Manual emptying device of harvester

A technology of feeding device and harvester, which is applied in the direction of harvesters, cutters, agricultural machinery and implements, etc. It can solve the problems of grain jamming, inability to disassemble, troublesome maintenance, etc., to achieve convenient disassembly and maintenance, convenient disassembly, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

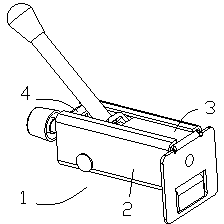

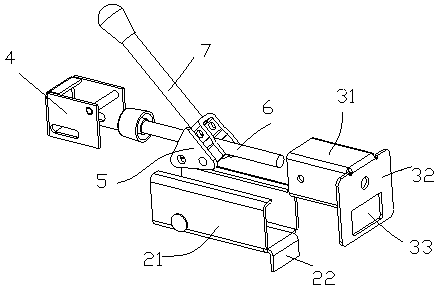

[0016] Such as Figure 1 to Figure 2 As shown, the manual feeding device 1 of the harvester of the present invention includes a main housing 2, the head of the main housing 2 is provided with a detachable first sub-housing 3, and the tail of the main housing 2 is provided with a The second sub-housing 4 is detachable. The main housing 2 is provided with a triangular driving seat 5 on which a horizontally arranged driving bar 6 and an obliquely arranged manual lever 7 are arranged.

[0017] The main housing 2 includes a half-open first body 21 , the head of the first body 21 is provided with a downwardly turned engagement tab 22 , and the first su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com