Patents

Literature

70results about How to "Reduce welding strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

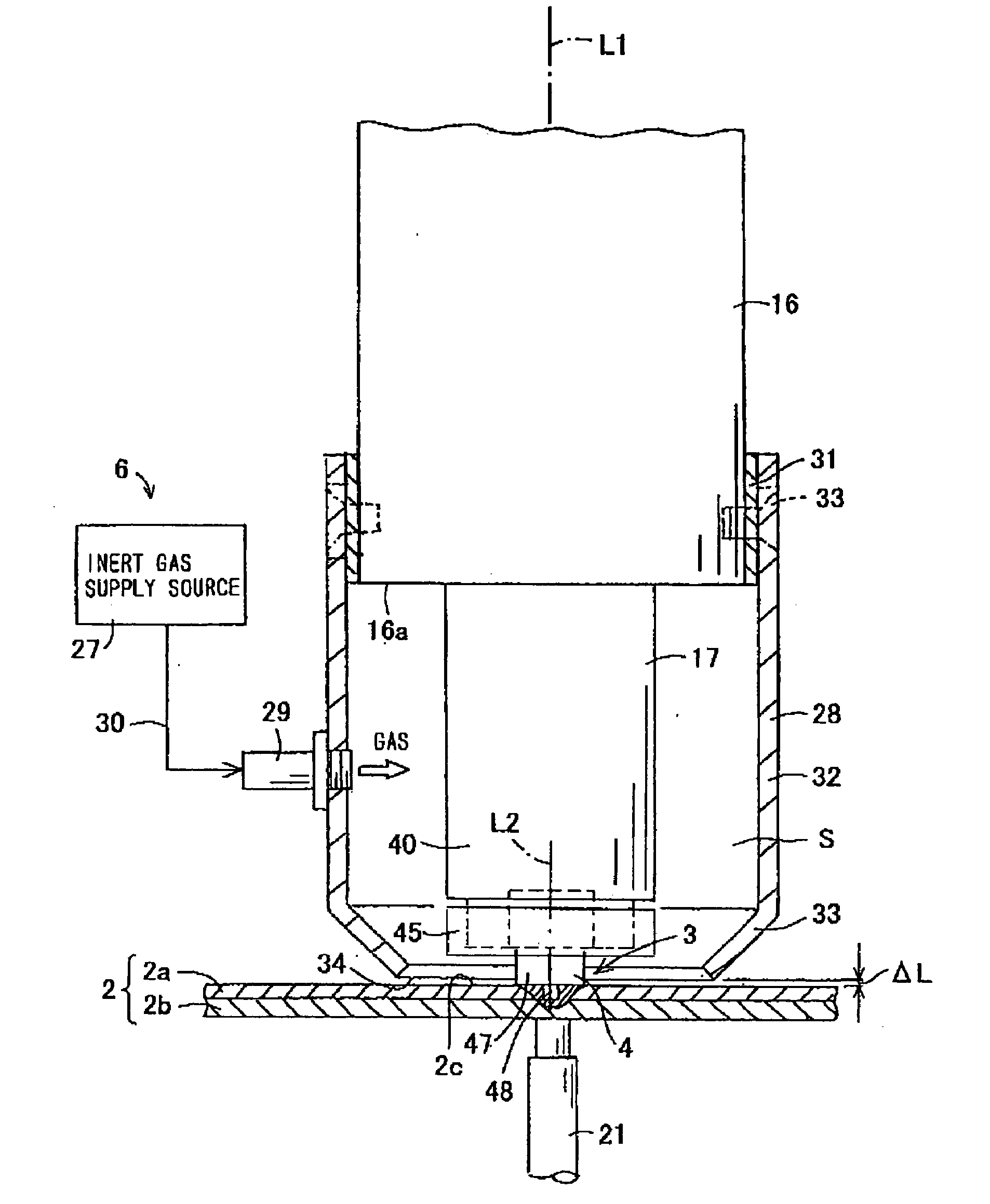

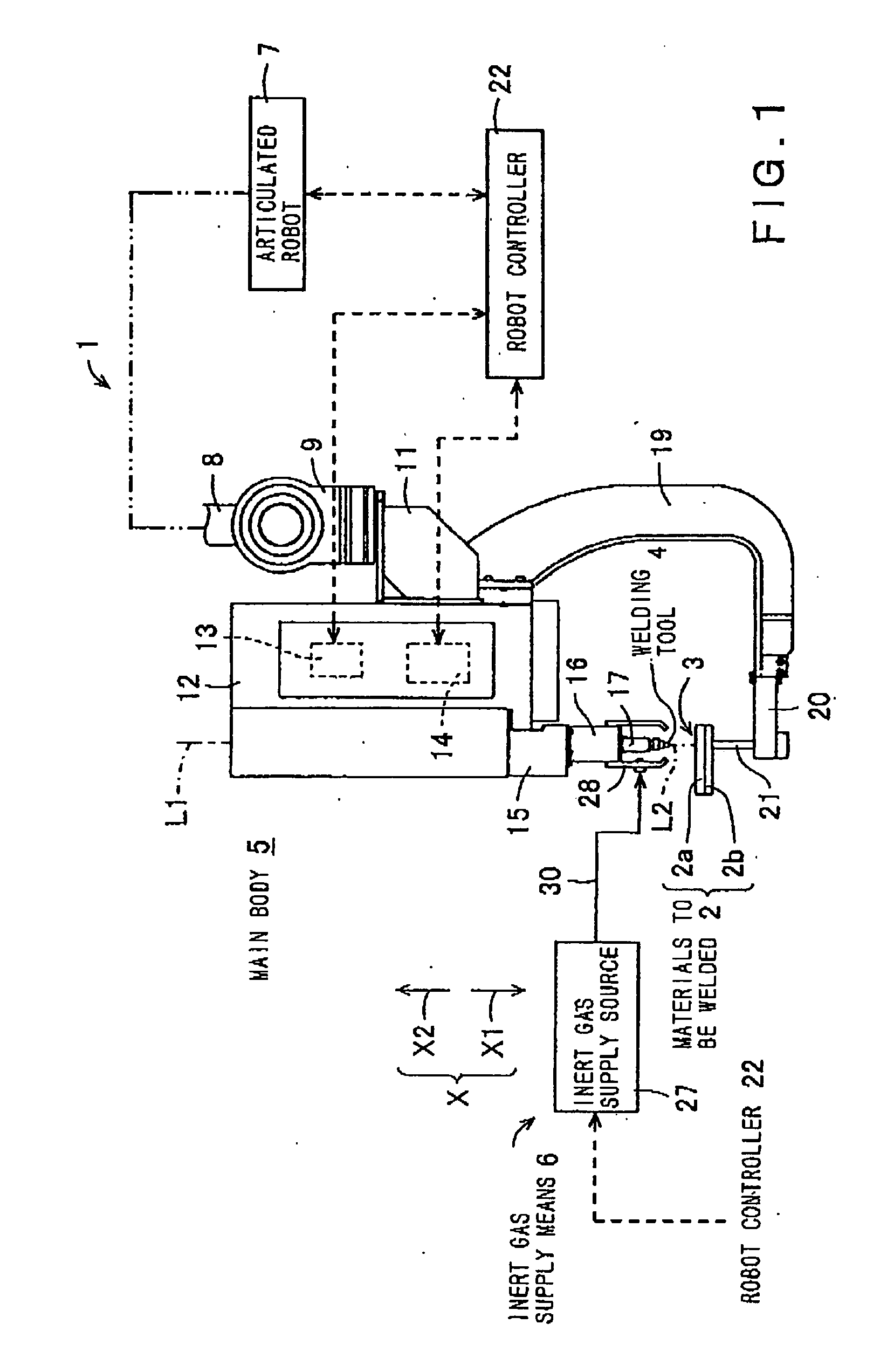

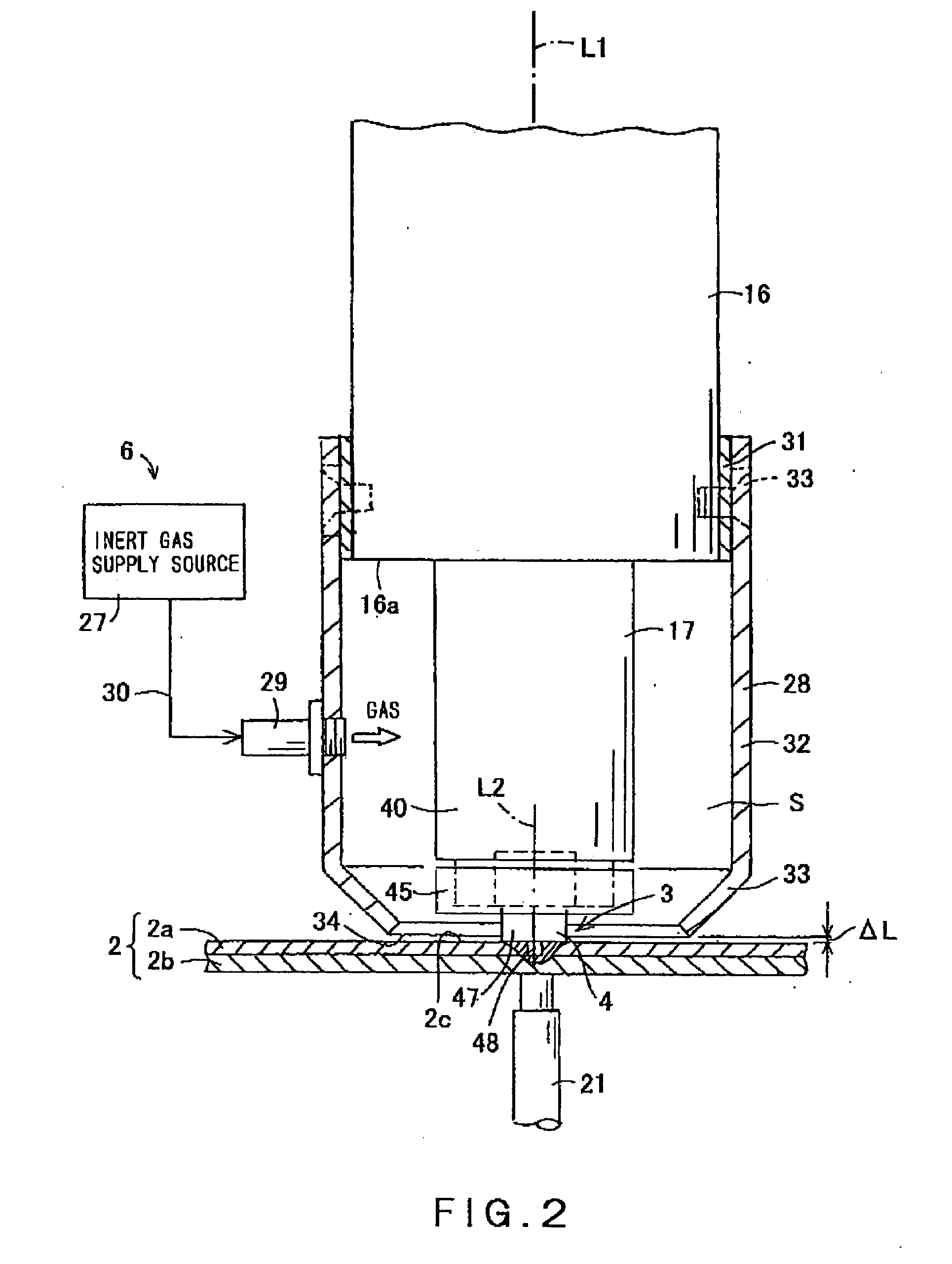

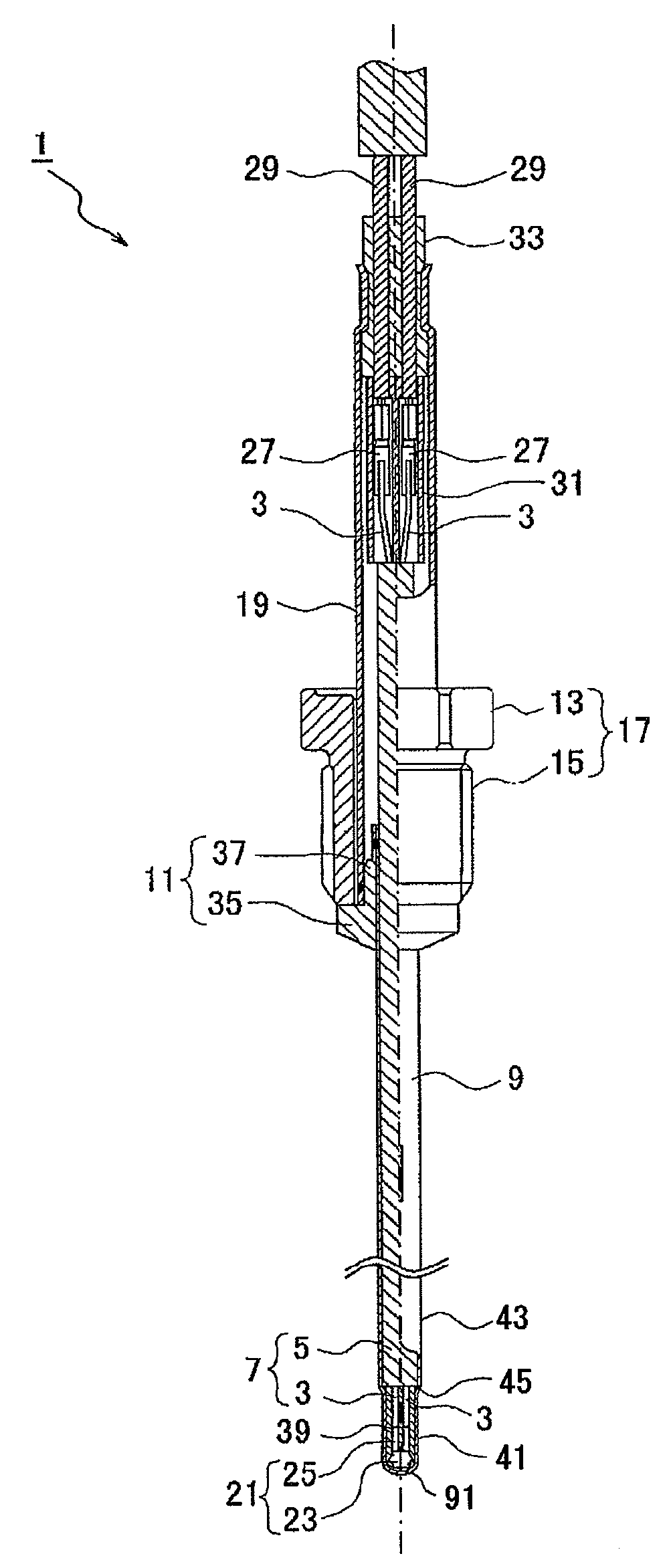

Friction stir welding machine and friction stir welding tool

ActiveUS20080023524A1Prolong lifeInhibit wearWelding/cutting auxillary devicesAuxillary welding devicesEngineeringNitride

The present invention is a friction stir welding machine adapted to perform solid phase welding on a welding portion of materials to be welded, by pressing a welding tool against the welding portion of the materials to be welded while rotating the welding tool, and forcing the welding tool to be advanced into a softened portion which is softened by a frictional heat while stirring the softened portion, wherein a coating made of aluminum nitride is formed on at least a region of the welding tool to be in contact with the materials to be welded.

