Method for controlling RFID full-automatic coding product inspection device

A control method and fully automatic technology, which is applied to record carriers, instruments, computer components, etc. used by machines, and can solve problems such as increased label scrapping rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

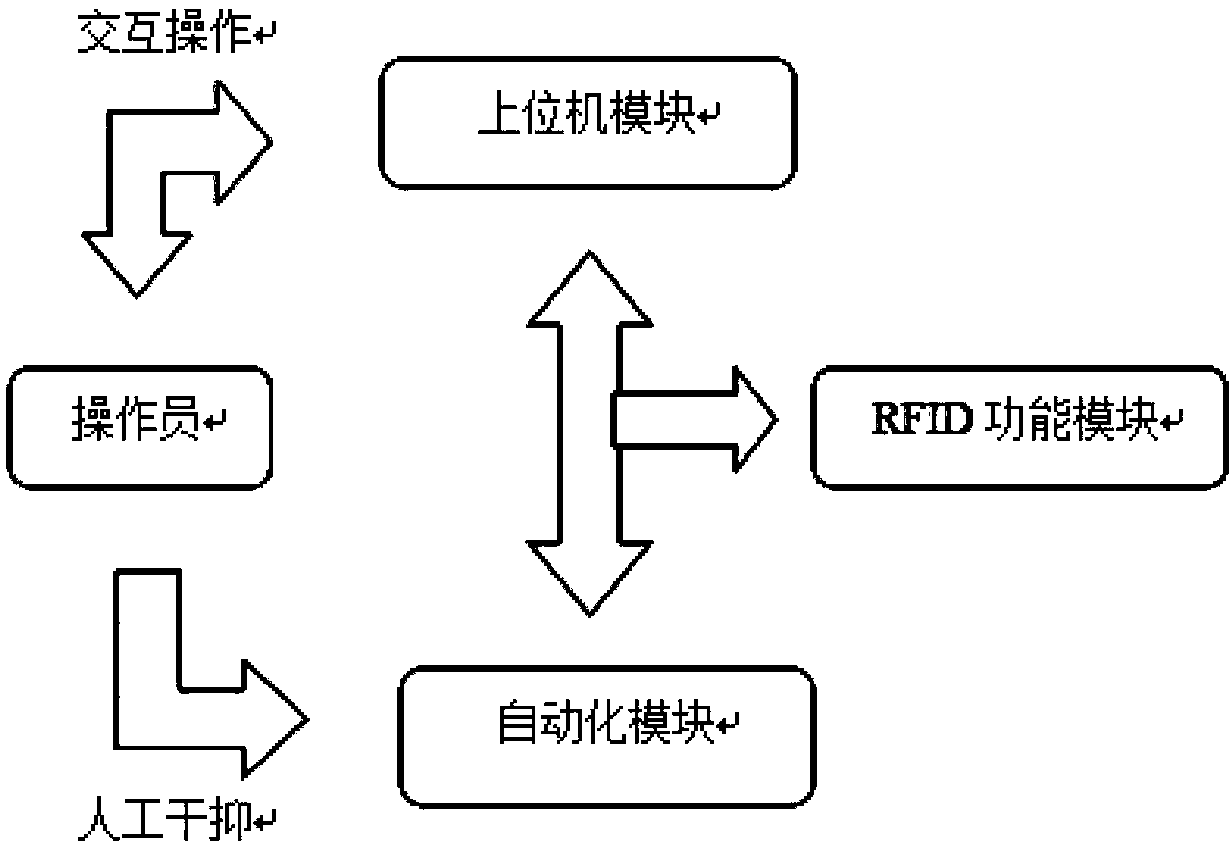

[0023] like figure 2 As shown, the RFID automatic coding quality inspection equipment of the present invention mainly includes an automation module, an RFID function module, and a host computer module. After positioning, the current electronic label is inspected or encoded through the RFID function module, and then a complete operation cycle of the data log is generated. The main function of this RFID automatic coding quality inspection equipment is to carry out personalized coding and personalized quality inspection of RFID electronic tags of HF, UHF, LF and other types, and at the same time, the coding Or the RFID electronic label products for quality inspection are automatically classified and sorted, and the associated log data is generated, which can be used for cloud data call in the IoT application subsystem or as a data reference.

