Wall tile pasting tool

A ceramic tile and wall technology, which is applied in the direction of construction and building structure, to achieve the effect of simple and fast operation, reduction of processing procedures, and improvement of paste efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

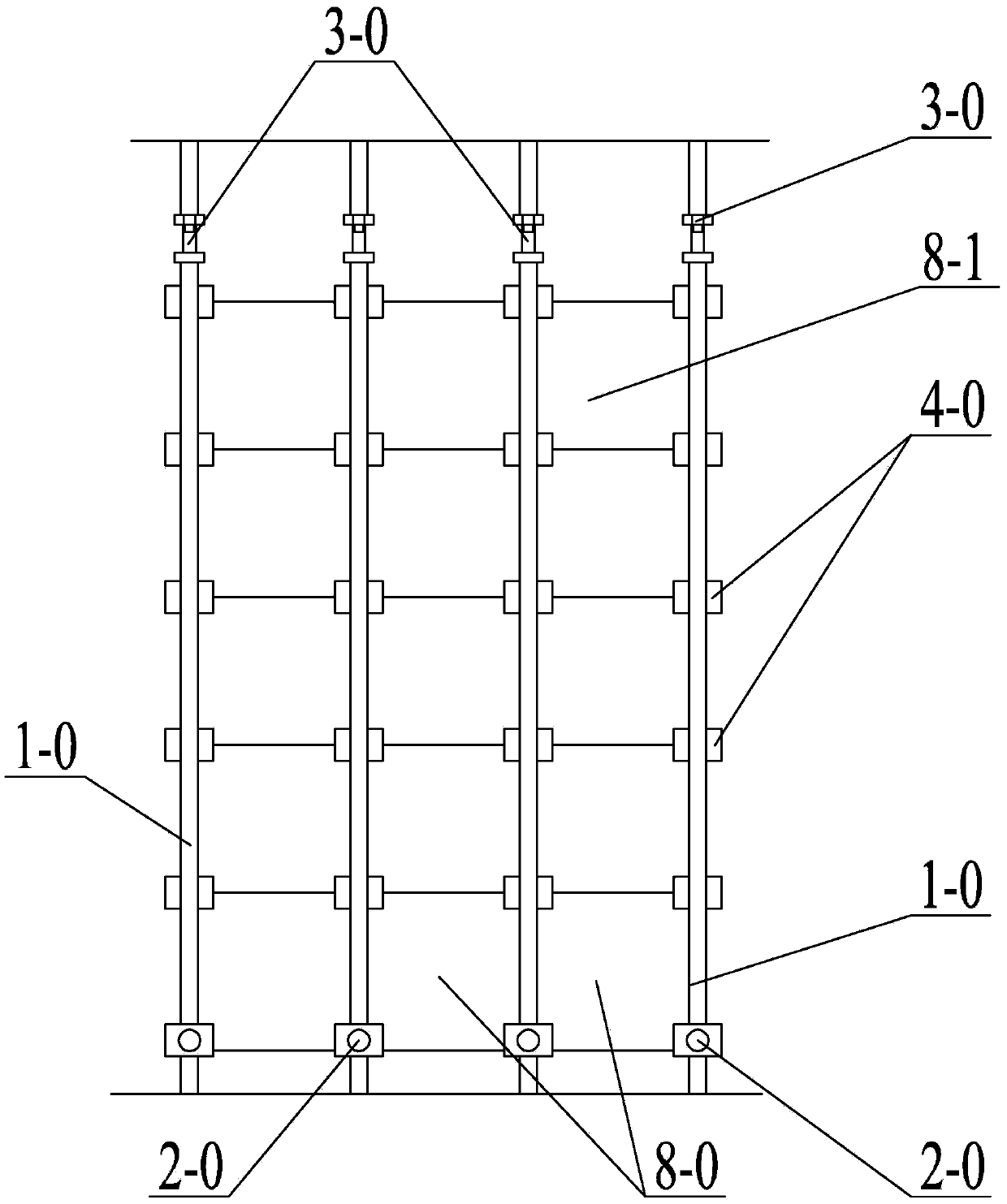

