A processing method for the steam seal arc section of a steam turbine in a power station

A processing method and steam turbine technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems affecting the machining accuracy of the steam seal arc section of the steam turbine in the power station, the steam seal teeth are easy to fall, the ring is easily deformed, etc. The effect of installation fixed time, preventing steam seal teeth from lodging, and avoiding stress release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

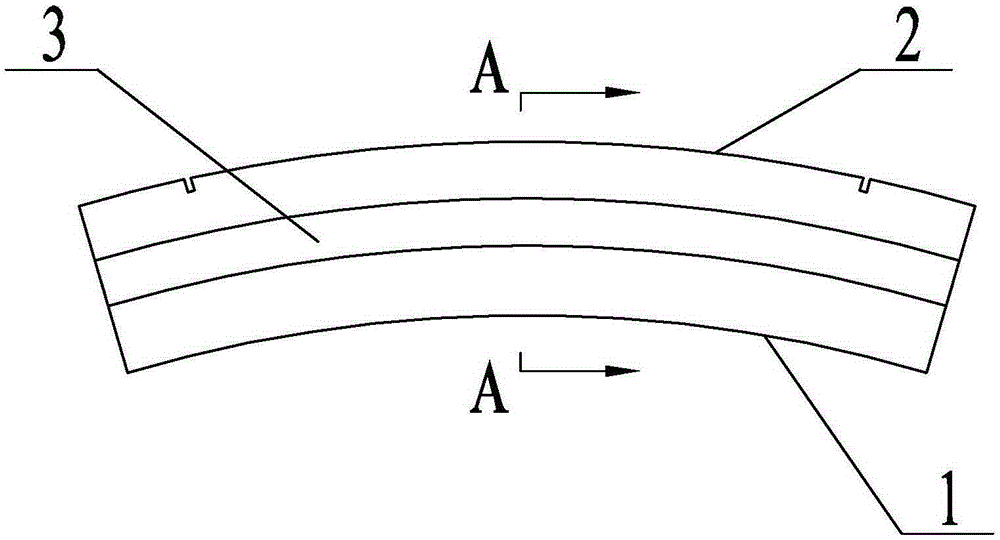

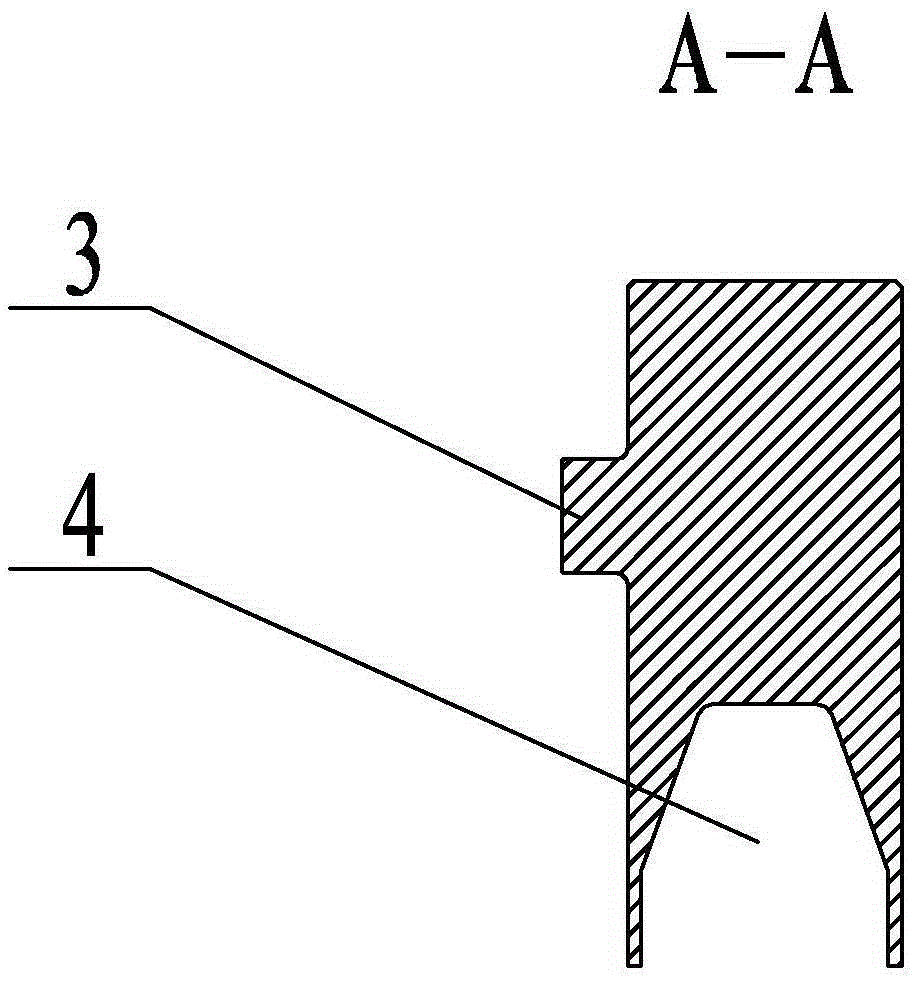

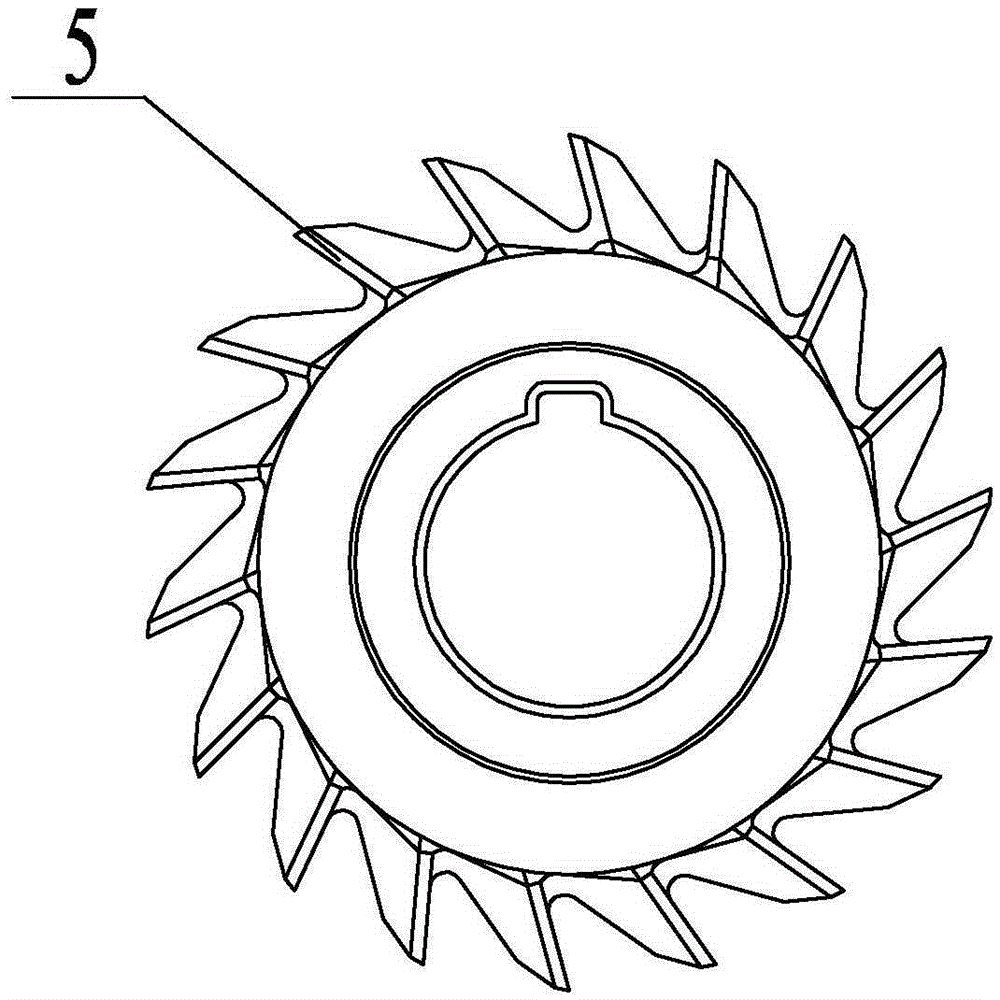

[0016] Specific implementation mode one: combine Figure 1 to Figure 4 Illustrate, the steam turbine steam seal arc section processing method of the power station described in the present embodiment is realized according to the following steps:

[0017] Step 1: Rough machining of the arc-shaped blank of the steam seal, milling the inner arc surface 1, the outer arc surface 2, the upper and lower bottom surfaces and the radiating surfaces at both ends of the arc section of the arc section of the steam seal. The machining allowance of each processing surface is 1.8 mm~2.2mm,

