Building-block detecting tool special for detecting longitudinal beam assembly on bottom side of vehicle

A longitudinal beam assembly, building block technology, applied in the direction of measuring devices, mechanical devices, mechanical measuring devices, etc., can solve the problems of reducing the service life of the inspection tool, large stress, affecting the detection accuracy, etc., and achieves easy opening and closing. The effect of improving service life and improving detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see Figure 1-14 :

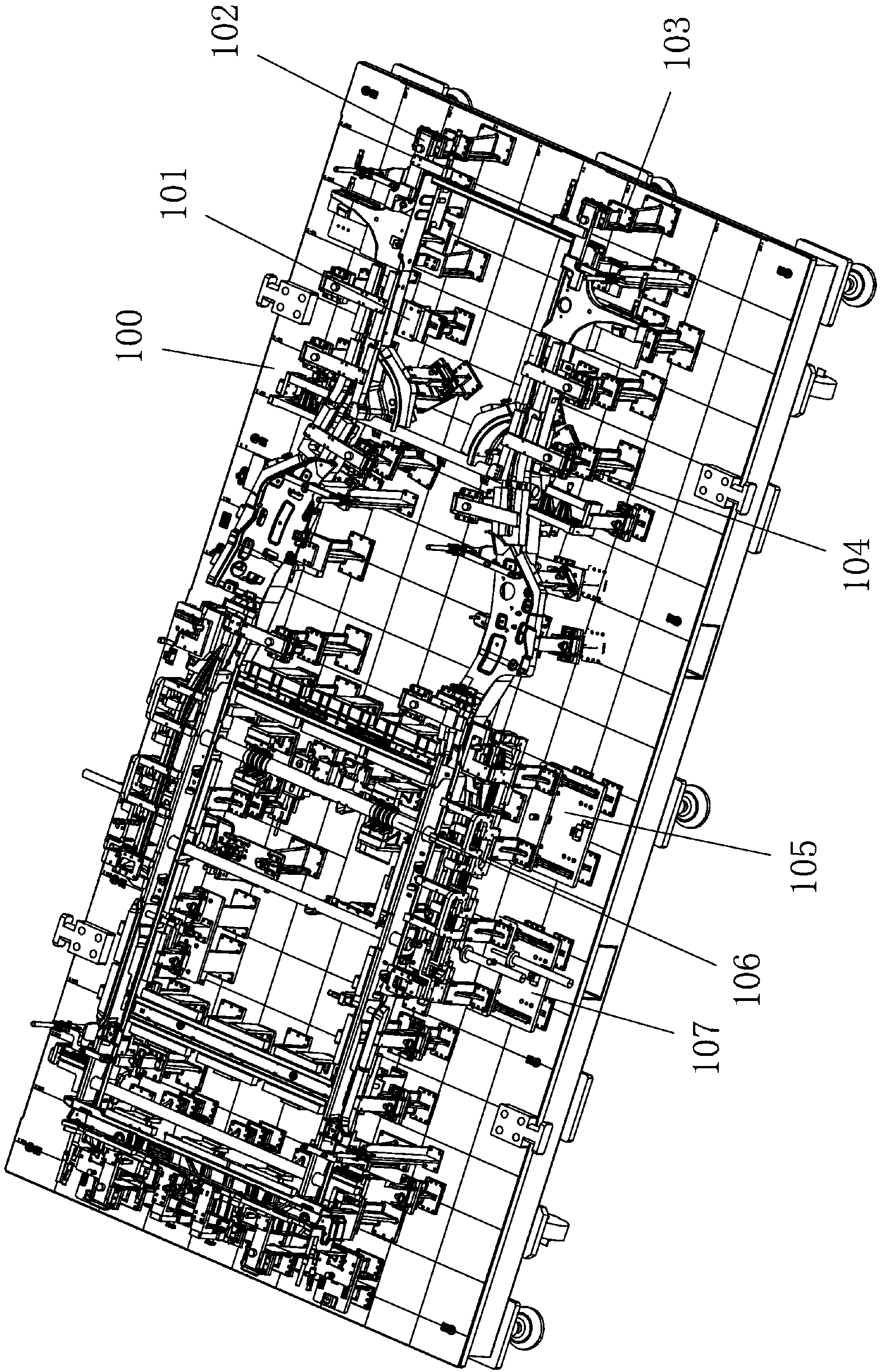

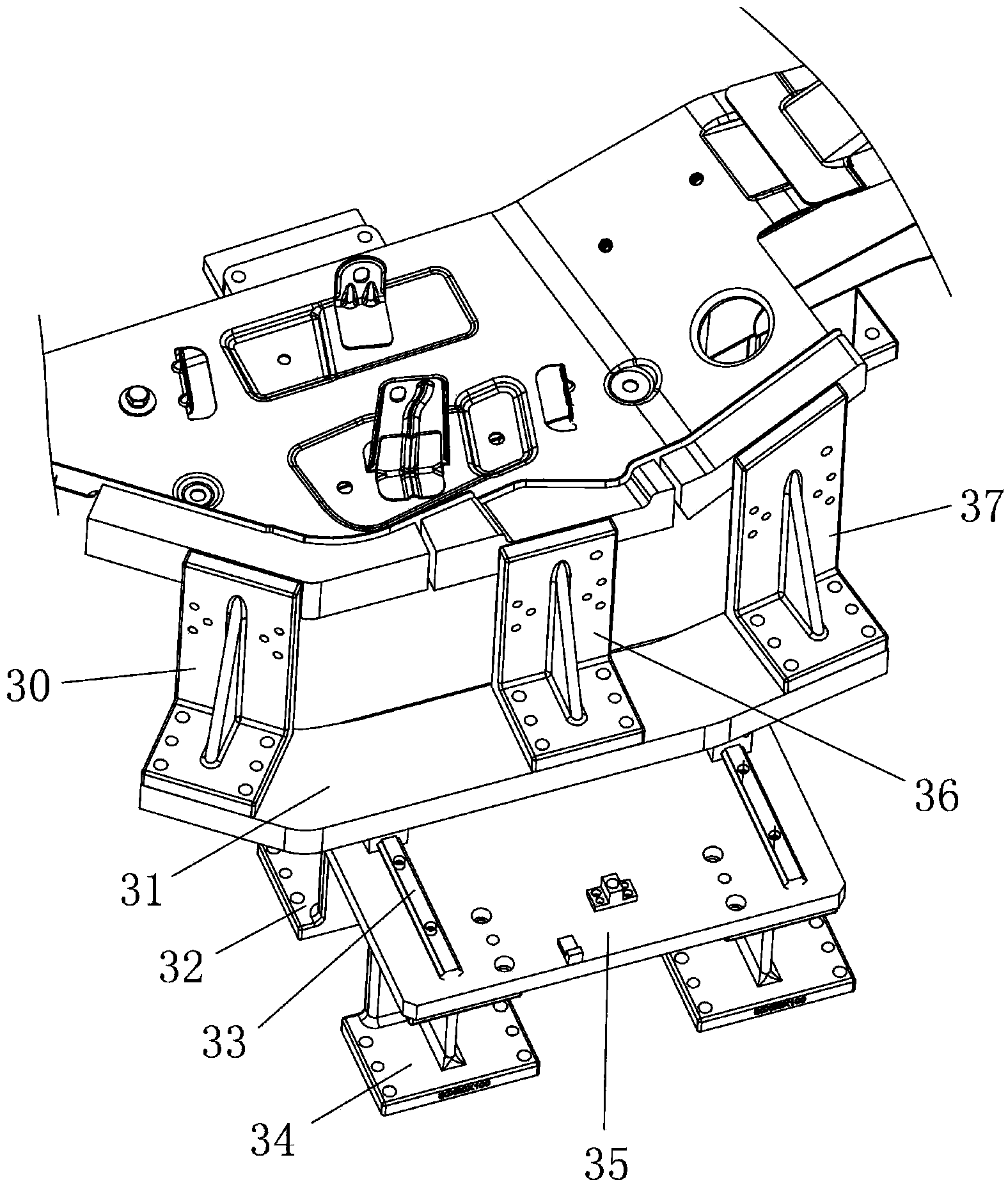

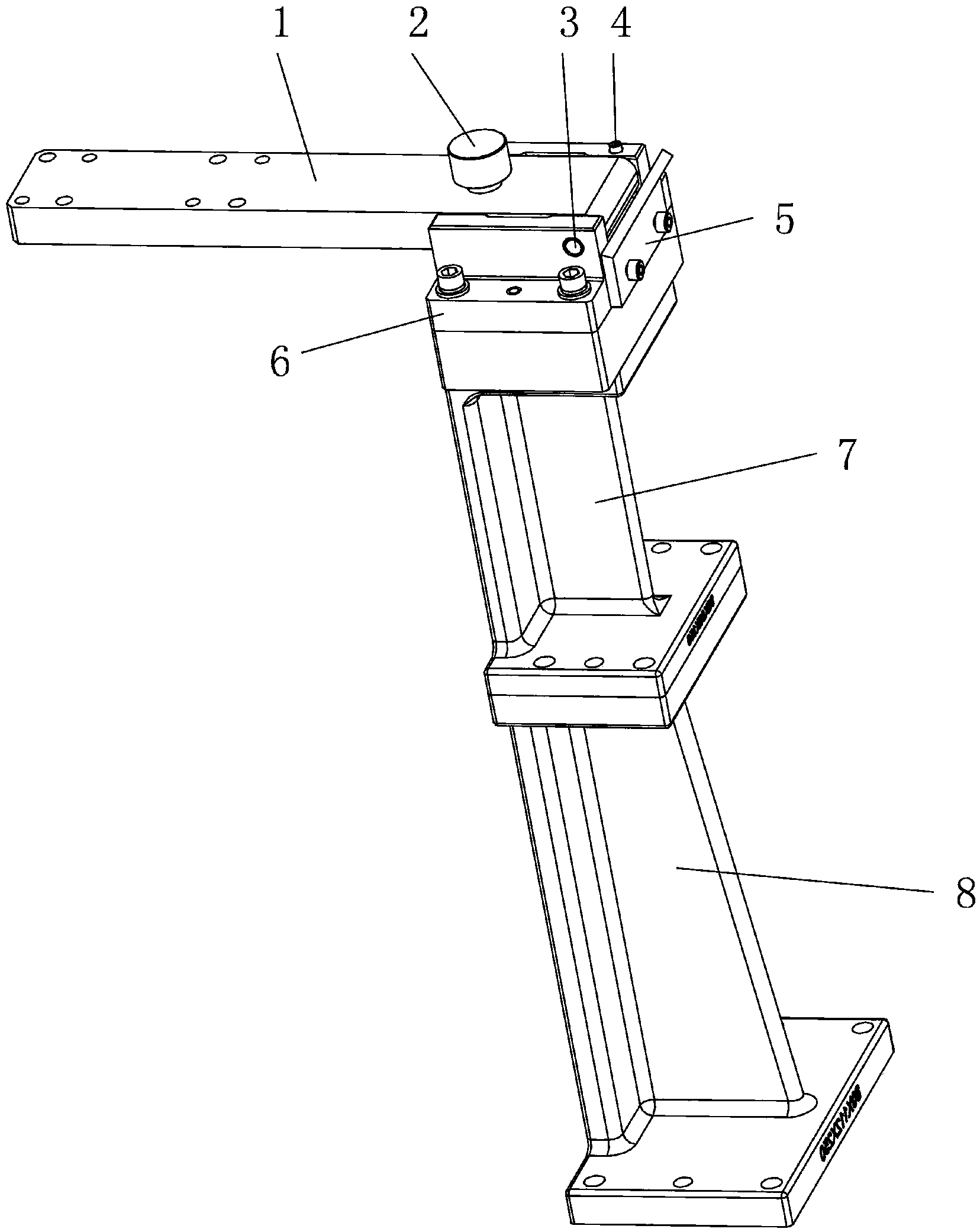

[0047] A building block structure checker specially used for testing vehicle bottom side longitudinal beam assemblies, including a base 100, on which several support mechanisms for supporting the assembly to be tested are arranged, and several support mechanisms are used for A positioning mechanism for locating the assembly to be tested, a number of hole position detection mechanisms, a number of non-going gauges for detecting surface contours, and a number of flushing gauges for detecting edge contours, the non-going gauges and flushing gauges pass through corresponding The flap mechanism or slide rail mechanism is installed on the base,

[0048] Wherein, the first embodiment of the turnover mechanism: the I-type bracket assembly is fixedly installed on the base 100, the upper part of the I-type bracket assembly is fixed with 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com