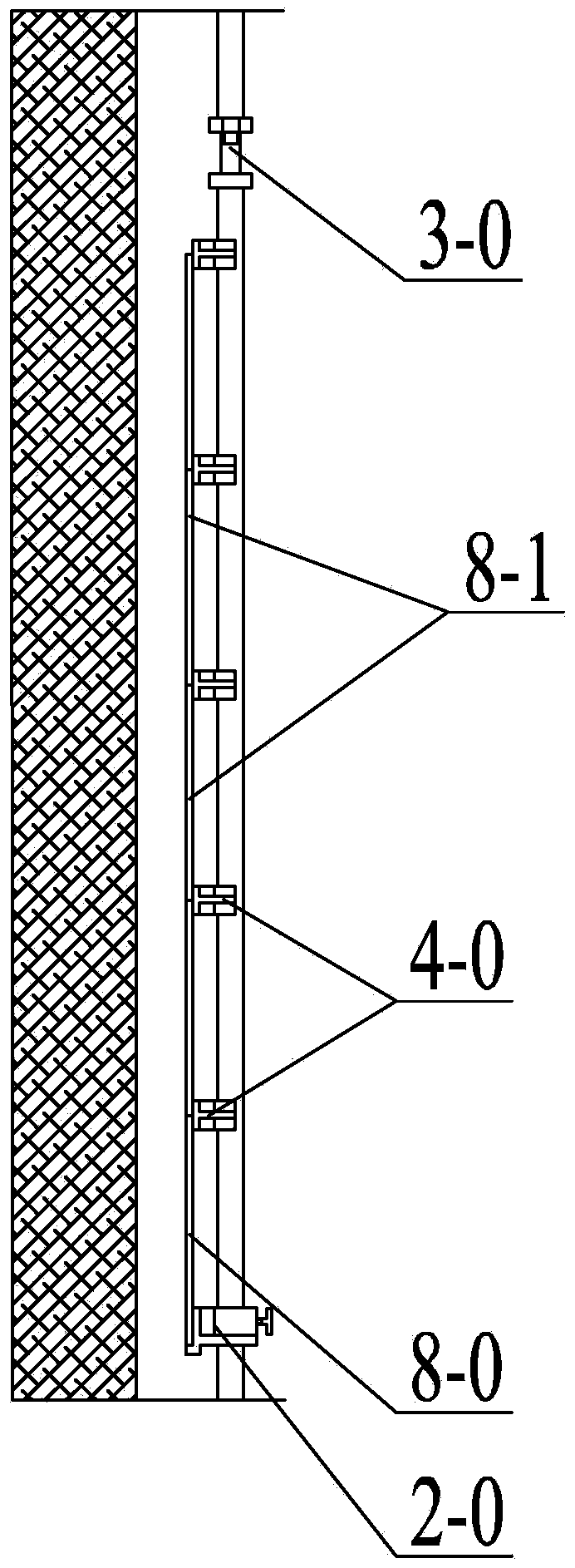

[0016] Specific implementation mode one: combine Figure 1 to Figure 27 Explain that the wall tile sticking tool in this embodiment includes several vertical rods 1-0, several reference fixing sleeves 2-0, several vertical rod fixing assemblies 3-0 and several auxiliary fixing arms 4-0 0,

