Multi-branch disk square bored pile

A technology of drilling and pouring and pile body, which is applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problem of not giving full play to the lateral resistance and end resistance of the rock and soil layer, so as to reduce the cost and improve the bearing capacity of the single pile. , the effect of reducing the number of piles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

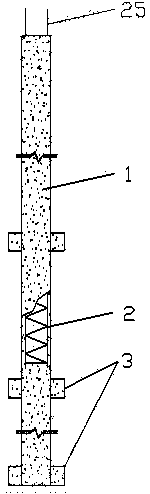

[0015] The embodiment of the present invention provides a multi-branch drilled grouting square pile, see figure 1 , figure 2 , the multi-support disc bored square pile includes a pile body 1 , a steel cage 2 arranged in the pile body 1 , and a concrete support disc 3 arranged on the pile body 1 .

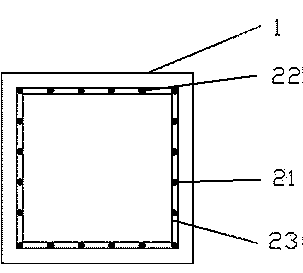

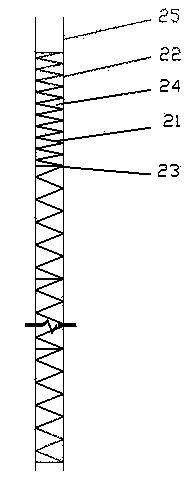

[0016] Specifically, see image 3 , The reinforcement cage 2 includes stirrups 21 , main bars 22 arranged inside the stirrups 21 , reinforcing bars 23 arranged on one side of the stirrups 21 , and densified areas 24 arranged between the stirrups 21 . The exposed end of the reinforced cage 2 after being arranged in the pile body 1 is an anchor bar 25 .

[0017] The beneficial effects brought by the technical solution provided by the embodiments of the present invention are:

[0018] In the case of the same single pile bearing capacity, reducing the cross-sectional area of the pile body or reducing the length of the pile reduces the volume of the pile body and saves materials. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com