Blade of wind turbine

A technology of wind turbines and blades, which is applied to wind engines, wind engines consistent with the wind direction, engines, etc., to achieve the effect of high energy output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

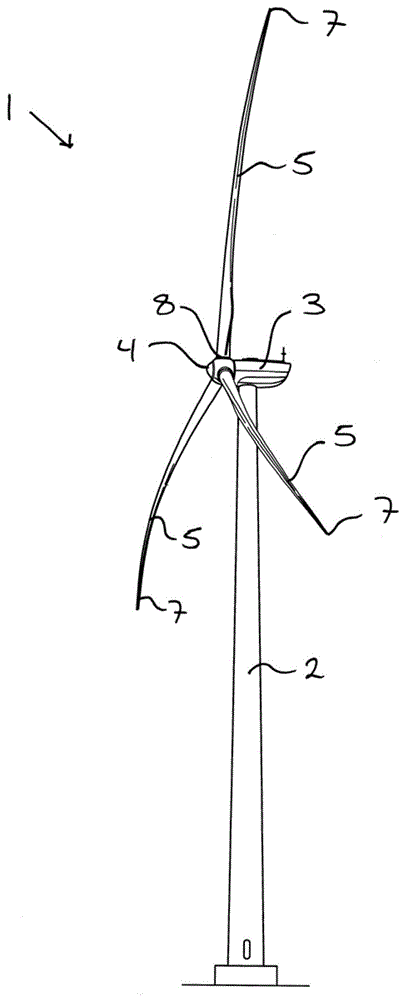

[0046] Depend on figure 1 It can be seen that the wind turbine 1 comprises a tower 2 and a nacelle 3 on top of said tower 2 . At one end of the nacelle 3, a hub 4 is provided on a main shaft not shown in the figure. Three wind turbine blades 5 are mounted on the hub 4 .

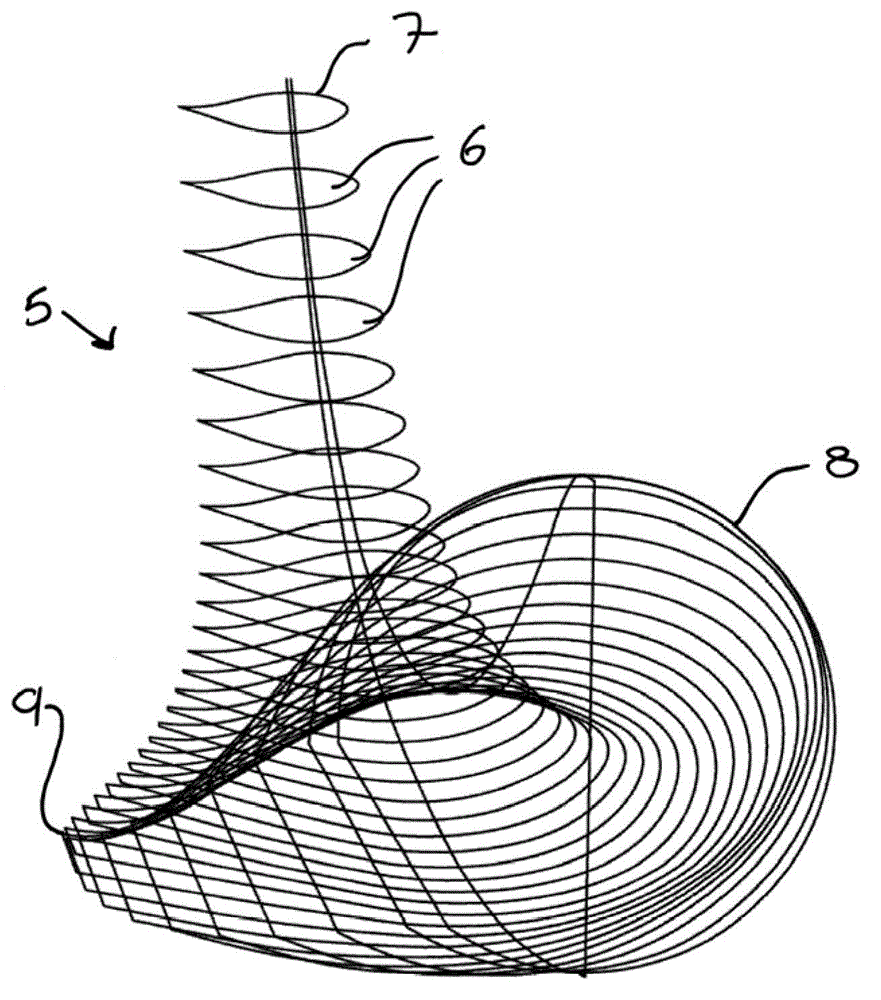

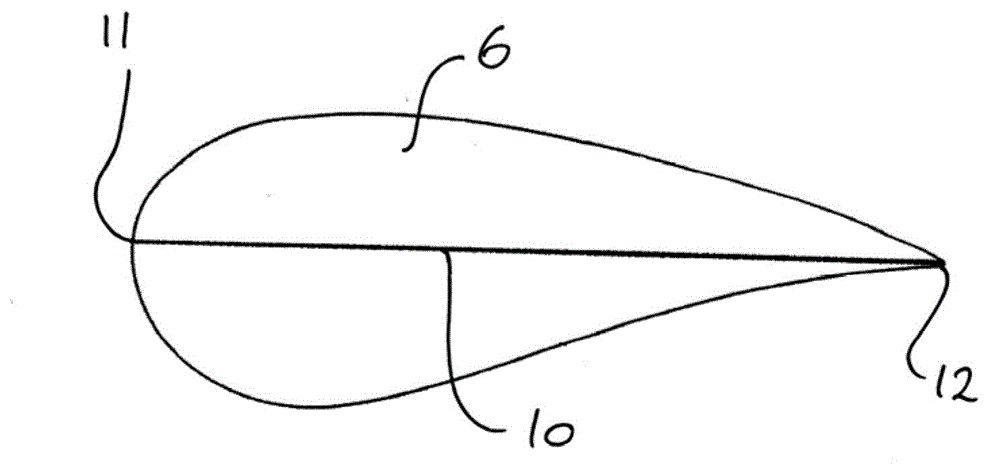

[0047] figure 2 The profile of a plurality of airfoil sections 6 of a wind turbine blade 5 is shown. figure 2 The wind turbine blades are curved in such a way that when the blade 5 is mounted, the blade tip 7 points away from the tower 2, towards the wind. Blades like this are also called curved or pre-curved wind turbine blades 5 .

[0048] For the purpose of illustration in this figure, the wind turbine blade 5 comprises several differently shaped sections or airfoils 6 .

[0049] figure 2 The blade 5 is shown looking from the root end 8 towards the blade tip (also called tip) 7 . At the root end 8, the profile is approximately circular and thick, and at some distance from the root end 8, the maxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com