A drill pipe for directional expansion of coal seam crack scale and its application method

A drill pipe and coal seam technology, which is applied in the direction of drill pipe, drill pipe, drilling equipment, etc., can solve the problems of coal seam crack ductility uncontrollable, small crack size, uncontrollable direction, etc., to save manpower, increase depth, and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

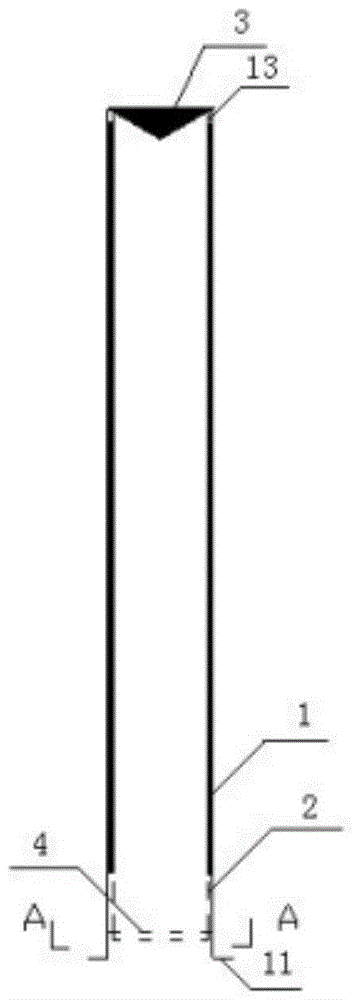

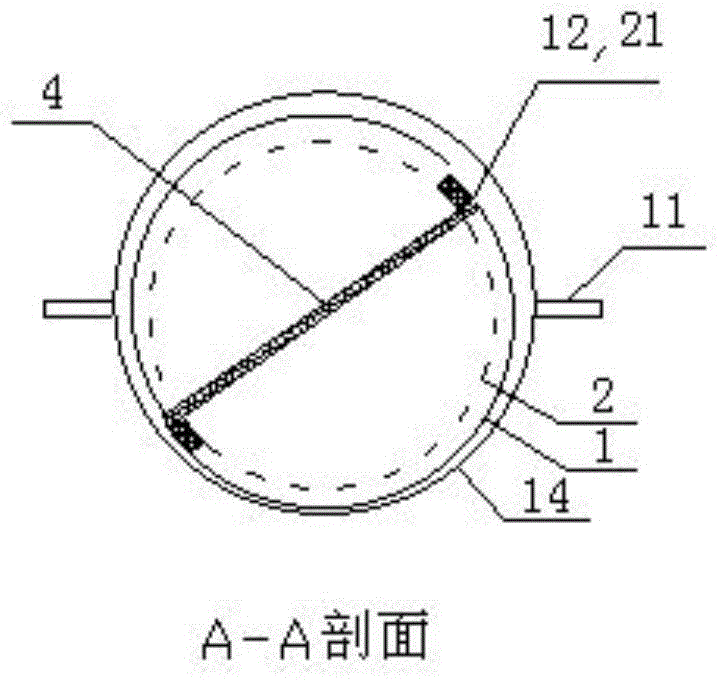

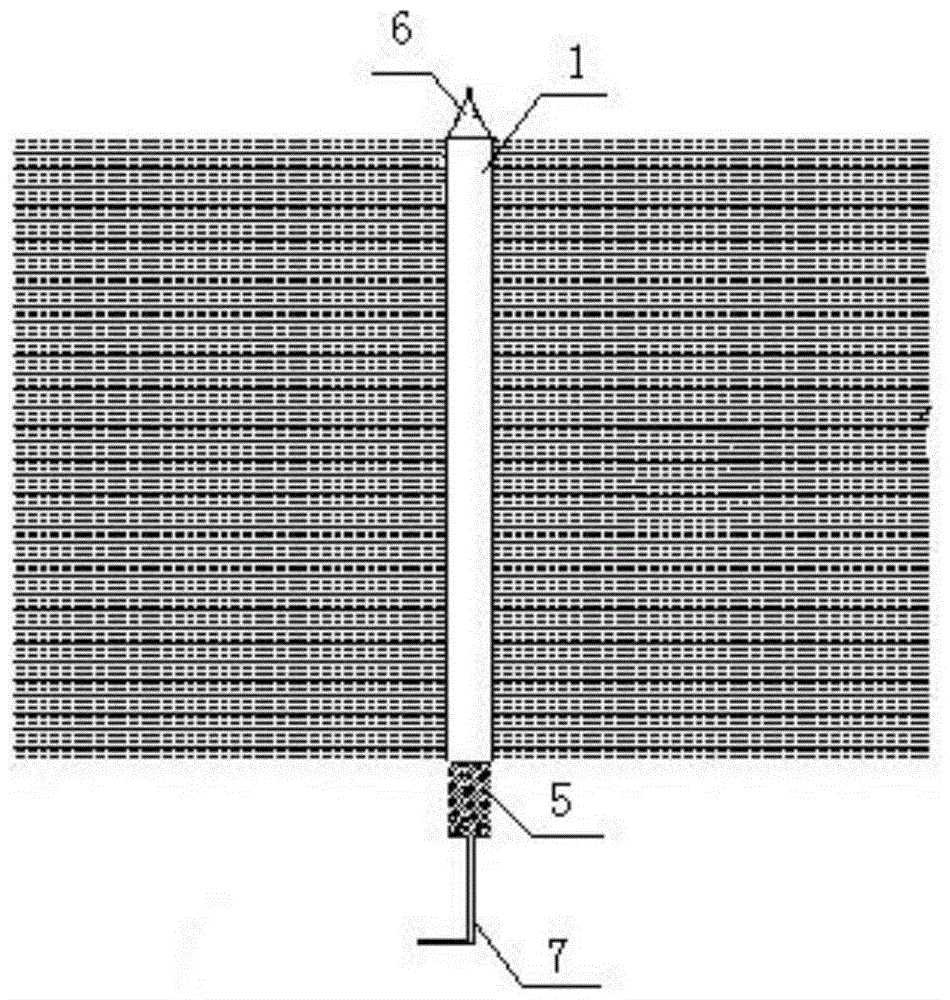

[0025] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0026] Such as figure 1 , figure 2 As shown, the present invention provides a drill pipe for directionally expanding the scale of coal seam cracks. The angle between them ranges from 0° to 90°. The handle 11 is inserted into the bottom of the outer sleeve through the iron ring 14, and the handle 11 is welded on the circumference of the iron ring 14. Generally, there are 1 or 2 handles 11. In actual production, according to the hardness of the coal seam, adjust the angle of the handle 11 to control the angle range of high-pressure water injection to the outer sleeve 1, thereby ensuring the water injection velocity and flow rate. A first water injection slit 12 is arranged on the bottom circumference of the outer casing 1, a water outlet hole 13 is arranged on the top of the outer casing, an inner casing 2 is arranged inside the outer casing, and a flow divider is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com