Gracilaria lemaneiformis-containing forage for lutianus stellatus Akazaki and preparation method thereof

A technology of spot snapper and feed, which is applied in the field of spot snapper feed and its preparation, can solve the problems that the research on asparagus feed is still scarce, and achieve the effects of good food attraction, comprehensive nutrition, and reduced usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

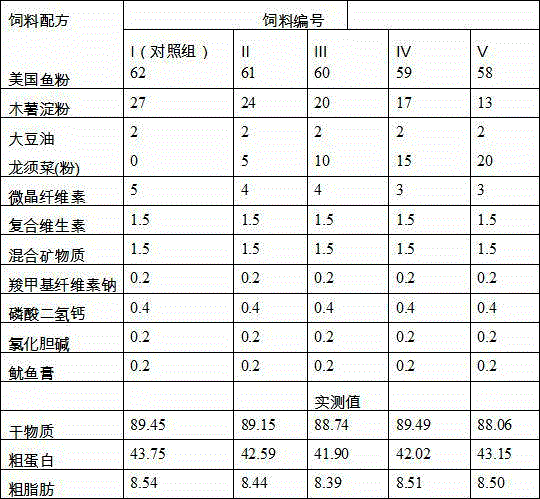

[0025] In order to detect the most suitable addition amount of Asparagus, we use 0 (control), 5%, 10%, 15%, and 20% dry powder of Asparagus to replace fish meal or other vegetable protein sources to make star snapper. The feed and feed formula are shown in Table 1 (the values are percentages by weight), and the preparation steps are as follows:

[0026] ① Collect fresh asparagus, clean it, remove impurities, and dehydrate it with a centrifugal dehydrator. The speed of the centrifugal dehydrator is 3000-5000 rpm, and the centrifuge is dehydrated for 3-10 minutes.

[0027] ②Preparation of asparagus powder: Put the dehydrated asparagus in a drying box for drying, the drying temperature is set to 70~85℃, the drying time is set to 4 to 5 hours, and the moisture content of the dried asparagus is controlled. Between 10% and 15%, then use a pulverizer to pulverize to 80-120 meshes for use.

[0028] ③Mixing: According to the feed formula shown in Table 1, the lump protein source materials ...

Embodiment 2

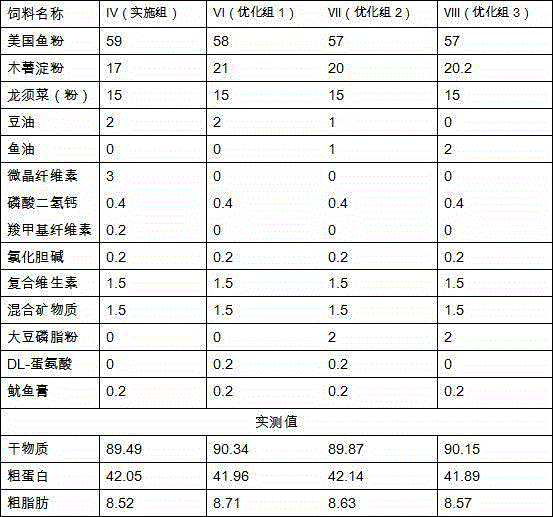

[0033] In order to obtain the best feed formula for Asparagus stellate snapper, the ratio of raw materials and auxiliary materials was adjusted on the basis of 15% Asparagus serrata content to make different stellate snapper compound feeds and feed formulas. As shown in Table 2 (values are percentages by weight), the preparation steps are the same as in Example 1.

[0034] Table 1

[0035]

[0036] Note: a. Tapioca starch is a commercially available product, which can be purchased from the domestic raw material market;

[0037] b. Fish meal is American fish meal, crude protein content is 68%, and fish oil content is 9.4%;

[0038] c. Asparagus powder protein content is 19.14%, fat content is 0.5%, crude fiber content is 5.8%, ash content is 28.77%, amino acid content (g / 100g, dry weight): Threonine (Thr) * 0.70, Valine Acid (Vla)* 1.11, Methionine (Met)* 0.53, Isoleucine (Ile)* 0.94, Leucine (Leu)* 1.32, Phenylalanine (Phe)* 0.83, Lysine (Lys)* 0.89, Histidine (His)* 0.21, Trypto...

Embodiment 3

[0043] With the formulated feed prepared in Example 1, about 11-12 g of snapper scorpion were reared. This embodiment is a cage culture of fish rafts at sea. The culture cage is 1×1×1.5m and has a covered net to prevent escape and seabirds. There are 3 parallel trials in each group, and 30 fish in each parallel trial. The temperature during the cultivation period was 20-26°C and the salinity was 27-31°C. After 60 days of cultivation, the growth indicators were measured. The results of Example 1 are shown in Table 3.

[0044] table 3

[0045] Group Ⅰ(0) Ⅱ (5%) Ⅲ (10%) Ⅳ (15%) Ⅴ (20%) Initial average weight (g) 11.83±0.10 12.17±0.54 11.78±0.56 11.06±0.34 11.78±0.64 Average final weight (g)24.24±0.47 cd 25.01±0.60 bc 25.03±0.27 bc 26.61±0.41 a 25.75±0.38 ab Weight gain rate (%)1.11±0.09 b 1.06±0.04 b 1.13±0.08 b 1.41±0.09 a 1.05±0.05 b SGR1.19±0.04 b 1.20±0.03 b 1.26±0.06 b 1.47±0.03 a 1.31±0.07 b Survival rate (%)83.33±0.02 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com