Offshore wind turbine foundation anti-collision structure

An offshore wind turbine and basic technology, applied in shipping equipment, climate change adaptation, etc., can solve the problems of maintenance personnel crushing, casualties, and undesigned anti-collision structures, so as to improve operational safety, safety and reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

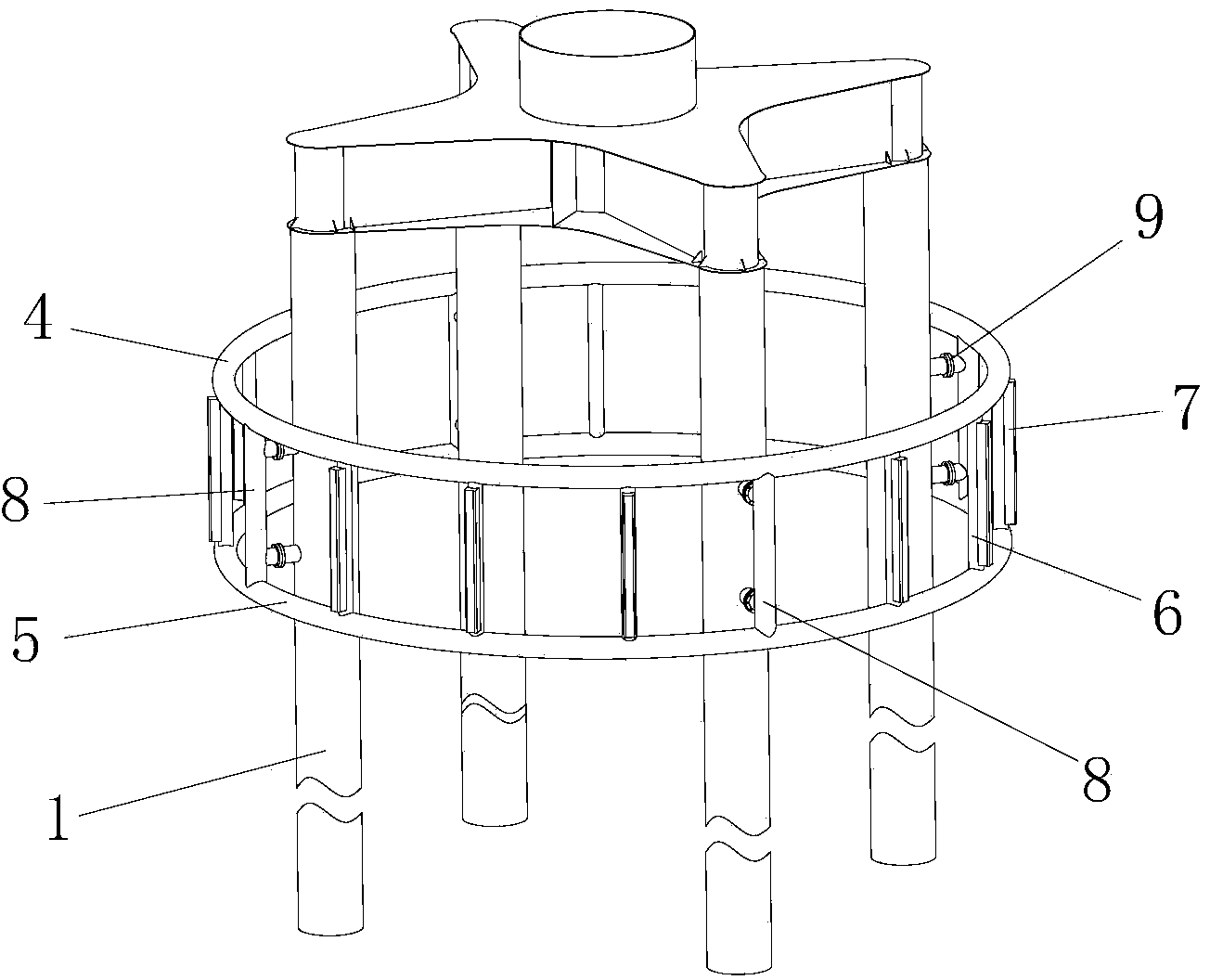

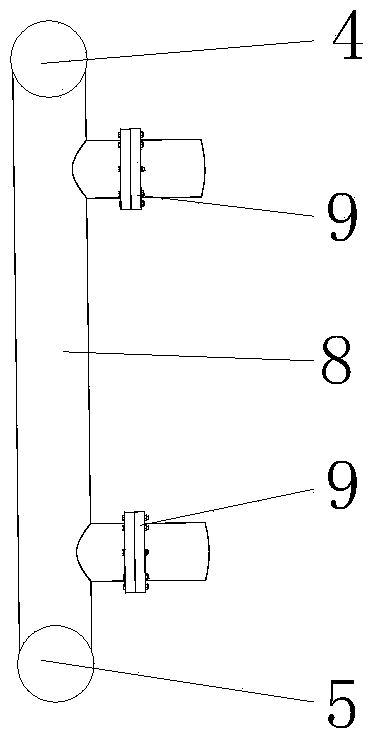

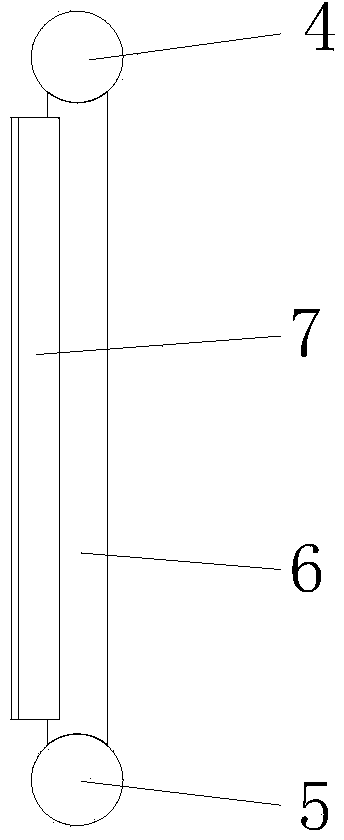

[0013] refer to Figure 1 to Figure 3 , an offshore wind turbine foundation anti-collision structure, including foundation legs 1, the foundation legs 1 generally have 3-8 pieces, the foundation legs 1 are installed with anti-collision devices, and the anti-collision devices include The upper circular tube ring 4 and the lower circular tube ring 5 of the foundation pile leg 1, a number of vertical circular tubes 6 are arranged between the upper circular tube ring 4 and the lower circular tube ring 5, and the vertical circular tubes 6 are A rubber sleeve 7 is installed, and the rubber sleeve 7 can buffer the collision force. The two ends of the vertical circular pipe 6 are directly welded on the upper circular pipe ring 4 and the lower circular pipe ring 5 .

[0014] Between the upper circular pipe ring 4 and the lower circular pipe ring 5, there are vertical support pipes 8 equal in number to the foundation legs 1, and the two ends of the vertical support pipes 8 are directly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com