A plastic-steel window frame right-angle screw connection structure and its installation method

A technology for plastic-steel window frames and connecting structures, applied in windows/doors, building components, building structures, etc., can solve problems affecting the appearance of plastic-steel doors and windows, low welding strength, and inconvenient loading and unloading processes, achieving significant social and economic benefits Benefits, improved anti-distortion and deformation capabilities, and low manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

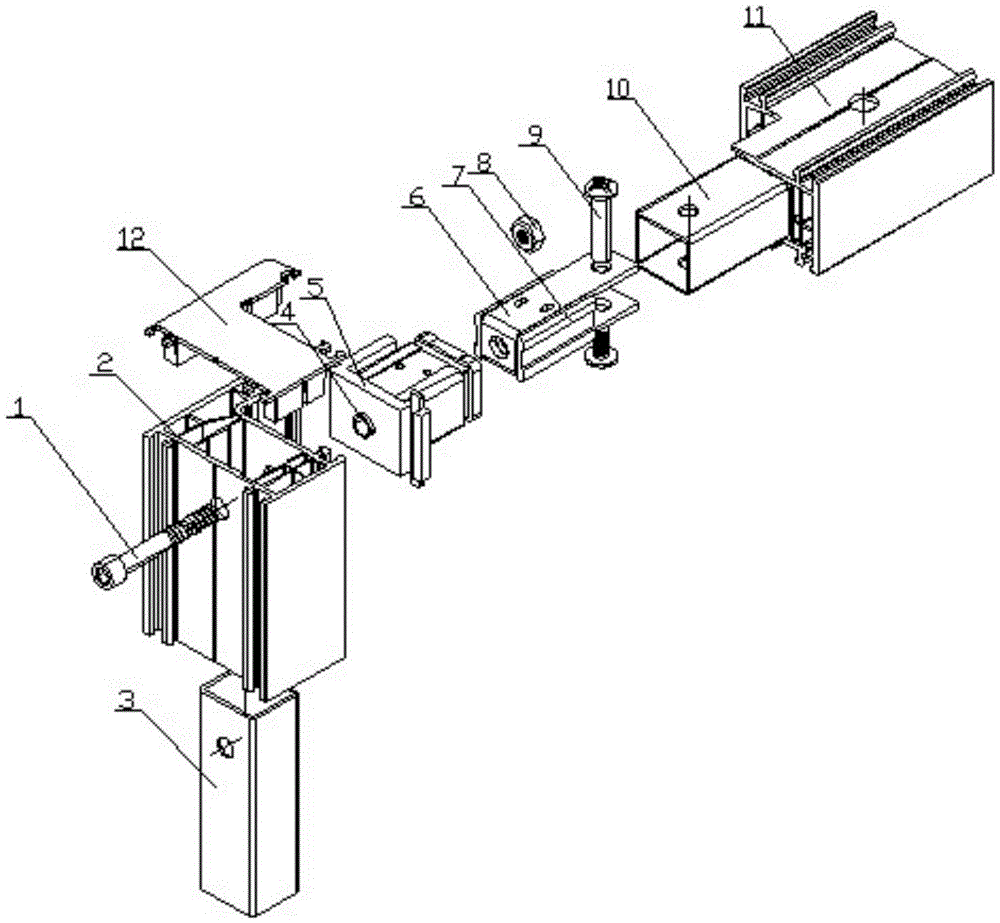

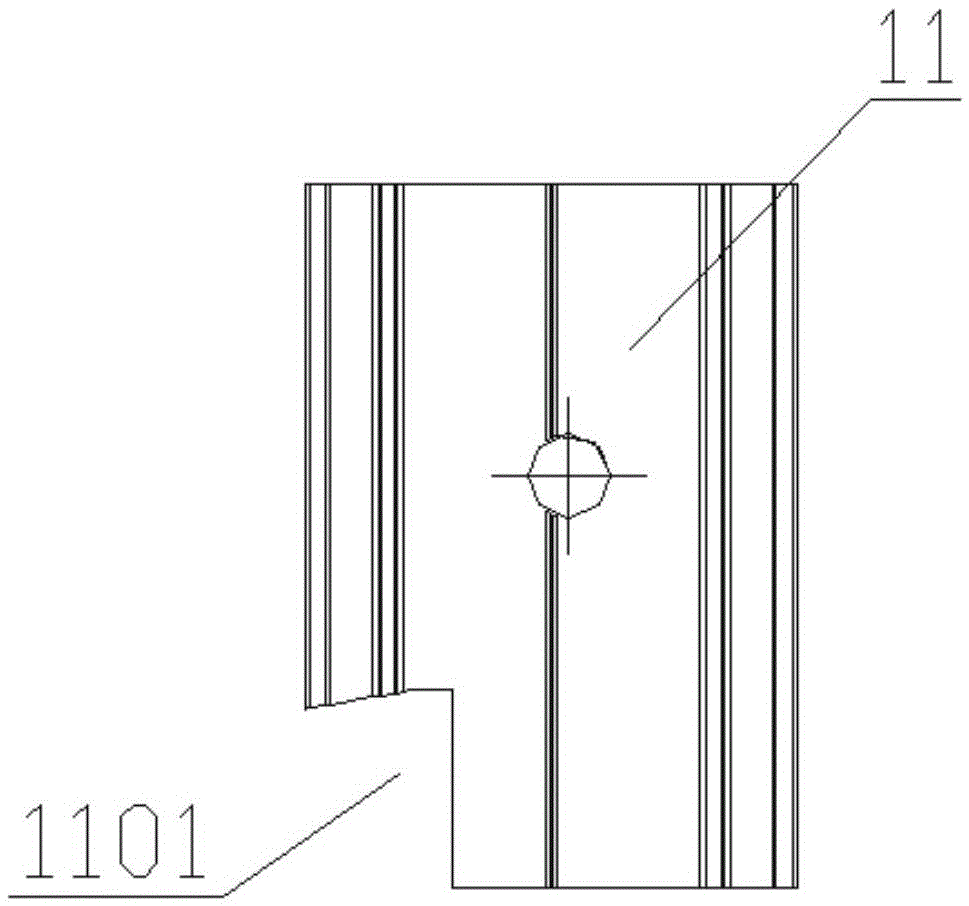

[0049] Such as Figure 1 to Figure 14 As shown, a plastic-steel window frame right-angle screw connection structure includes a first plastic-steel profile 11 and a second plastic-steel profile 2 that are perpendicular to each other, and connecting pieces. One end of the first plastic-steel profile 11 is provided with a gap 1101, and the second plastic-steel profile 2 One end is set as a vertically connected convex body 201 that matches the gap of the first plastic steel profile. The first plastic steel profile 11 and the second plastic steel profile 2 are respectively provided with pre-drilled holes; the connecting piece includes an outer sleeve, an inner insert 7 and The steel insert 6, the outer sleeve is set as a rectangular parallelepiped with an open top, the opening extends downward to form a cavity 501, a through hole is provided at the center of the bottom of the cavity, and the bottom end of the outer sleeve is also provided with a base 5 extending around. The two oppos...

