Method for improving oil displacement efficiency of medium-permeability core

A technology of oil displacement efficiency and core, which is applied in the field of improving the oil displacement effect of medium-permeability cores, and can solve the problems of unclear pore throat production degree and remaining oil distribution range, and weak pertinence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

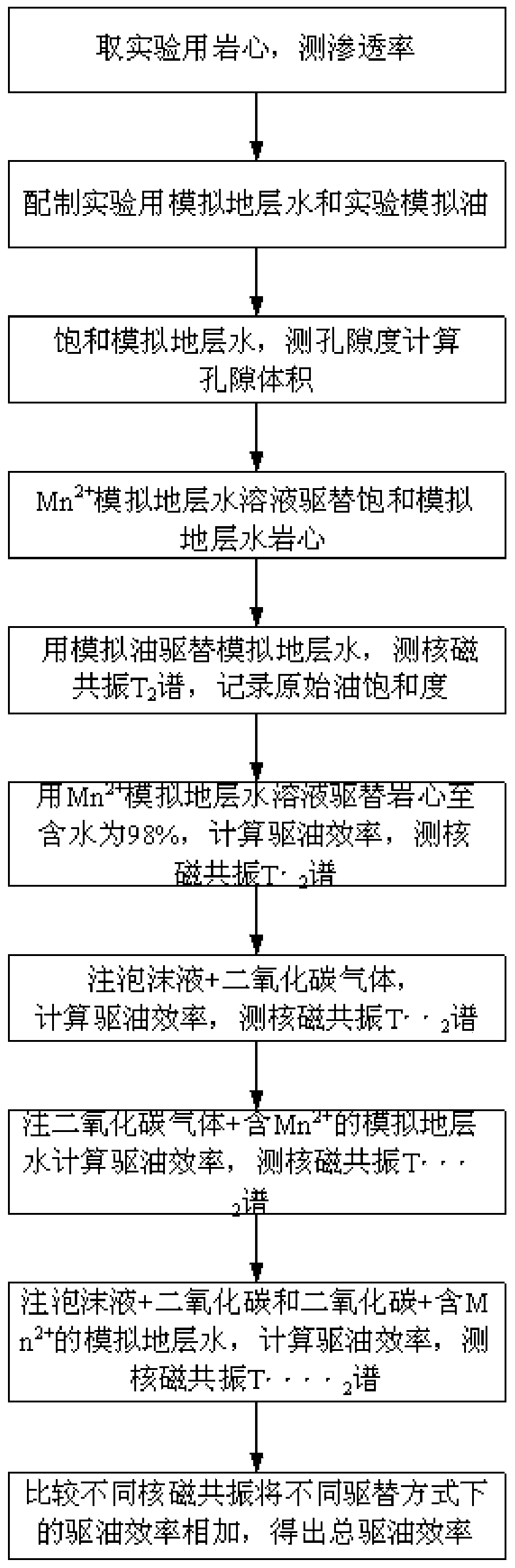

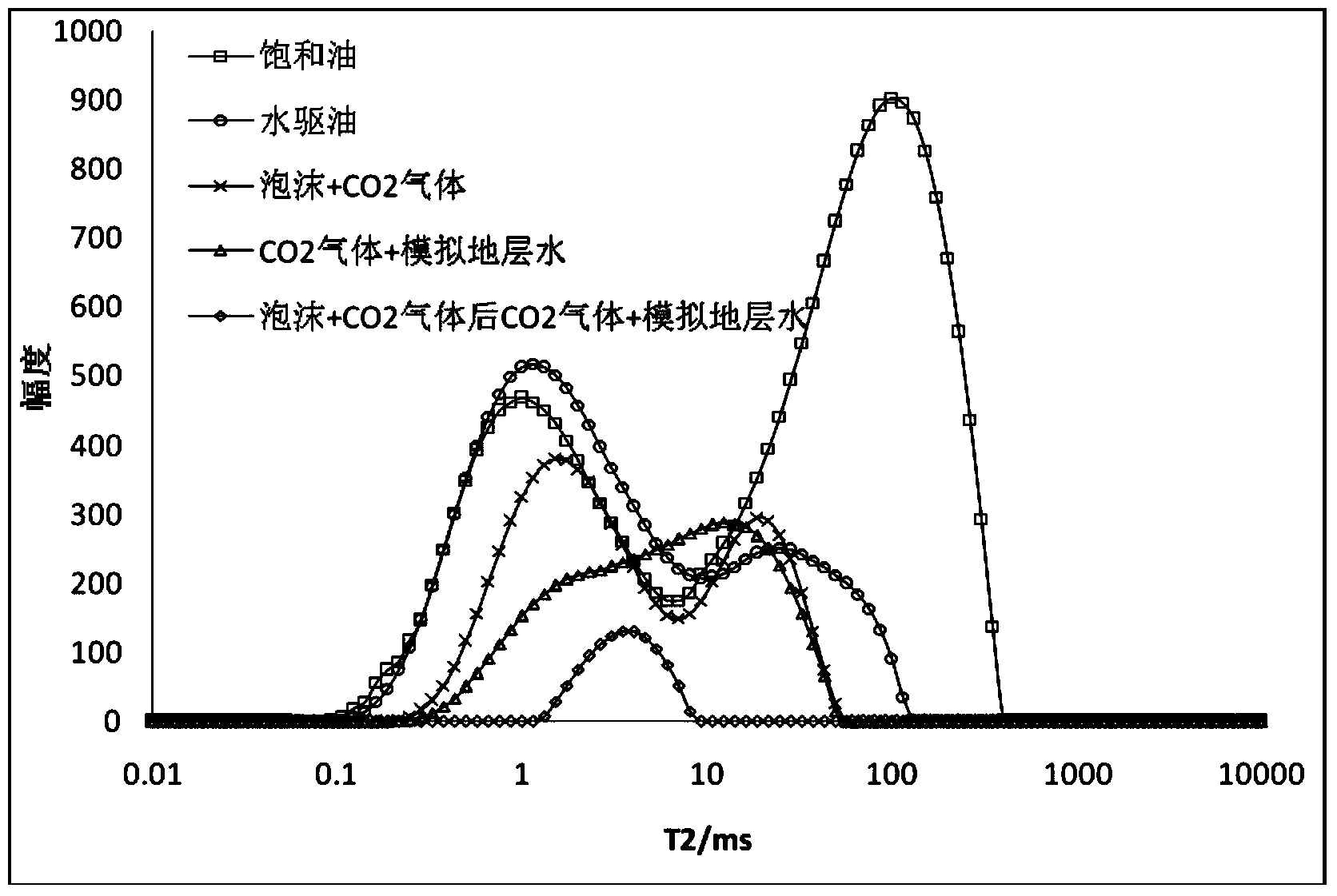

[0047] Such as figure 1 As shown, the method for improving the medium-permeability core oil displacement effect of the present invention comprises the following steps:

[0048] Step 1. Drill a core with a diameter of 2.5cm and a length of 6.064cm from the full-diameter core. After washing oil, the gas permeability of the core is 302×10 -3 μm 2 ;

[0049] Step 2, prepare simulated formation water, the salinity of formation water is 240000mg / L;

[0050] Step 3, prepare simulated crude oil, the viscosity reaches 1.82mPa.s;

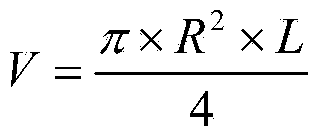

[0051] Step 4. Place the core in a high-pressure saturation device to saturate the core with simulated formation water. The measured porosity is 29.30%, and the pore volume is 8.43ml; the calculated pore volume is realized by the following formula:

[0052] V = π × R 2 × L 4

[00...

Embodiment 2

[0065] Steps 1 to 7 of the method for improving the oil displacement effect of medium-permeability cores are the same as in Example 1, except that in step 8, foam liquid + carbon dioxide gas is injected for 5 rounds, and in step 9, carbon dioxide gas + Mn-containing gas is injected 2+ 1 round of simulated formation water, inject foam liquid + carbon dioxide gas + carbon dioxide and Mn in step ten 2+ 5 rounds of simulated formation water.

Embodiment 3

[0067] Steps 1 to 7 of the method for improving the oil displacement effect of medium-permeability cores are the same as in Example 1, except that in step 8, foam liquid + carbon dioxide gas is injected for one round, and in step 9, carbon dioxide gas + Mn-containing gas is injected 2+ 8 rounds of simulated formation water, injecting foam liquid + carbon dioxide gas + carbon dioxide and Mn in step ten 2+ 1 round of simulated formation water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com