Owner:KAWASAKI HEAVY IND LTD

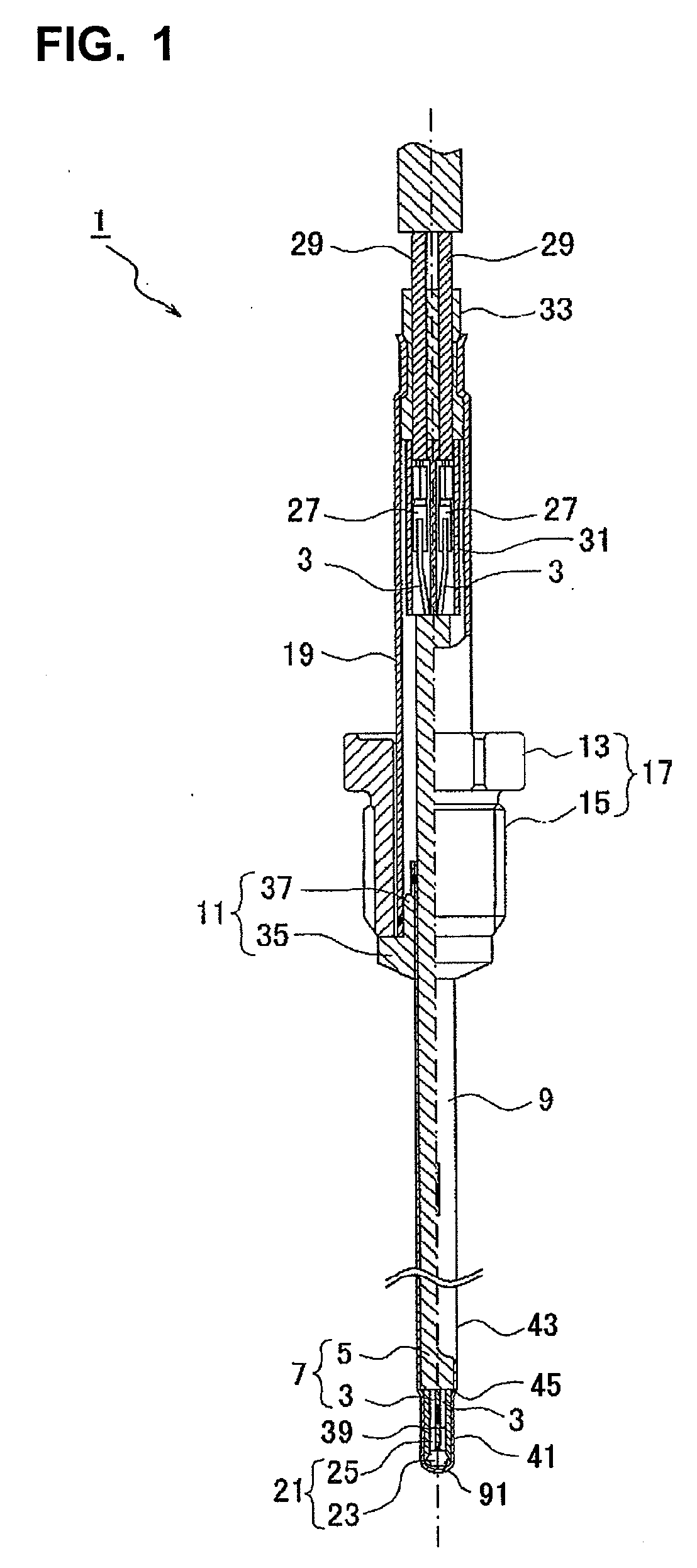

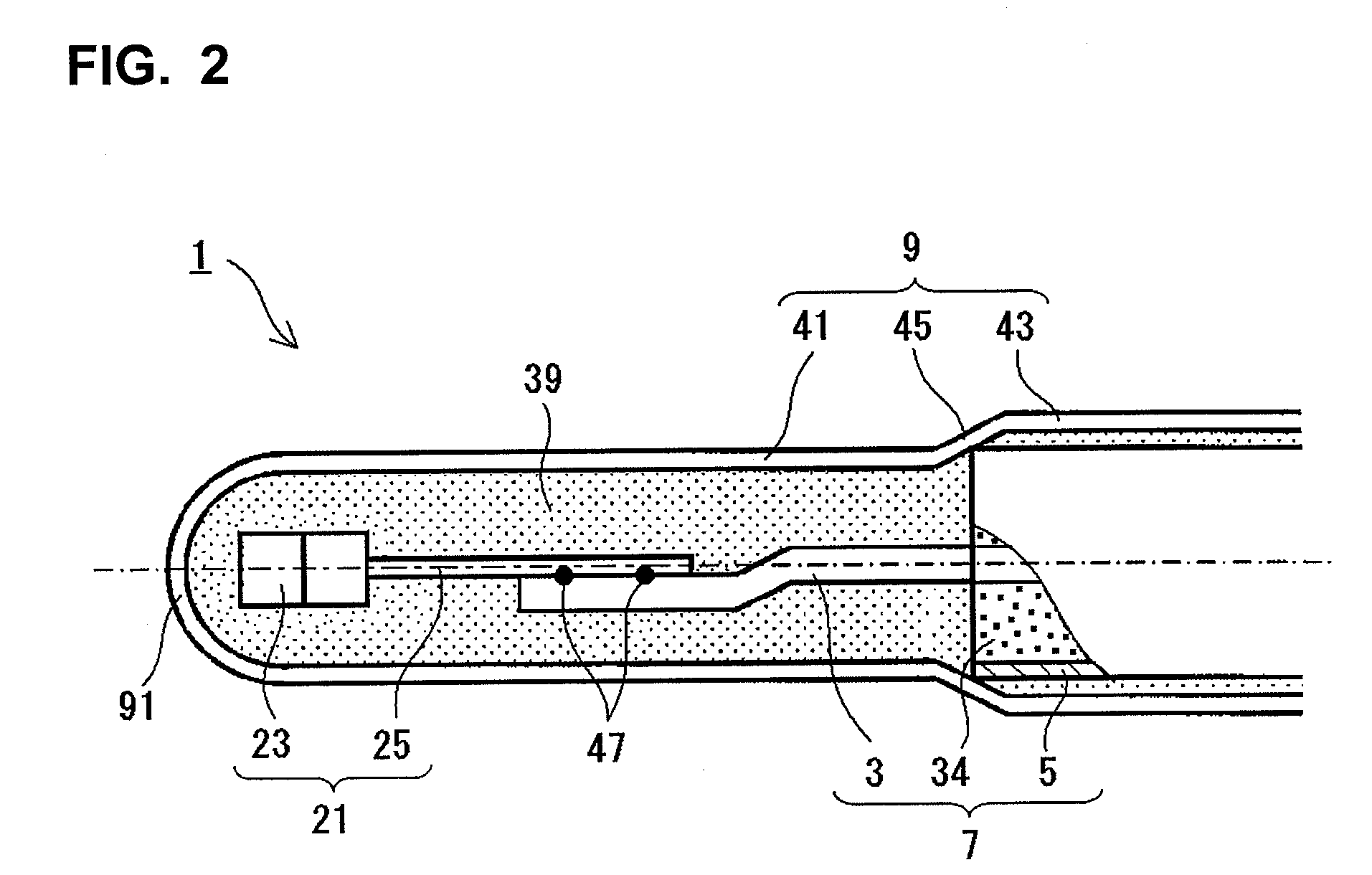

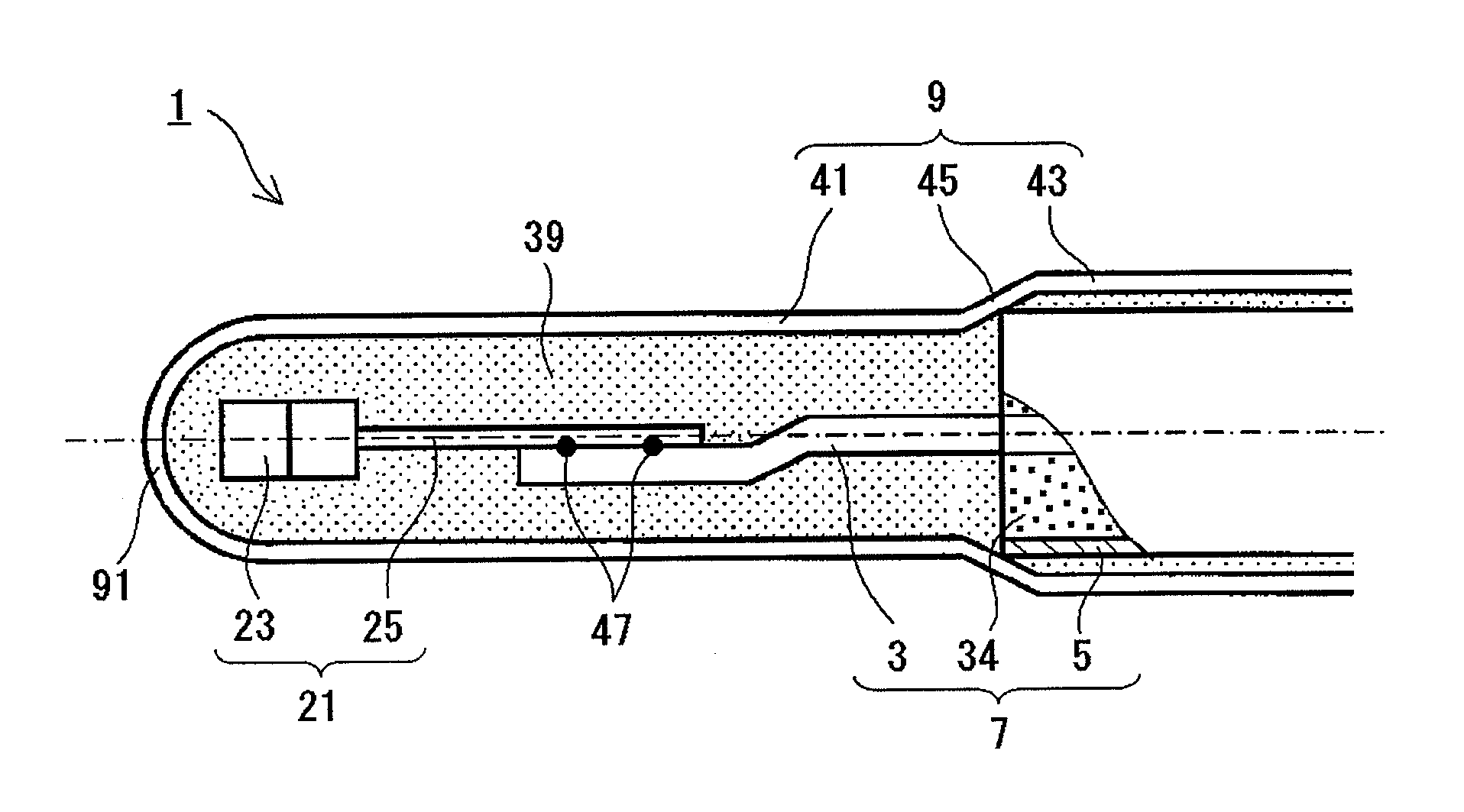

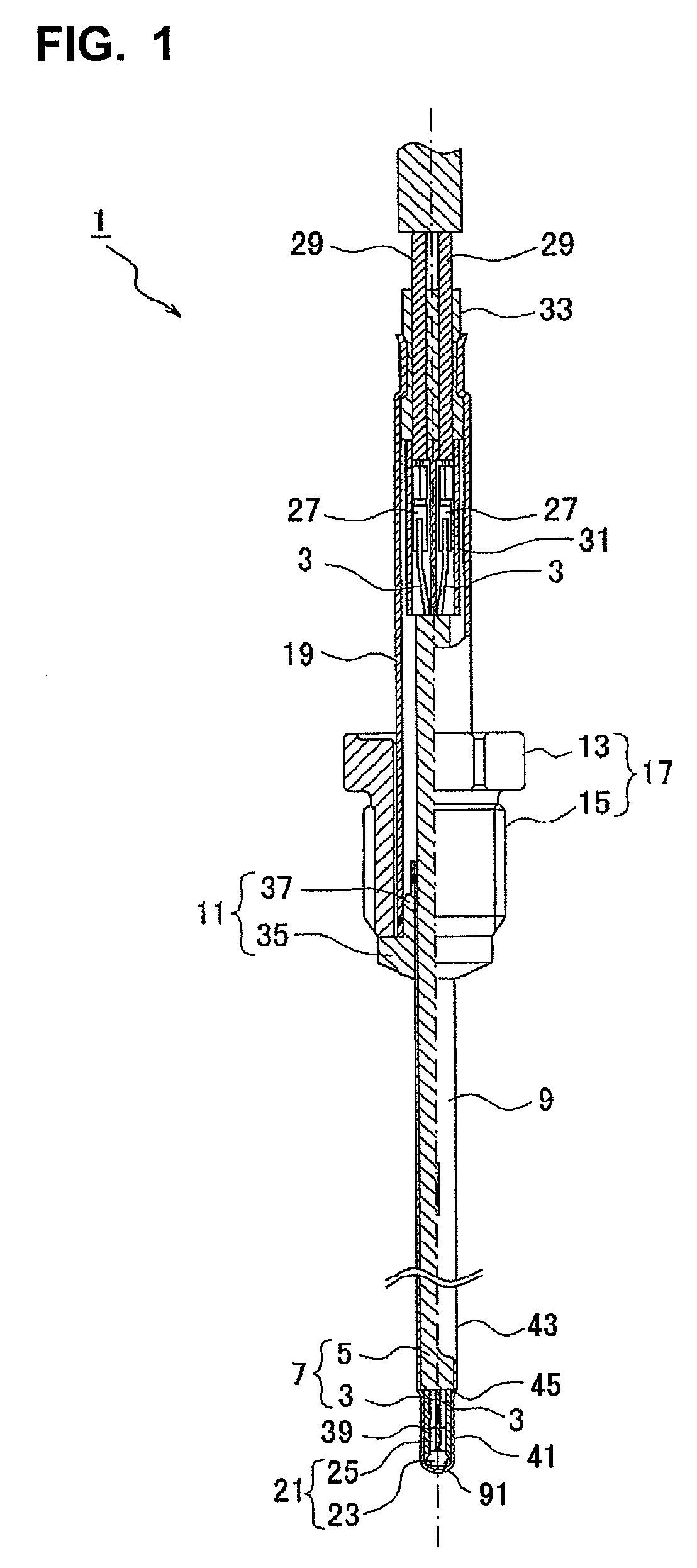

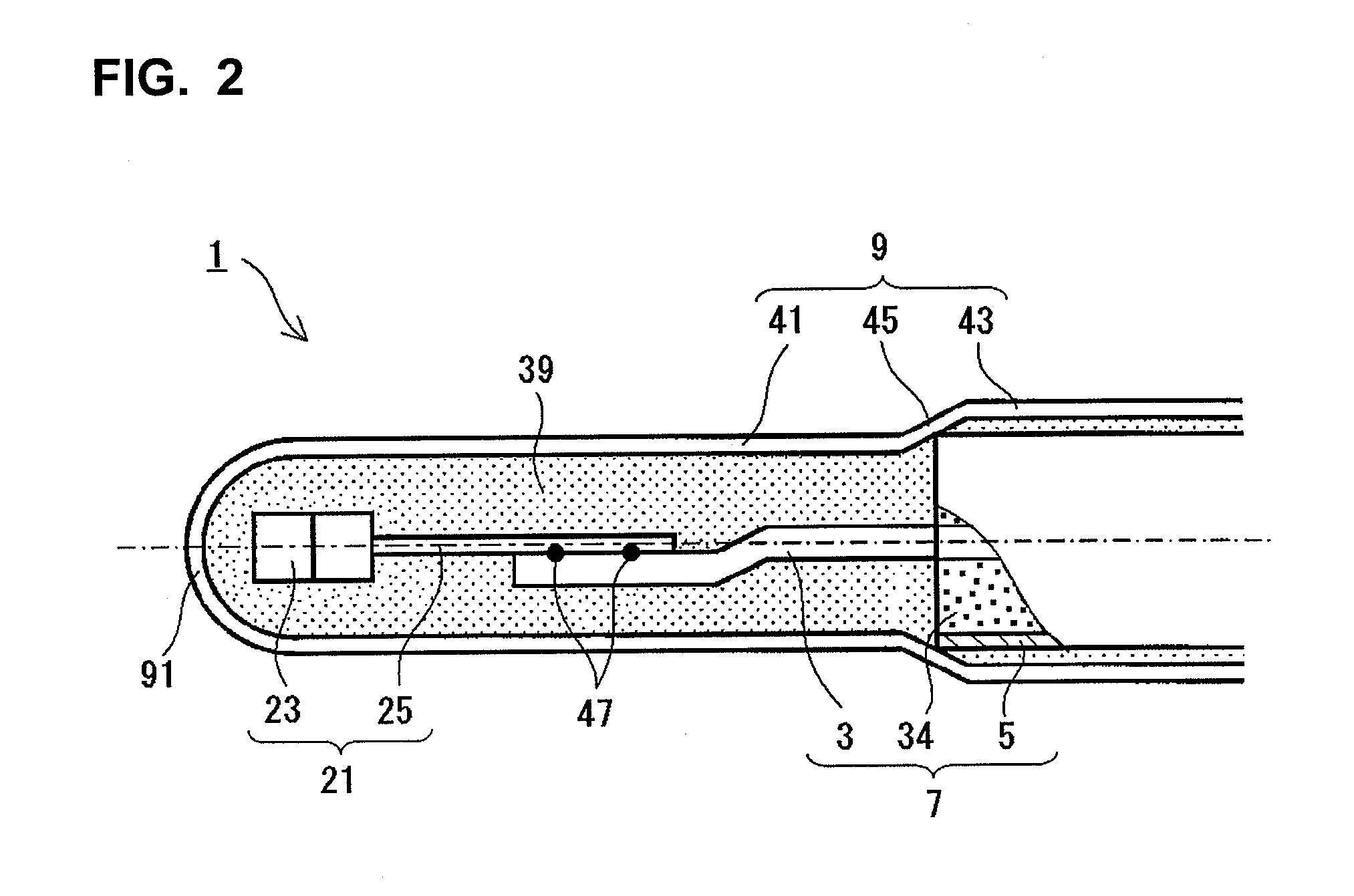

Temperature sensor

ActiveUS20090323765A1Improve solderabilityImprove welding strengthThermometer detailsThermometers using electric/magnetic elementsPlatinumStrontium

In a temperature sensor (1), a pair of electrode wires (25) of a thermistor element (21) are formed of a material prepared by adding strontium to platinum or a platinum alloy and without addition of zirconia or a like oxide. Rear end portions of the electrode wires (25) formed of the above-mentioned material and front end portions of sheath core wires (3) are laser-welded to one another in an overlapping condition.

