A lightweight assembled wheel

An assembled and lightweight technology, applied to spoked wheels, wheels, rims, etc., can solve the problems of high maintenance cost and waste, and achieve the effects of small exposed area, low maintenance cost and good vibration absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

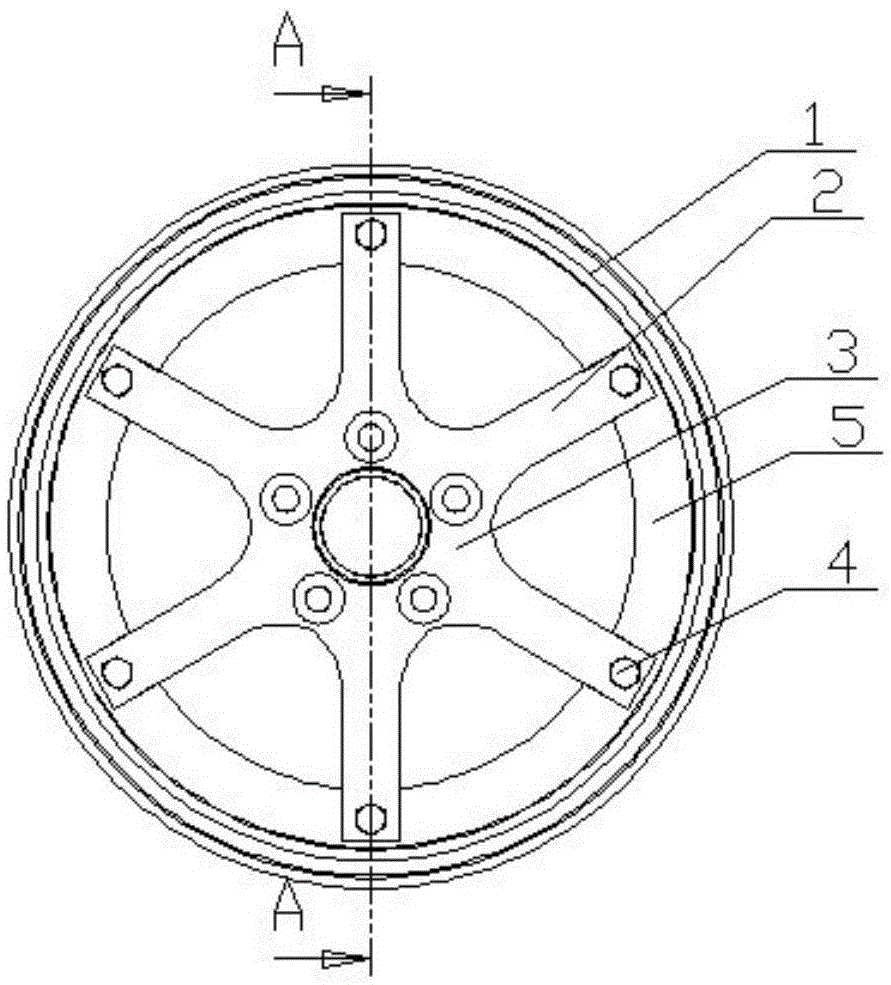

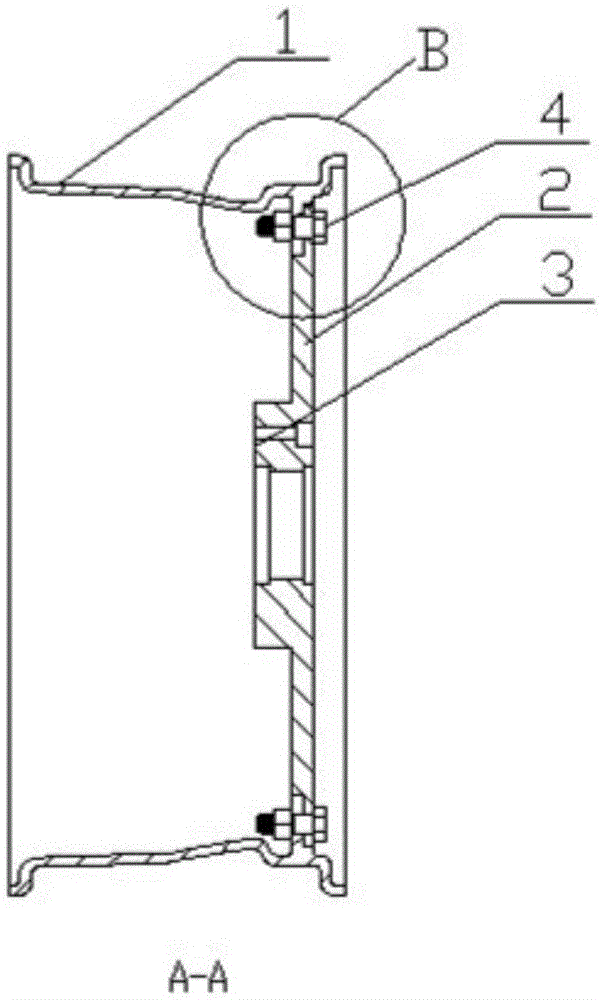

[0015] Specific implementation mode 1. Combination Figure 1 to Figure 3 Describe this embodiment, a lightweight assembled wheel, which is composed of a rim 1, a spoke 2, a hub 3 and an anti-loosening bolt 4; It is a 30mm annular mounting boss 5; the hub 3 and the spoke 2 are integrally formed by forging or die-casting aluminum alloy; Mount on the boss 5 to assemble the magnesium-aluminum alloy assembled wheel.

