Sunlight greenhouse

A technology of solar greenhouse and gable wall, applied in the field of solar greenhouse, can solve the problems of poor heat storage and thermal insulation capacity, poor thermal insulation and low strength of the north wall structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

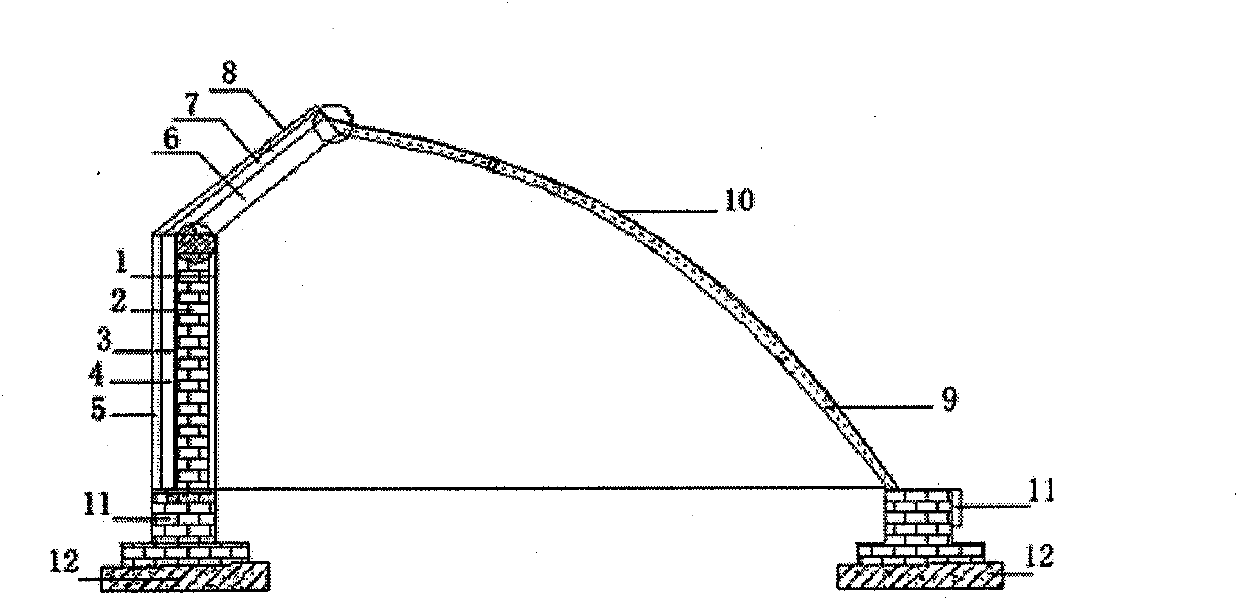

[0070] Embodiment 1: The solar greenhouse includes a north wall structure, an east gable, a west gable, a back slope structure and a front slope structure; the north wall structure includes a protective layer (1), a heat storage layer (2), Moisture barrier layer (3), heat insulation layer (4) and first waterproof layer (5); the back slope structure includes structural board (6), concrete layer (7) and second waterproof layer (8) from inside to outside ); the front house structure is made of an arch (9) and a drip-free film (10); wherein the north wall structure, the east side gable, the west side gable and the front slope structure all pass through the moisture-proof layer (11), the concrete cushion ( 12) Connect to ground.

Embodiment 2

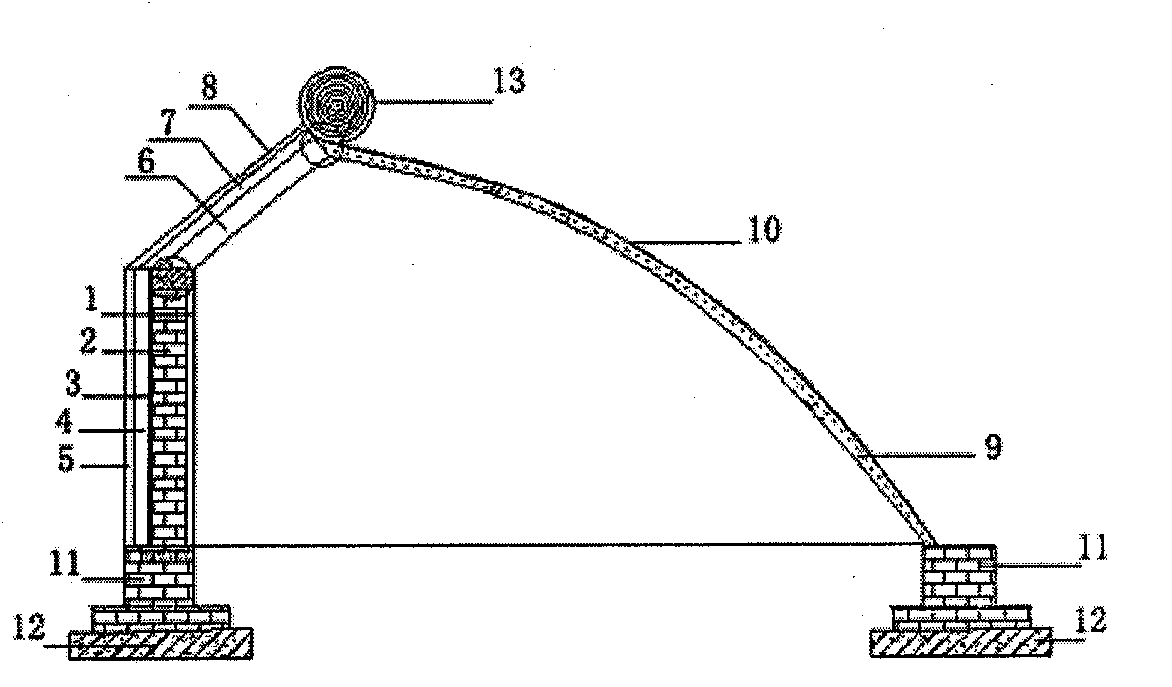

[0071] Embodiment 2: The solar greenhouse includes a north wall structure, an east gable, a west gable, a back slope structure and a front slope structure; the north wall structure sequentially includes a protective layer (1), a heat storage layer (2), Moisture barrier layer (3), heat insulation layer (4) and first waterproof layer (5); the back slope structure includes structural board (6), concrete layer (7) and second waterproof layer (8) from inside to outside ); the front house structure is made of an arch (9) and a drip-free film (10); wherein the north wall structure, the east side gable, the west side gable and the front slope structure all pass through the moisture-proof layer (11), the concrete cushion ( 12) Connect to ground. And on the non-drip film (10) surface of front room structure, be covered with heat preservation quilt (13), it can be used for keeping warm at night.

[0072] Comparing Example 1 and Example 2, the nighttime heat preservation capacity of Exam...

Embodiment 3

[0073] Embodiment 3: The solar greenhouse includes a north wall structure, an east gable, a west gable, a back slope structure and a front slope structure; the north wall structure includes a protective layer (1), a thermal storage layer (2), Moisture barrier layer (3), heat insulation layer (4) and first waterproof layer (5); the back slope structure includes structural board (6), concrete layer (7) and second waterproof layer (8) from inside to outside ); the front house structure is made of an arch (9) and a drip-free film (10); wherein the north wall structure, the east side gable, the west side gable and the front slope structure all pass through the moisture-proof layer (11), the concrete cushion ( 12) Connect to ground. In the north wall structure, the thickness of the protective layer is 20mm-30mm, the thickness of the heat storage layer is 350mm-400mm, the thickness of the moisture barrier layer is 0.5mm-5mm, the thickness of the heat insulation layer is 80mm-150mm, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com