Owner:NGK SPARK PLUG CO LTD

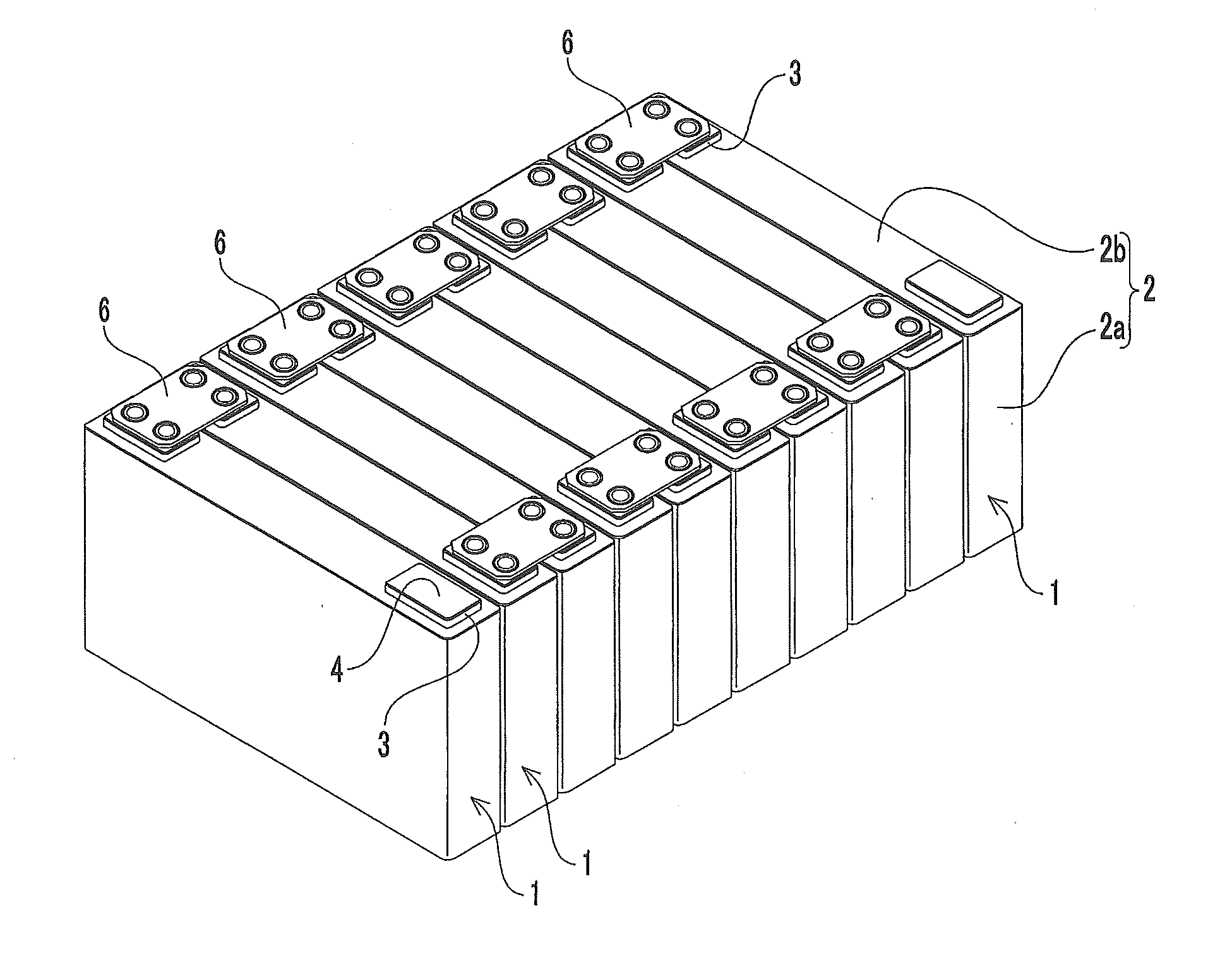

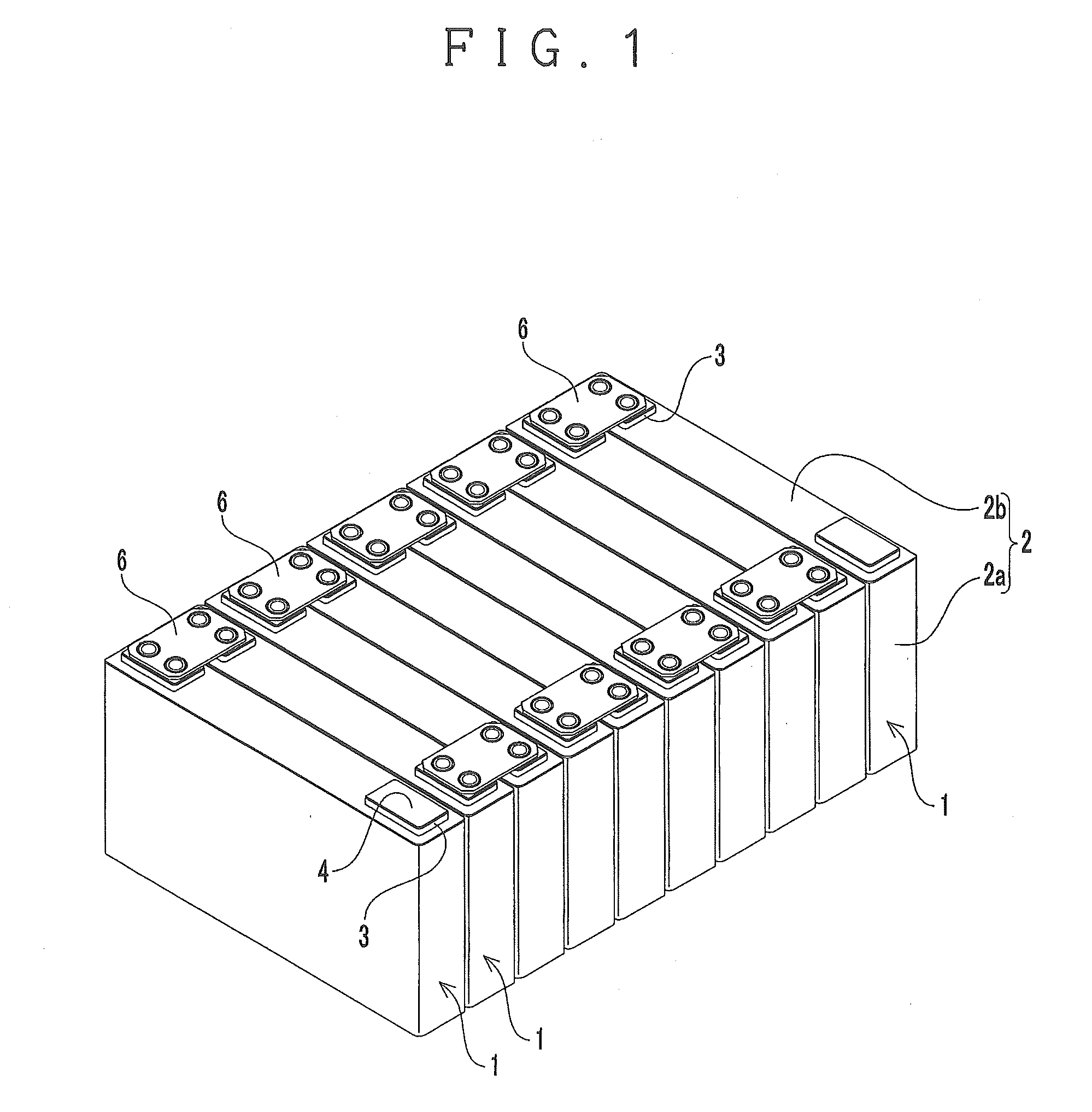