[0017] The vertical rod 1-0 is an iron rod,

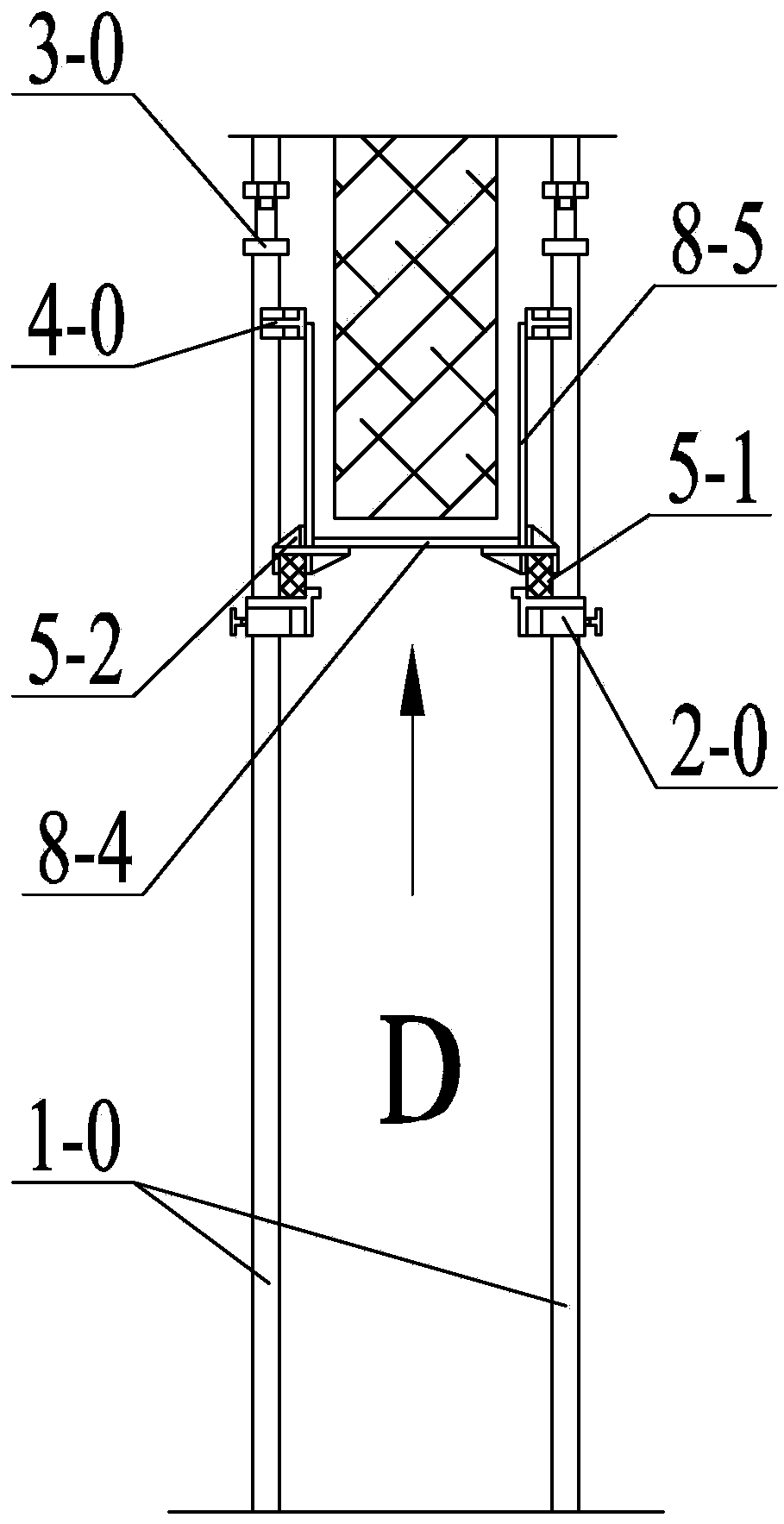

[0018] Datum fixing sleeve 2-0 comprises sleeve 2-1, horizontal plate one 2-2 and ceramic tile support arm one 2-3, sleeve 2-1 is vertically arranged, and one end of horizontal plate one 2-2 is connected with sleeve 2-2. 1 is fixedly connected, and the tile support arm 2-3 is fixedly arranged on one side of the horizontal plate 2-2 and is set close to the other end of the horizontal plate 2-2, and the side wall of the sleeve 2-1 is provided with The threaded through hole, the screw is screwed into the threaded through hole,

[0019] The vertical rod fixing assembly 3-0 includes a cylindrical boss 3-1, a sleeve 3-2, a nut 3-3 and a rod 3-4, an...

specific Embodiment approach 2

[0023] Specific implementation mode two: combination Figure 1 to Figure 27 Explain that the tile support arm 2-3 of the reference fixing sleeve 2-0 of this embodiment is vertically arranged, and the other side plate of the other end of the horizontal plate 2-2 is provided with a convex eaves 2-4, A reinforcing rib 2-5 is provided between the ceramic tile support arm 1 2-3 and the sleeve 2-1.

[0024] The reference fixing sleeve 1-2-0 of this embodiment is used for positioning and installing the plane reference tile 8-0 of the plane wall. After several vertical bars 1-0 are installed and fixed side by side close to the plane wall, each plane reference tile 8-0 The horizontal ends of 0 are placed on the protruding eaves 2-4 of two adjacent reference fixed sets-2-0 respectively, and the tile support arm-2-3 makes the reference tile 8-0 vertically arranged. Due to several plane walls Body tiles 8-1 are stacked vertically on the plane reference tiles 8-0 layer by layer in turn, s...

specific Embodiment approach 3

[0026] Specific implementation mode three: combination Figure 1 to Figure 27 Note that the tile support arm 2 4-3 of the auxiliary fixing arm 4-0 of this embodiment is vertically arranged, and a reinforcing rib 2 4-4 is provided between the tile support arm 2 4-3 and the arc-shaped plate 4-1.

[0027] The tile support arm two 4-3 is the vertical plate two 2-7, the auxiliary fixed arm one 4-0 is used in conjunction with the reference fixed sleeve one 2-0, and several flat wall tiles 8-1 are vertically built up layer by layer Starting from the plane reference tile 8-0, several tile support arms 4-3 support the four corners of the plane wall tile 8-1, so that the plane wall tile 8-1 remains vertical, and utilize the principle of magnet adsorption to make the plane wall tile 8-1 vertical. The curved plate 4-1 can be pasted on any position on the vertical bar 1-0, so that the ceramic tile pasting tool of the present invention can paste various types of ceramic tiles, between the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com