Worm gear transmission type 360-degree dual-axis synchronous damping shaft

A technology of worm gear and damping shaft, which is applied in the direction of shaft and bearing, shaft, pivot connection, etc., can solve the problems of imperfect operation, cumbersome installation and disassembly operations, and limit the thin development of electronic equipment such as notebooks, etc., to achieve perfect connection and smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

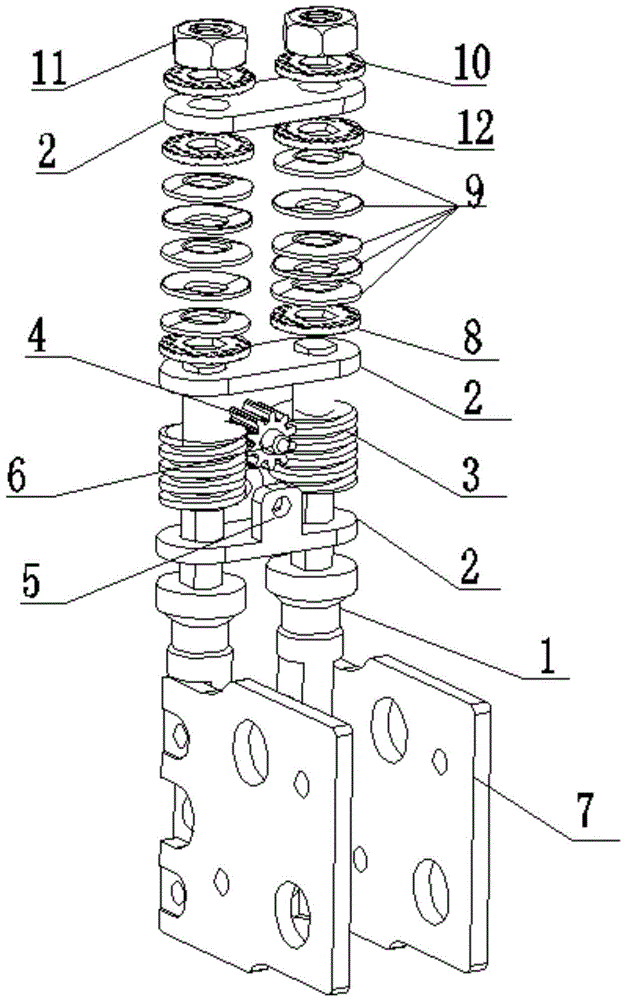

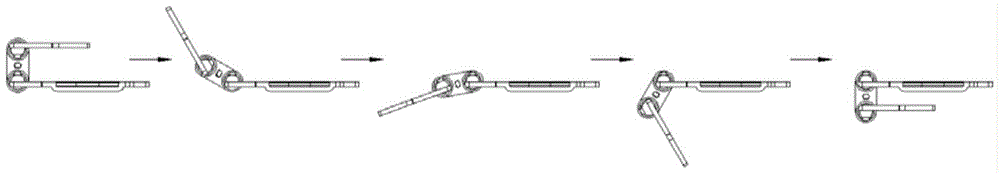

[0028] Such as figure 1 and figure 2 As shown, a worm gear and worm transmission type 360-degree dual-axis synchronous damping shaft includes two shaft cores 1 and at least two connecting plates 2, and a first worm 3 is respectively provided on the two shaft cores, corresponding to two The first worm is provided with a first worm gear 4; each first worm is fixed on the corresponding shaft core, wherein two connecting plates are positioned at the two ends of the two first worms, and are sleeved on the On the two shaft cores, the two shaft cores are radially separated by a set distance, and the two shaft cores can axially stop and rotate freely in the circumferential direction relative to the two connecting plates; the first The worm gear is positioned in the accommodation space surrounded by the two connecting plates and the two first worms, and the radially opposite sides of the first worm gear mesh with the two first worms respectively. In this way, the two independent sha...

Embodiment 2

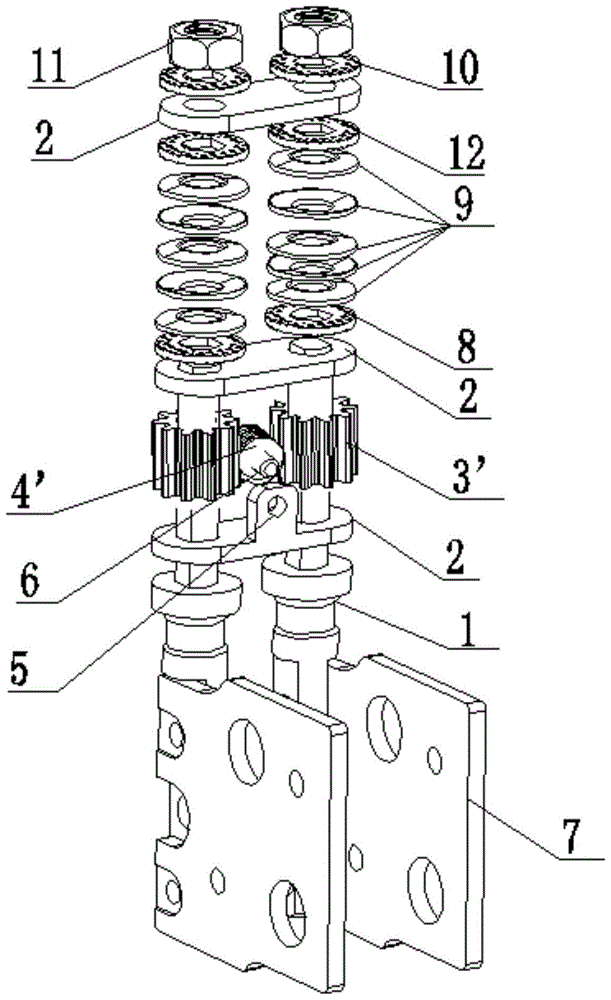

[0034] Such as image 3 and Figure 4 As shown, a worm gear and worm transmission type 360-degree dual-axis synchronous damping shaft includes two shaft cores 1 and at least two connecting plates 2, and a second worm wheel 3' is respectively provided on the two shaft cores, corresponding to two shaft cores. Each of the second worm wheels is provided with a second worm 4'; each second worm wheel is sleeved on the corresponding shaft core, wherein two connecting plates are positioned at the two ends of the two second worm wheels, and are sleeved It is arranged on the two shaft cores, so that the two shaft cores are radially separated by a set distance, and the two shaft cores can axially stop and rotate freely in the circumferential direction relative to the two connecting plates; The second worm is positioned in the accommodation space surrounded by the two connecting plates and the two second worm gears, and the radially opposite sides of the second worm are meshed with the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com