Grooving machine

A rolling grooving machine and rolling grooving technology, applied in metal processing equipment, feeding devices, positioning devices, etc., can solve the problems that professional equipment cannot meet the diversification of equipment production, increase the cost of basic expansion, and cannot meet the production requirements of users, etc. , to achieve the effects of controllable rolling groove depth, strong applicability and high processing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

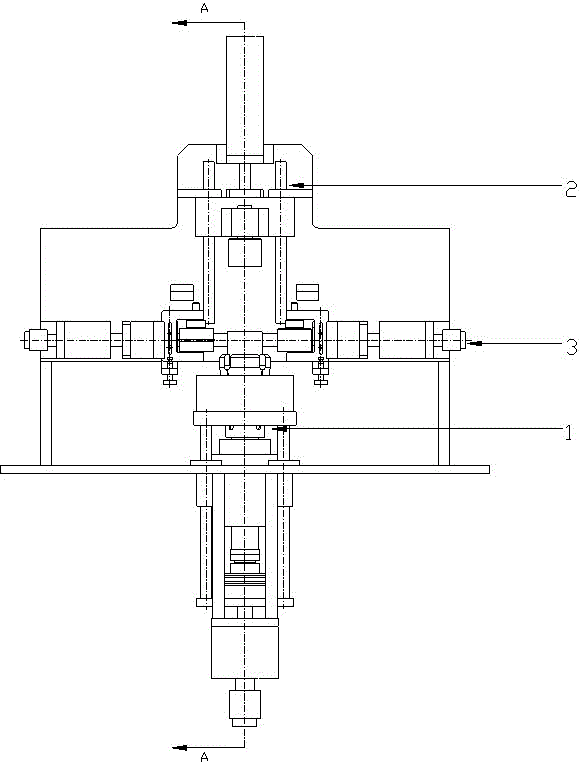

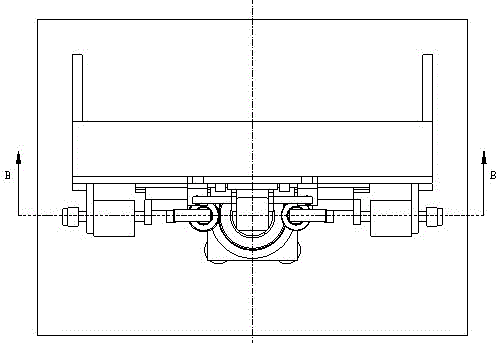

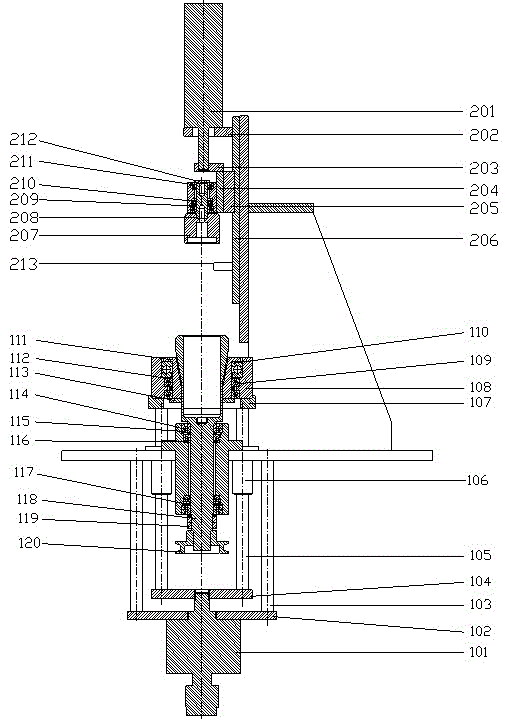

[0024] Such as Figure 1 to Figure 4As shown, the grooving machine of the present invention includes a side platform and a positioning mechanism 2, a grooving mechanism 3 and a clamping mechanism 1 arranged on the side platform in sequence; the positioning mechanism 2 includes a positioning power source 201, a positioning power Source fixing plate 202, positioning slide block 205, positioning guide rail 206, positioning block 207, positioning shaft 208, positioning bearing seat 209; positioning power source fixing plate 202 is fixed on the side platform, and positioning power source 201 is fixed on the positioning power source fixing plate 202 side surface, the positioning guide rail 206 is fixed on the side platform, the front and rear ends of the positioning slider 205 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com