A vacuum annealing furnace

A vacuum annealing furnace and furnace technology, applied in the field of vacuum annealing furnace, can solve the problems that the temperature of the workpiece may only be about 500°C, the holding time, temperature difference, and heat treatment effect are different, etc., and achieve good annealing quality of the workpiece, heating transmission Heats up quickly and shortens the heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is described in further detail by the following examples.

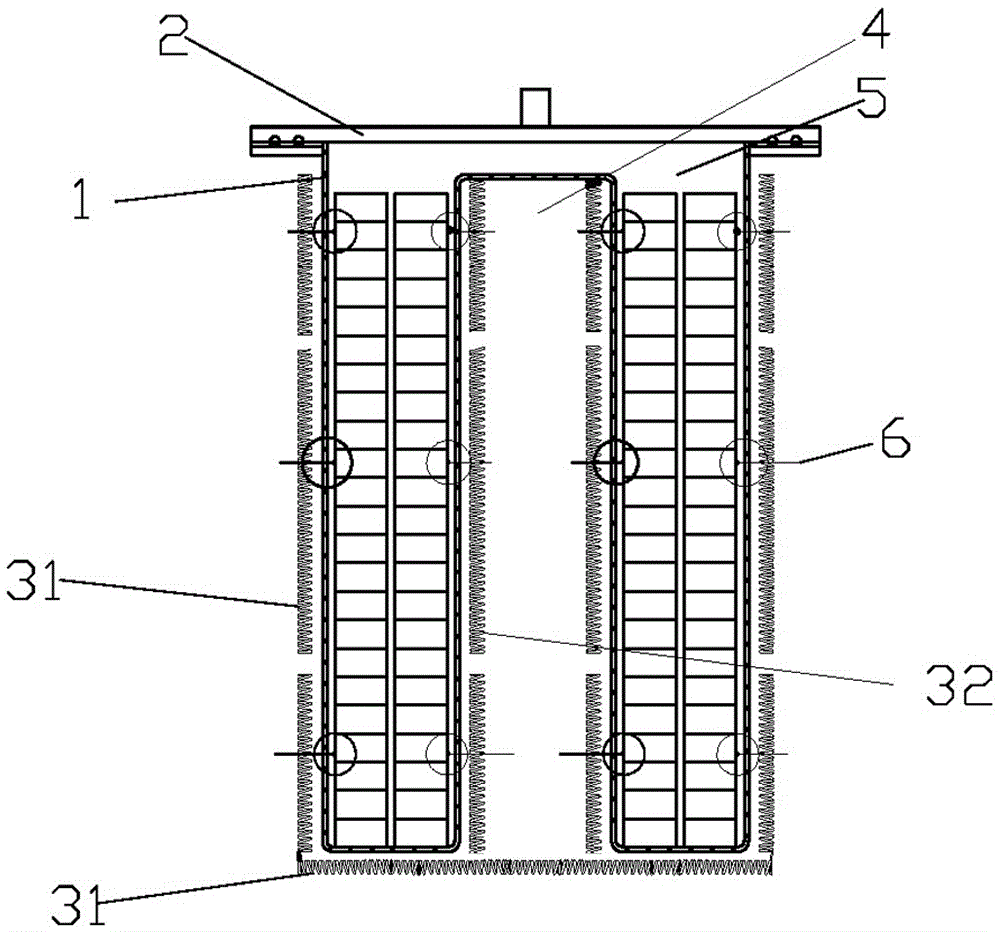

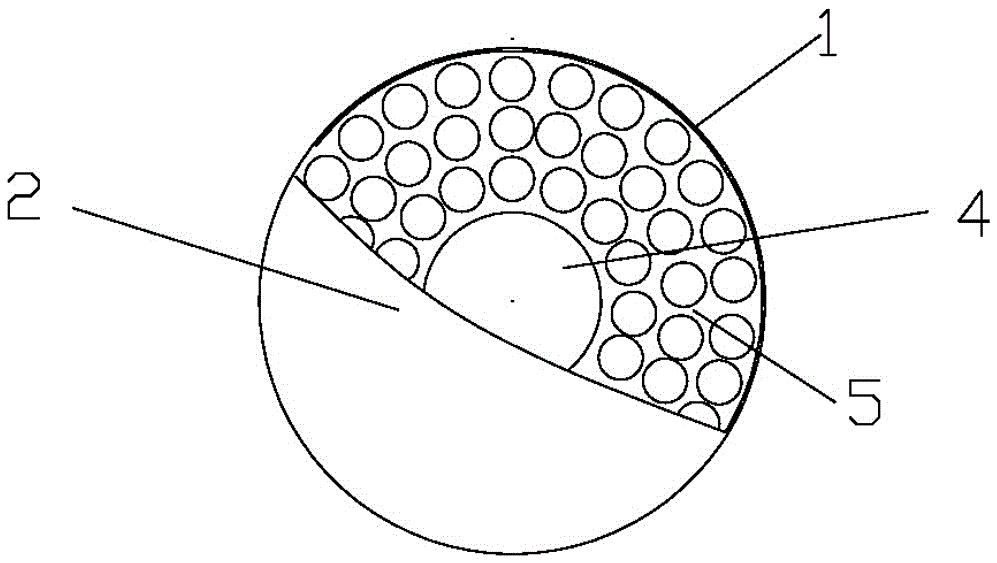

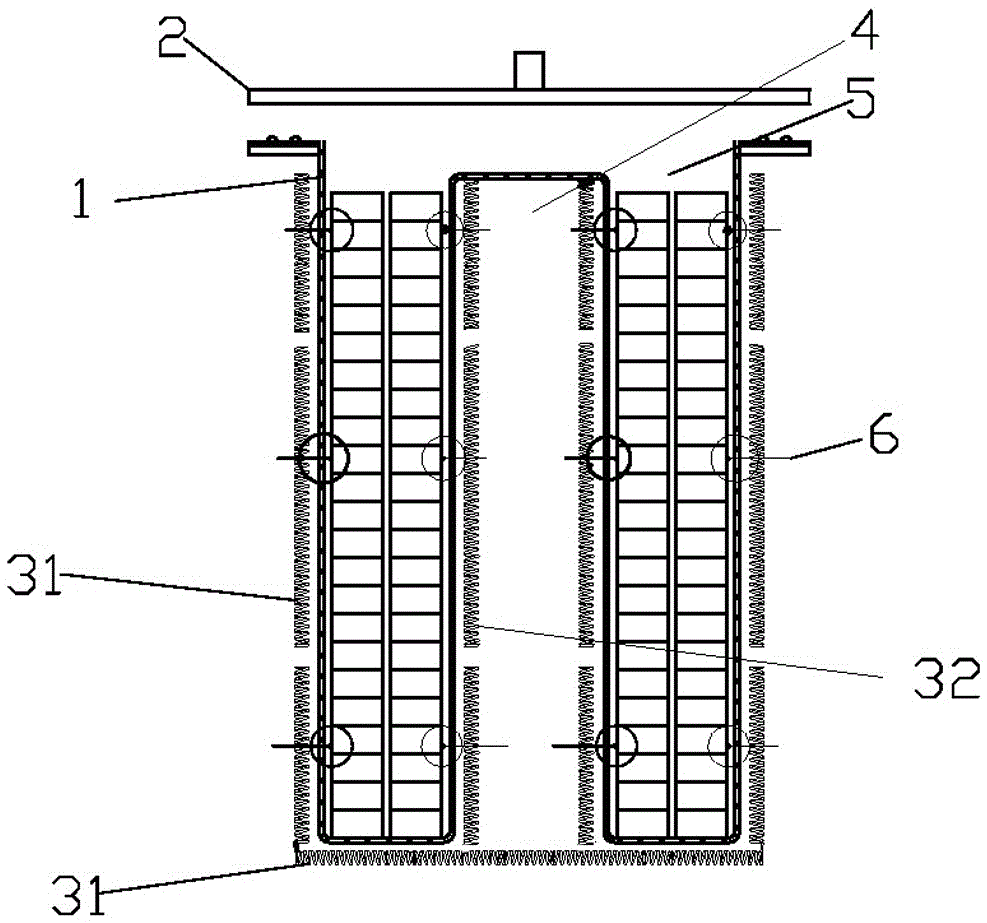

[0013] like Figure 1-3 As shown, a vacuum annealing furnace is composed of a furnace chamber 1, a furnace cover 2, a first heating element 31 and its temperature regulating device, a second heating element 32 and its temperature regulating device, and a barrel-shaped inner chamber 4. A sealing ring is provided between the furnace cover 2 and the furnace 1 to form a vacuum inner cavity in the furnace, and its vacuum degree can reach 1-0.001pa. The first heating element 31 is installed on the outer wall or inner wall of the furnace 1 and the outside of the bottom of the furnace 1. The furnace 1 is a barrel-shaped structure with an upward opening. , the opening of the barrel-shaped liner 4 is connected with a circular arc transition between the bottom middle of the furnace 1 to form an annular discharge area 5, and the inner cavity of the barrel-shaped liner 4 is fixedly installed with a se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com