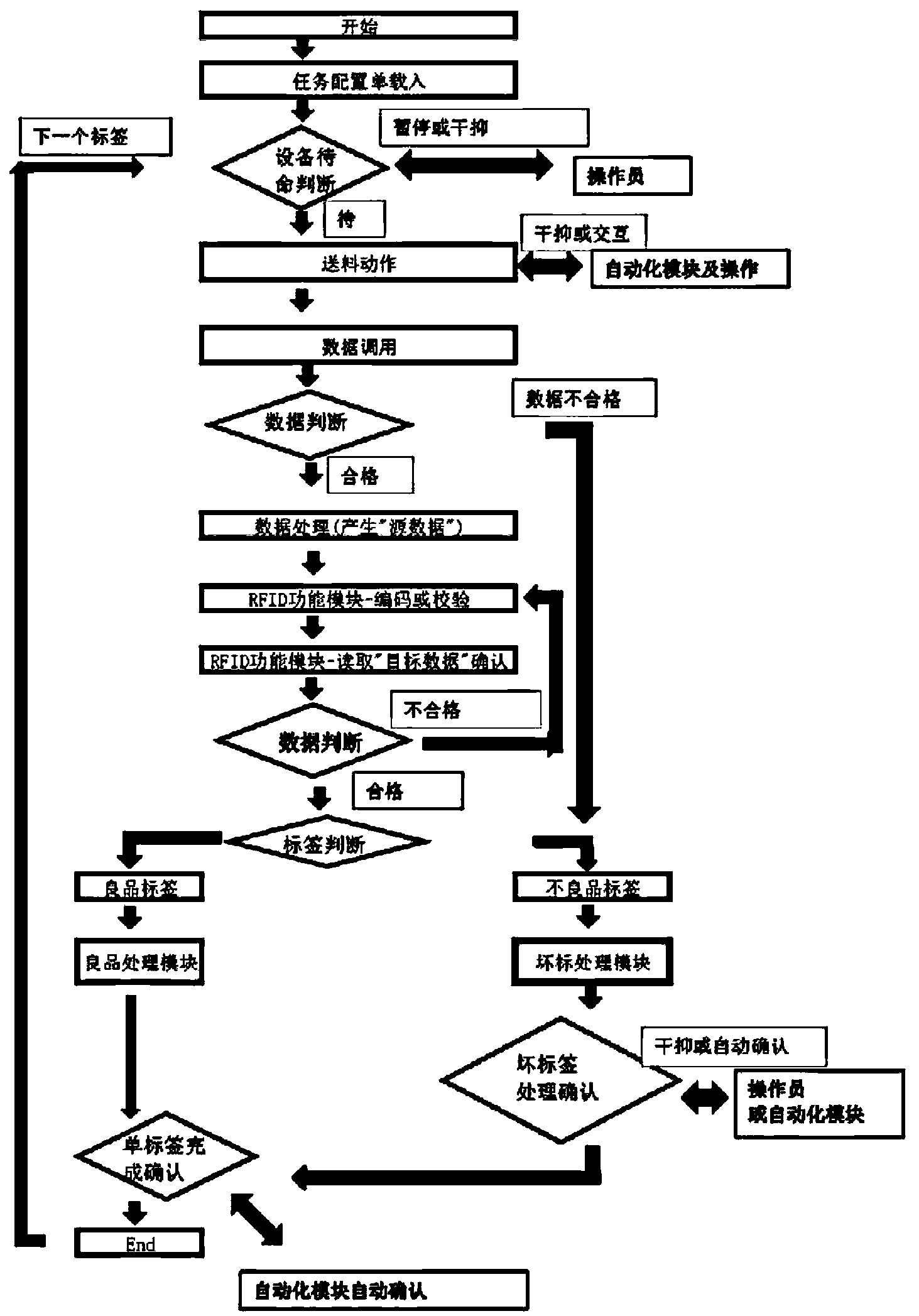

[0024] like figure 1 As shown in the present invention, a control method for an RFID automatic coding quality inspection equipment incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com