Linear ultrasonic motor clamping positioning device with one end supported in hinged mode

A linear ultrasonic motor, clamping and positioning technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve problems such as large tangential stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

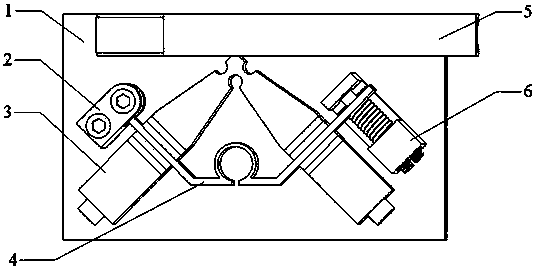

[0023] The utility model relates to a linear ultrasonic motor clamping and positioning device hinged at one end, which belongs to the technical field of ultrasonic motors. Such as figure 1 As shown, the device is composed of a base 1 , a V-shaped stator 3 , a mover 5 , and clamping components, wherein the clamping components include: a rotating device 2 , a support 4 and a pre-pressure applying device 6 .

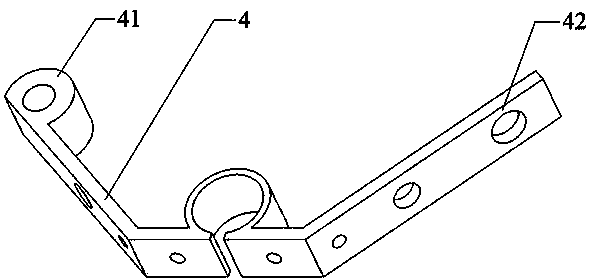

[0024] This new type of clamping and positioning device, such as figure 1 As shown, there is only one degree of freedom for rotation centered on the head end 41 of the support member, and the prepressure loading of the stator 3 on the mover 5 is realized by applying pressure to the force end 42 of the support member by the preload applying device 6 .

[0025] This clamping and positioning device for a linear ultrasonic motor hinged at one end is used for clamping and positioning a V-shaped stator. The V-shaped stator has two vibrators, and each vibrator consists of a front...

Embodiment 2

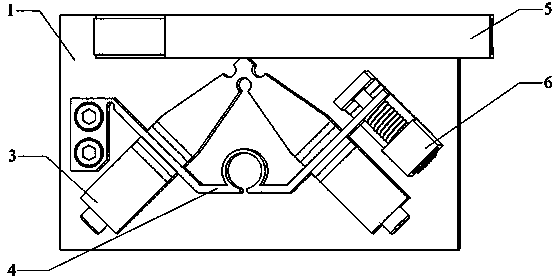

[0031] The invention relates to a clamping and positioning device of a linear ultrasonic motor with a flexible hinge at one end, which belongs to the technical field of ultrasonic motors. Such as figure 2 As shown, the device is composed of a base 1 , a stator 3 , a mover 5 , and clamping components 4 and 6 , wherein the clamping components include: a support 4 and a pre-pressure applying device 6 .

[0032] This new type of clamping and positioning device, such as figure 2 As shown, the position centered on the head end 41 of the support is fixed, and the pressure is applied to the force end 42 of the support by the pre-pressure applying device 6, and the flexible hinge 43 of the support is pushed to deform on the plane where the stator is located to realize the stator 3 pairs. Preloading of mover 5.

[0033] This clamping and positioning device of a linear ultrasonic motor with a flexible hinge at one end is used for clamping and positioning a V-shaped stator. The V-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com