Anti-sticking and diagnostic strategy for exhaust system valves

An exhaust system, waste gate valve technology, applied in electrical control, combustion engine, machine/engine, etc., to solve problems such as turbocharger or engine failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

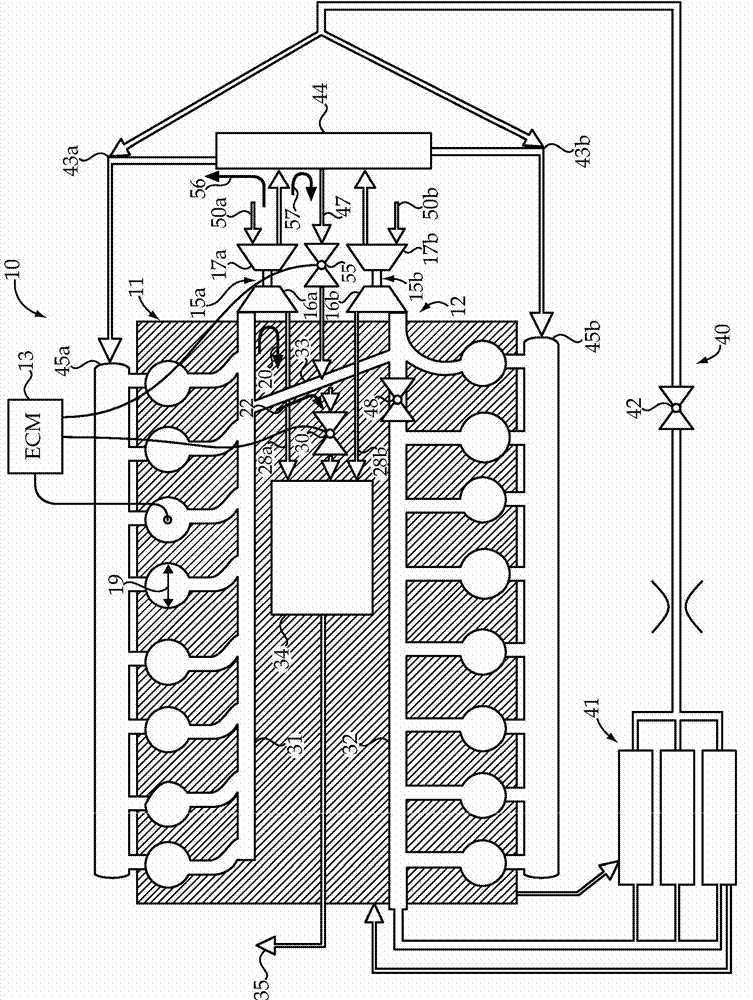

[0008] see figure 1 , shows an exemplary engine system 10 according to the present invention. Engine system 10 includes an electronically controlled engine 11 fluidly connected to an exhaust system 12 . In the illustrated embodiment, the engine 11 is a sixteen cylinder large bore compression ignition engine, the operation of which is controlled by an electronic controller 13 . One aspect of engine control is the operation of electronically controlled fuel injectors (not shown) associated with each of the individual large bore cylinders 19, which may have a bore size in excess of 140 millimeters. Also, in the illustrated embodiment, the electronically controlled engine 11 has a V-configuration with two separate banks of eight engine cylinders each. Thus, the engine 11 has a first exhaust manifold 31 and a second exhaust manifold 32, which may be considered part of the exhaust system 12, which exhausts The tailpipe 35 terminates. Although not required, equalization duct 33 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com