Embodiment 2

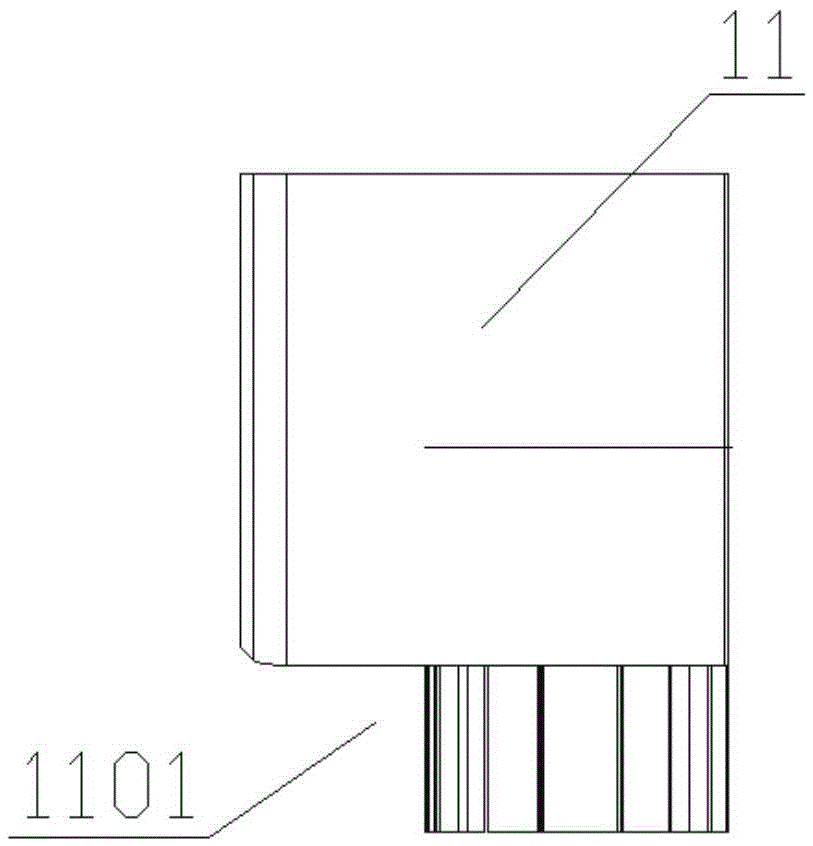

[0051] Such as Picture 10 with Picture 11 As shown, a right-angle screw connection structure of a plastic-steel window frame, the structure is as described in Example 1, the difference is that the lower surface of the outer sleeve base is provided with a cylindrical protrusion 4 perpendicular to the lower surface of the base, and a cavity The through hole at the bottom penetrates the protrusion, and the cylindrical protrusion corresponds to the pre-drilled hole on the second plastic steel profile. The pre-drilled holes of the cylindrical protrusions embedded in the second plastic steel profile enable tight fit with the pre-drilled holes and increase the firmness of the connecting piece when connecting with the second plastic steel profile.

Embodiment 3

[0053] Such as Picture 10 with Picture 11 As shown, a right-angle screw connection structure for a plastic-steel window frame, the structure is as described in Embodiment 1, and the difference is that the lower surface of the outer sleeve base 5 is provided with an upwardly recessed slot 503. When the outer sleeve is matched with the second plastic-steel profile, the slot can be snapped onto the second plastic-steel profile, which increases the firmness of the entire connecting piece when matched with the second plastic-steel profile.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com