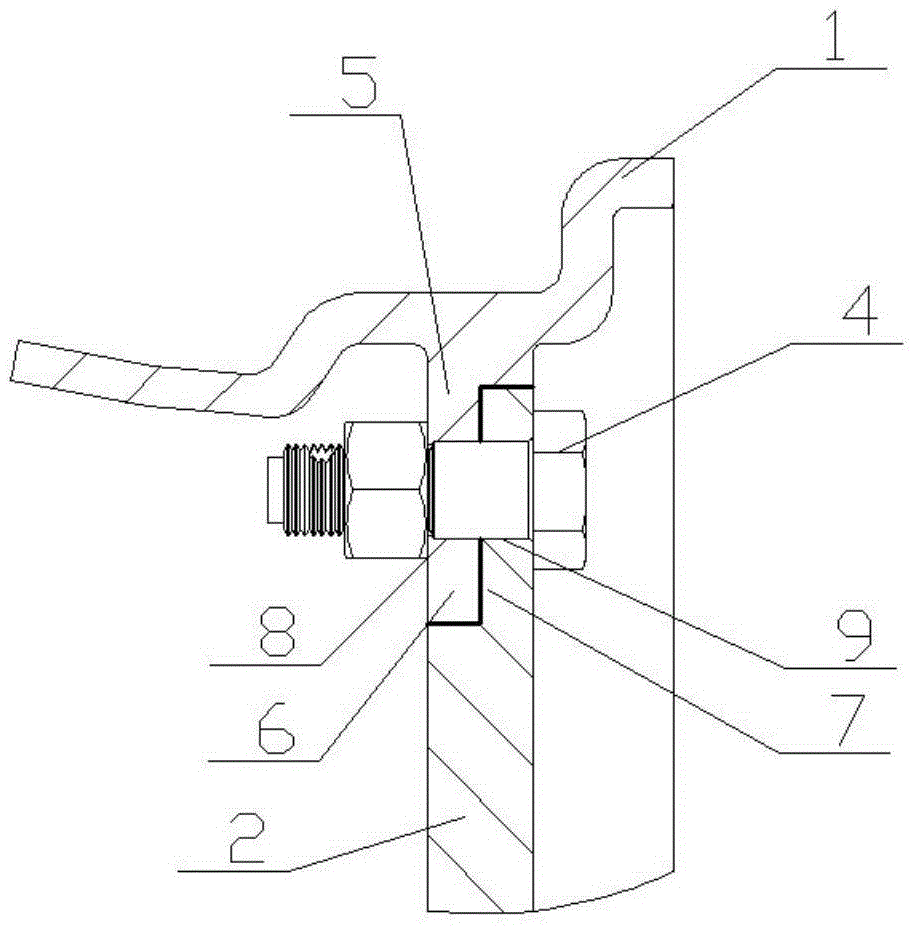

[0016] combine figure 1 , figure 2 image 3 There are six circumferential positioning grooves 6 and first mounting holes 8 evenly distributed along the circumferential direction on the annular mounting boss 5 inside the rim 1, and there are radial positioning notches 7 and second mounting holes 9 on the outer edge of the spoke 2, The circumferential positioning groove 6 and the radial positioning notch 7 play the role of positioning the spoke 2 relative to the rim 1 during installation; 7 is placed in the axial positioning groove 6. After the positioning is comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com