[0018] Step 2: Temper the steam seal arc section after milling, the tempering temperature is 690 ° C ~ 740 ° C, the tempering time is at least 12 hours, air cooling after tempering,

[0019] Step 3: Milling the upper and lower bottom surfaces of the steam seal arc section, the machining allowance of each surface is 0.18mm ~ 0.22mm,

[0020] Step 4: Grinding the upper and lower bottom surfaces of the arc ...

specific Embodiment approach 2

[0025] Specific implementation mode two: combination Figure 1 to Figure 4 Note that the feed fz of the semi-finishing inner arc surface 1, outer arc surface 2 and arc boss 3 in step five of the present embodiment is 0.15mm / tooth. The selected feed rate fz is 0.15mm / tooth, which effectively guarantees the accuracy of the shape and dimension of the arc section of the steam seal of the steam turbine.

[0026] The undisclosed technical features in this embodiment are the same as those in the first embodiment.

specific Embodiment approach 3

[0027] Specific implementation mode three: combination Figure 1 to Figure 4 Note that the feed rate fz for finishing the inner arc surface 1, the outer arc surface 2 and the arc boss 3 to the standard size in step six of this embodiment is 0.10mm / tooth.

[0028] The undisclosed technical features in this embodiment are the same as those in the first or second specific embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com