Automatic polishing machine for flange surface of rotary body

A technology of automatic polishing and rotating body, applied in the field of polishing machines, can solve the problems of flange surface effect, reduce efficiency and quality, increase equipment complexity and operation difficulty, simplify the complexity and operation difficulty, and reduce coordination operations. time, improved efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

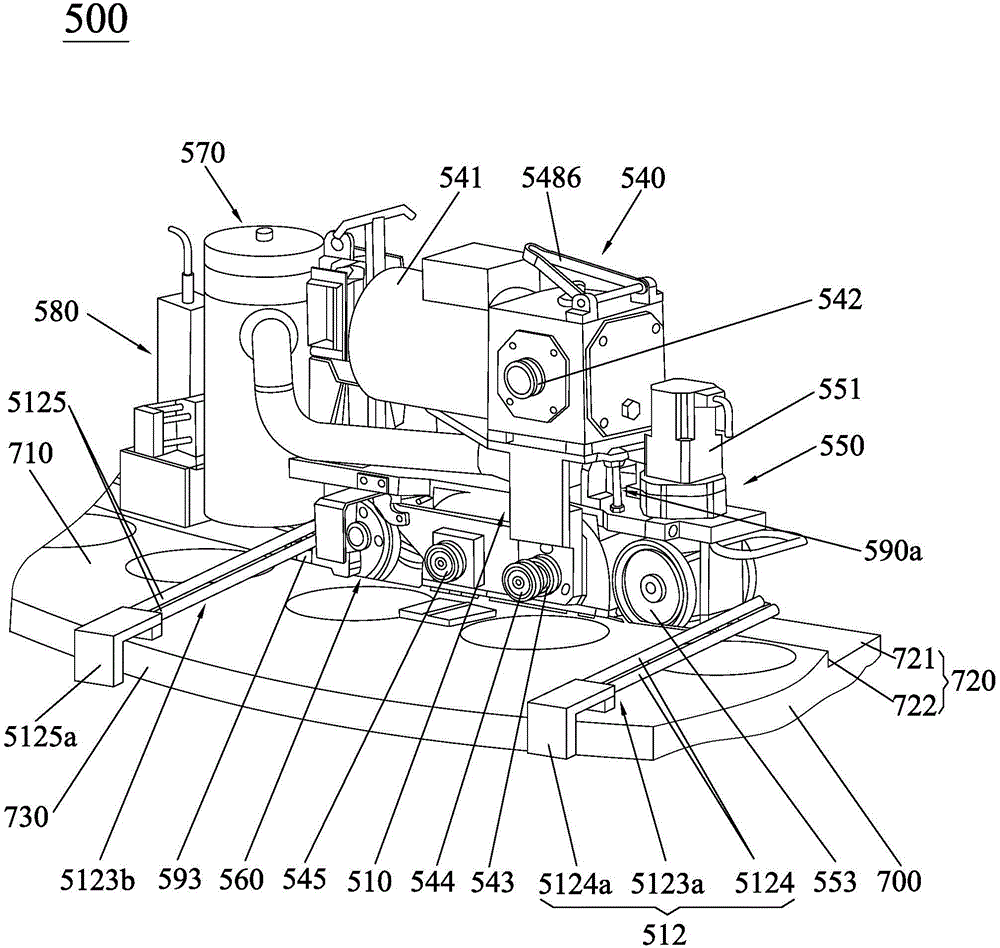

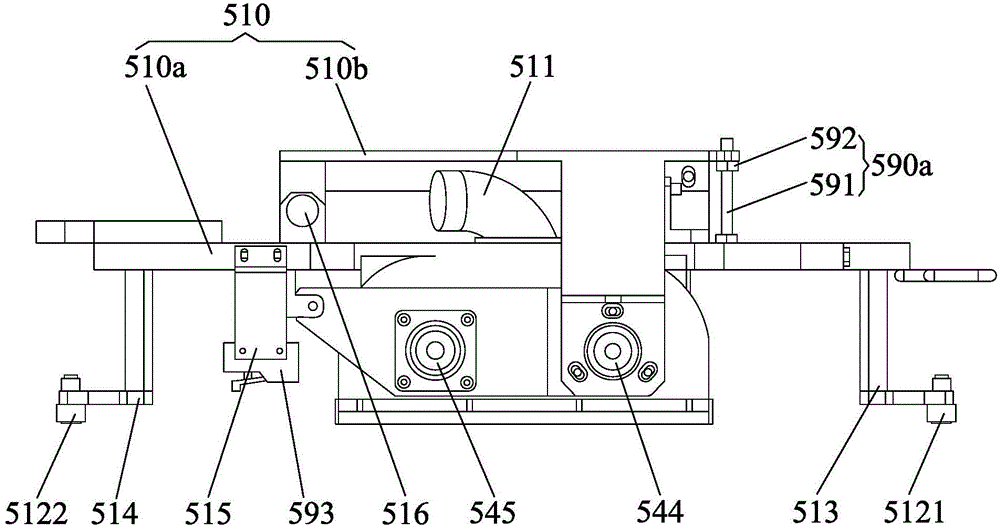

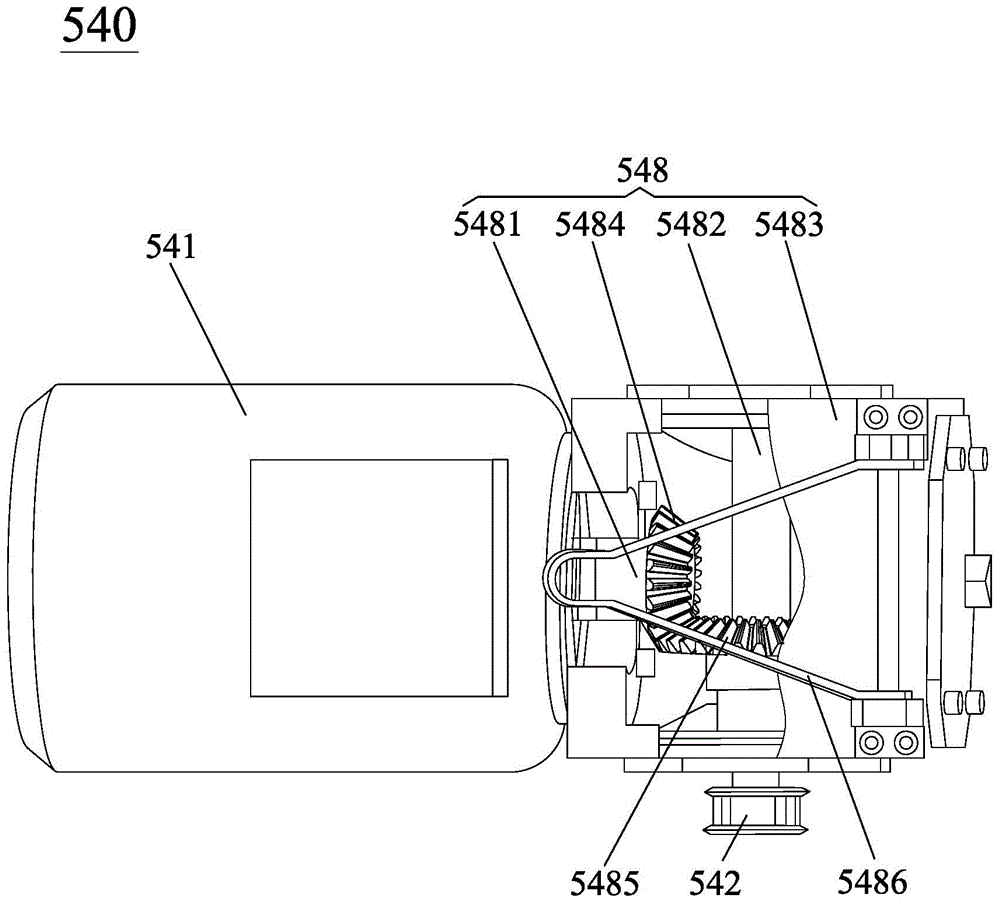

[0037] see figure 1 and figure 2 ,as well as Figure 6 and Figure 7 , the rotary body flange surface automatic polishing machine 500 of the present invention is electrically connected with the controller, and the flange surface of the large rotary body 700 (not noted in the figure) is polished and polished, so that the flange surface of the rotary body 700 and the large-scale rotary body 700 has a guide track 720 around the center line of the large-scale rotary body 700. Specifically, the guide track 720 includes a support surface 721 and a guide side surface 722. The support surface 721 is staggered below the top surface 710 of the large-scale rotary body 700, of course, it can also be located under the top surface 710 of the large-scale rotary body 700, so that the support surface 721 and the top surface 710 are no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com