Bridge expansion joint structure

A technology of expansion joints and bridges, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of easy fracture of section steel, large amount of expansion, and low rigidity, so as to improve driving comfort, reduce impact, and buffer impact load Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

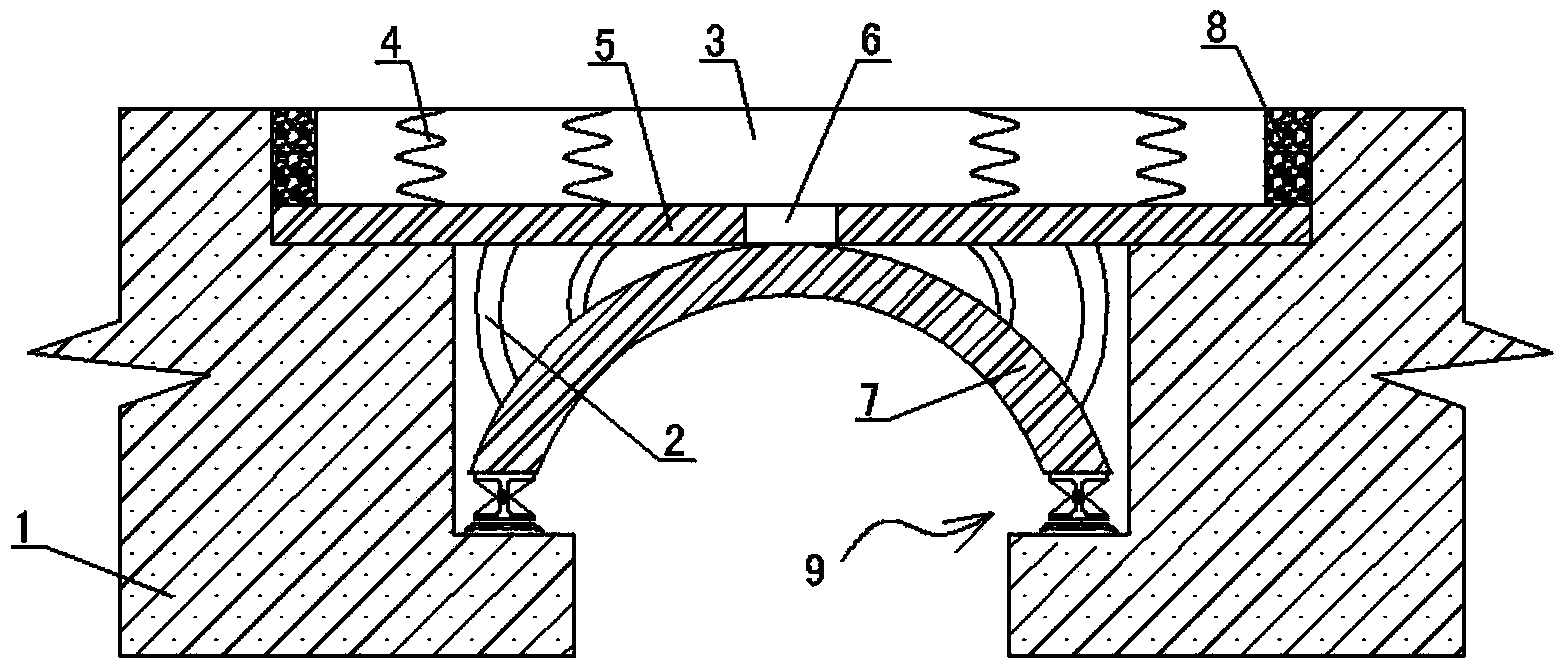

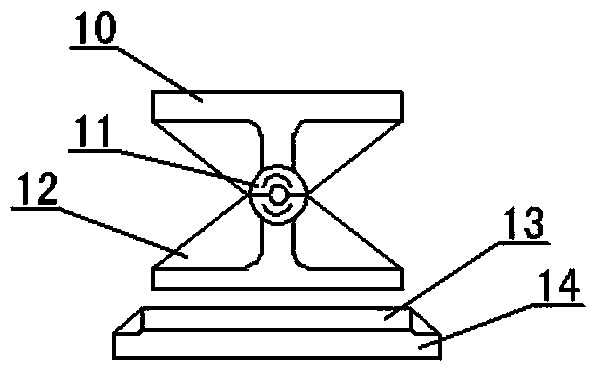

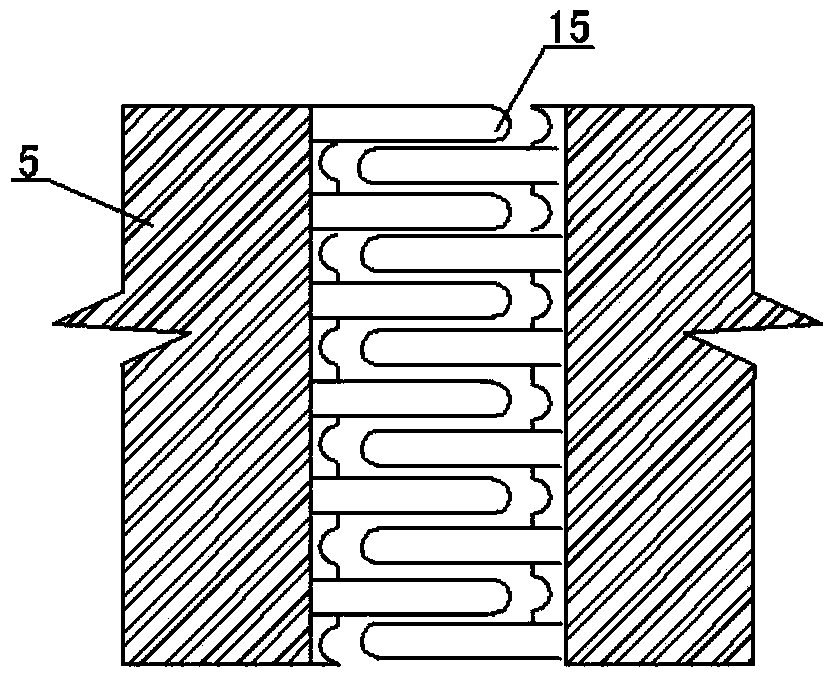

[0023] See figure 1 In this embodiment, the structural form of the bridge expansion joint is: for the expansion joint between the adjacent section beams 1, the top plane of the expansion plate 5 arranged in the expansion joint is lower than the height of the bridge deck to form a concave platform, A replaceable paving layer 3 is set on the concave platform, and the top surface of the paving layer 3 is level with the bridge deck. The reserved gap between the paving layer 3 and the bridge deck is filled with foam caulking material 8 , Foam joint filler 8 is light in weight, high in specific strength, can absorb impact load, has good heat insulation and sealing performance; a support structure is provided at the bottom of the expansion plate 5, and the support structure is to erect an arch between the beams 1 on both sides of the expansion joint The supporting body 7 is provided with supporting rods 2 on the arched supporting body 7. The telescopic plate 5 is jointly supported by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com