Reciprocating seal experiment table for measuring friction feature of single seal ring

A sealing ring and friction technology, applied in the field of reciprocating sealing test benches, can solve the problems of no friction distinction, difficulty in simulating aviation actuator application conditions, and inability to realize high pressure and high speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

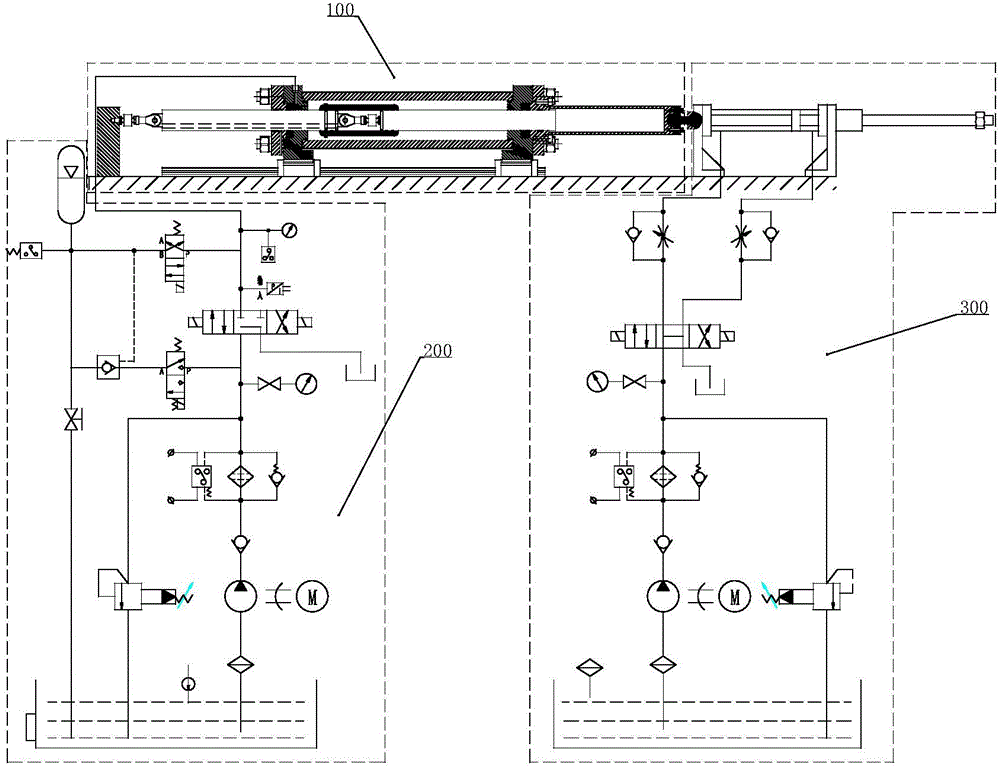

[0024] Such as figure 1 As shown, the present invention is a reciprocating seal test bench for measuring the friction characteristics of a single sealing ring, which consists of three parts: an experimental cylinder 100, a high-pressure simulation system 200 connected to the experimental cylinder 100, a high-speed drive cylinder and its hydraulic system 300.

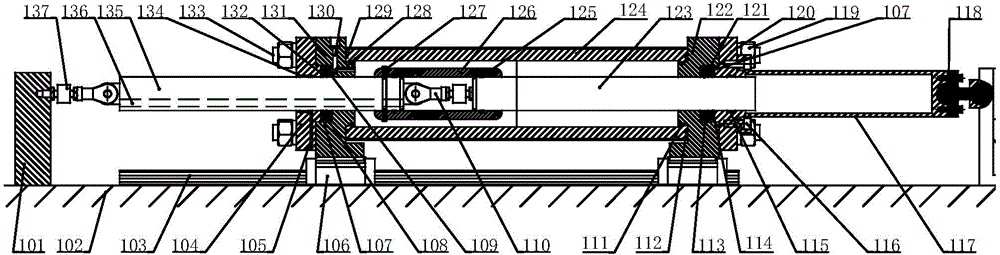

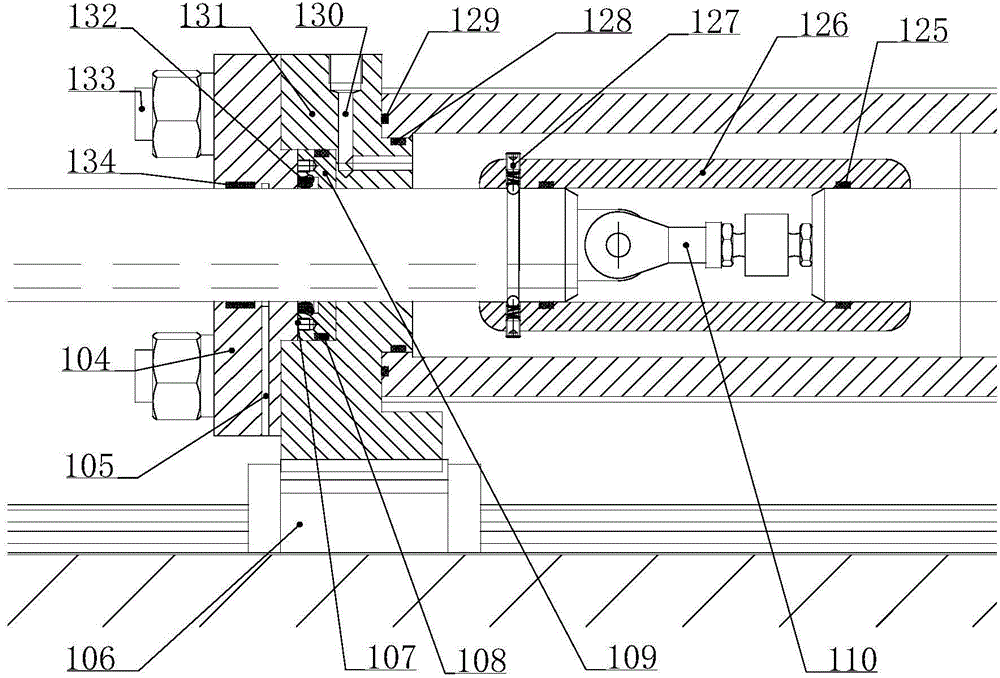

[0025] Such as figure 2 , image 3 and Figure 4As shown, the experimental cylinder 100 includes a workbench 102, a mounting base 101 fixed at one end of the workbench 102, a linear guide rail 103 fixed on the workbench 102, two slide blocks 106 installed on the linear guide rail 103, two The left cylinder base 131 and the right cylinder base 122 are installed respectively on the slide block 106, and the cylinder barrel 124 is installed between the left cylinder base 131 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com