water to the phosphorylated protein p...

Embodiment 2

[0021] (1) Take 10kg of Antarctic krill powder, add 80L of 95% ethanol, stir in the reaction kettle for 7 hours, separate the precipitate, and dry it in vacuum to obtain defatted krill powder;

[0022] (2) Add 70L NaOH solution to defatted krill powder, stir and extract at 50°C for 60 minutes, centrifuge to obtain supernatant A;

[0023] (3) Add 4M HCl to the supernatant A, adjust the pH value of the supernatant A to the isoelectric point, let it stand for 30 minutes, and centrifuge to obtain the precipitate B. Add 6 times the volume of water and 0.15M sodium metaphosphate to the solution. Add 2M HCl to the solution, adjust the pH value of the solution to 3.5, and spray dry to obtain krill protein powder;

[0024] (4) Krill protein powder was heated at 85°C for 24 hours for phosphorylation and derivatization to obtain phosphorylated krill protein powder;

[0025] (5) Add 6 times the volume of water to the phosphorylated krill protein powder, mix well, and centrifuge to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com