Device and method for testing porosity and adsorption parameters of gas-bearing shale

A technology for shale porosity and adsorption parameters, which is applied in measuring devices, suspension and porous material analysis, instruments, etc. It can solve the problems of adsorption gas volume error, unstable gas injection pressure, and failure to consider the heating and constant temperature of injected gas, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

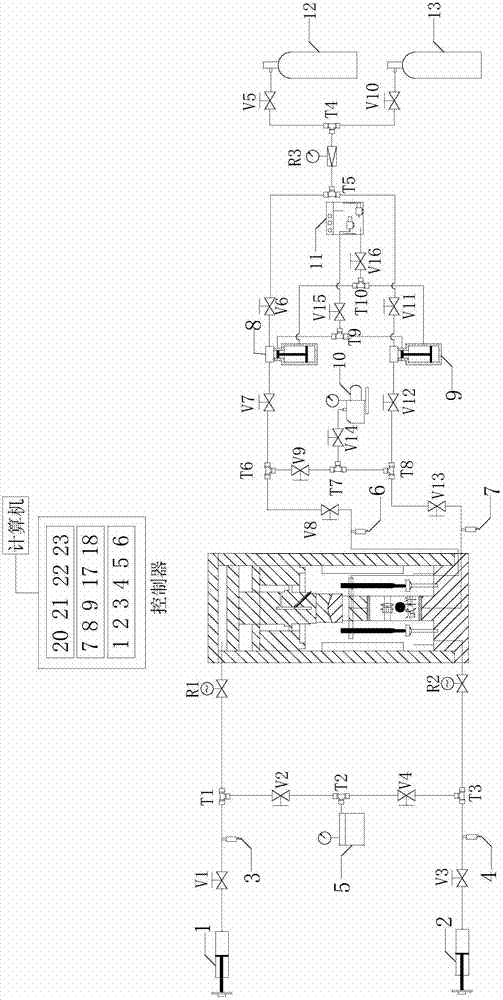

[0096] like figure 1 As shown, the testing device for gas-bearing shale porosity and adsorption parameters of the present invention includes a constant temperature triaxial pressure chamber, an axial pressure loading system, a confining pressure loading system, an upper end adsorption system, a lower end adsorption system, a vacuum system, a constant temperature system and Data control acquisition system;

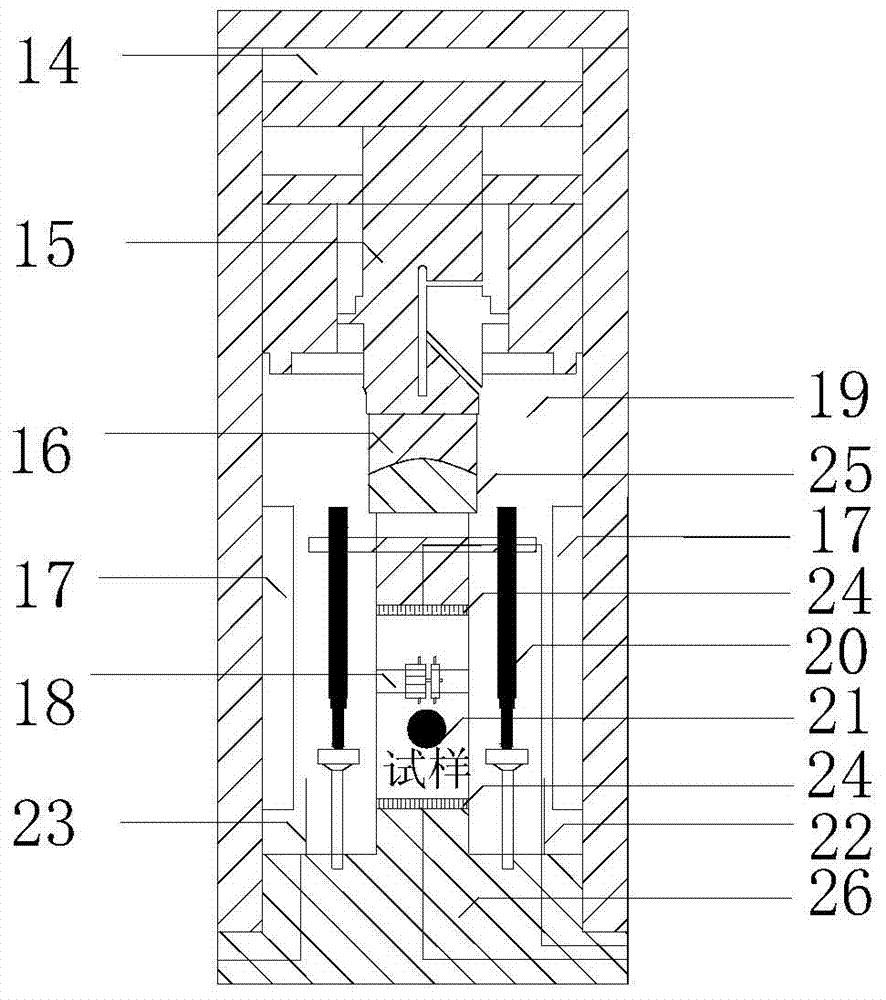

[0097]The constant temperature triaxial pressure chamber includes an axial pressure chamber 14, a confining pressure chamber 19, a self-balancing piston 15, a ball head 16, a pressure-elastic axial displacement sensor 20, a chain-type annular displacement sensor 18, two sets of upper and lower porous gaskets 24, The upper pressure head 25, the lower pressure bearing table 26 and the sample heating device; the axial pressure chamber 14 is arranged above the confining pressure chamber 19, and is connected by the self-balancing piston 15, and the self-balancing piston 15 exten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com