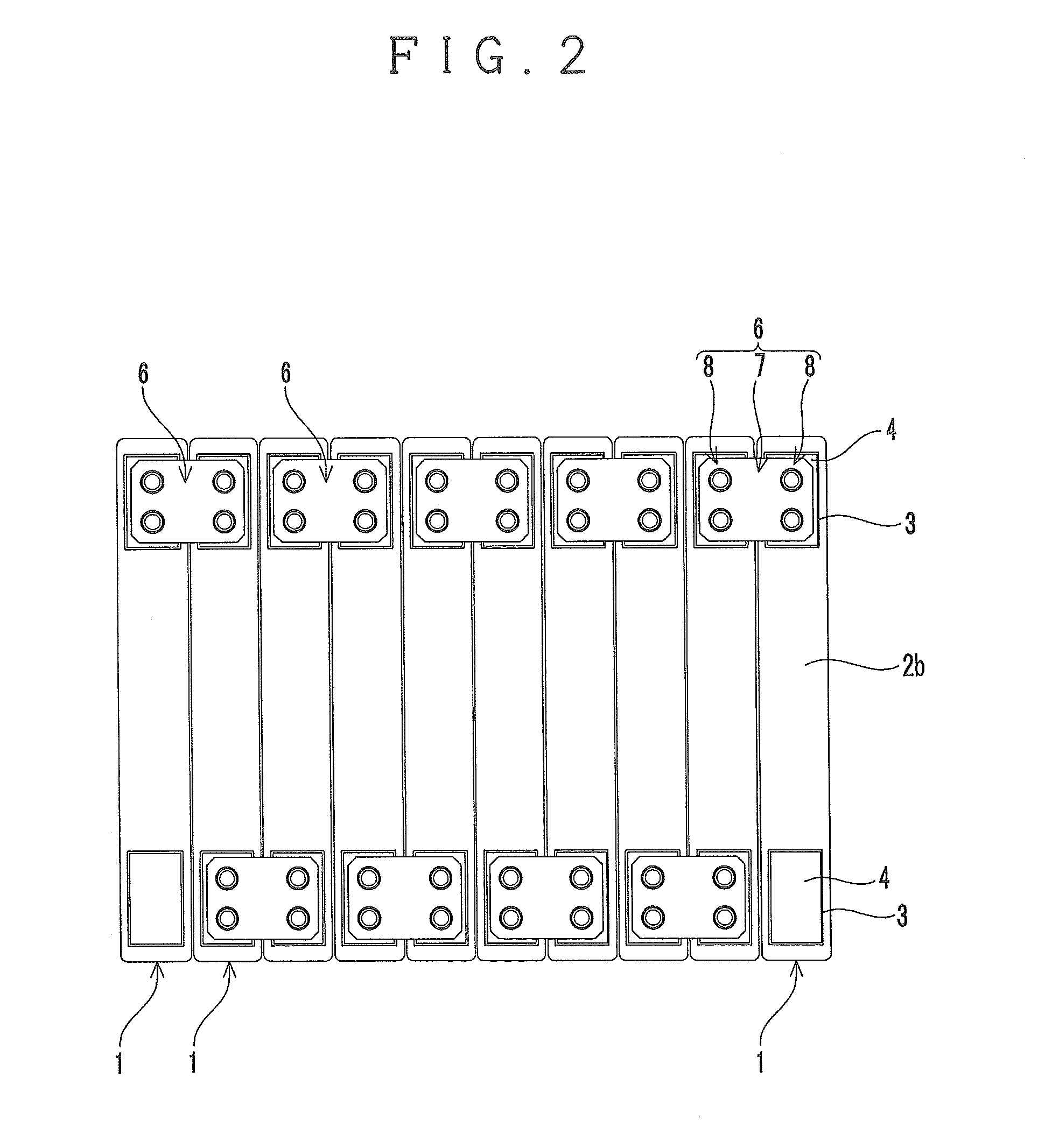

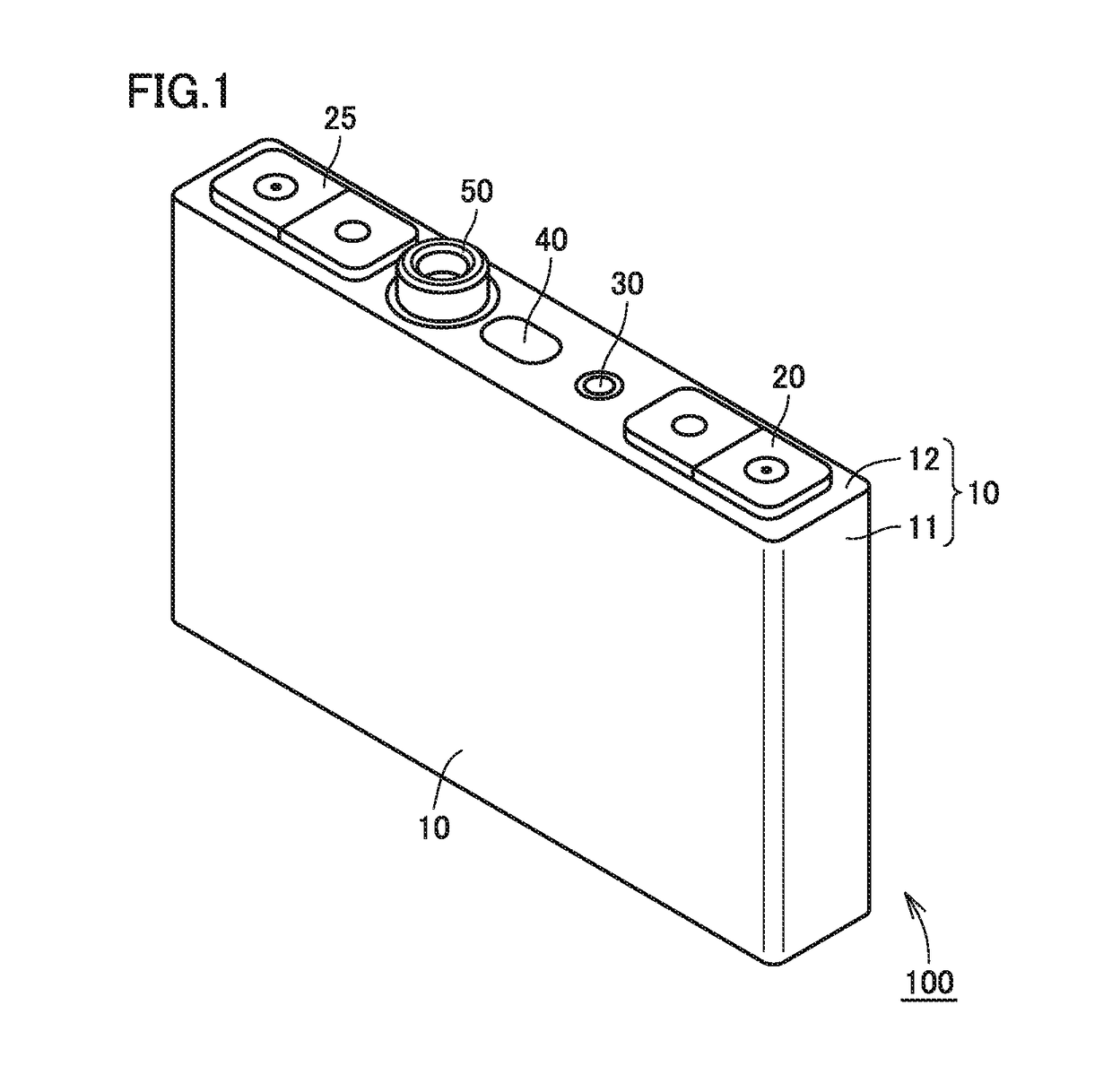

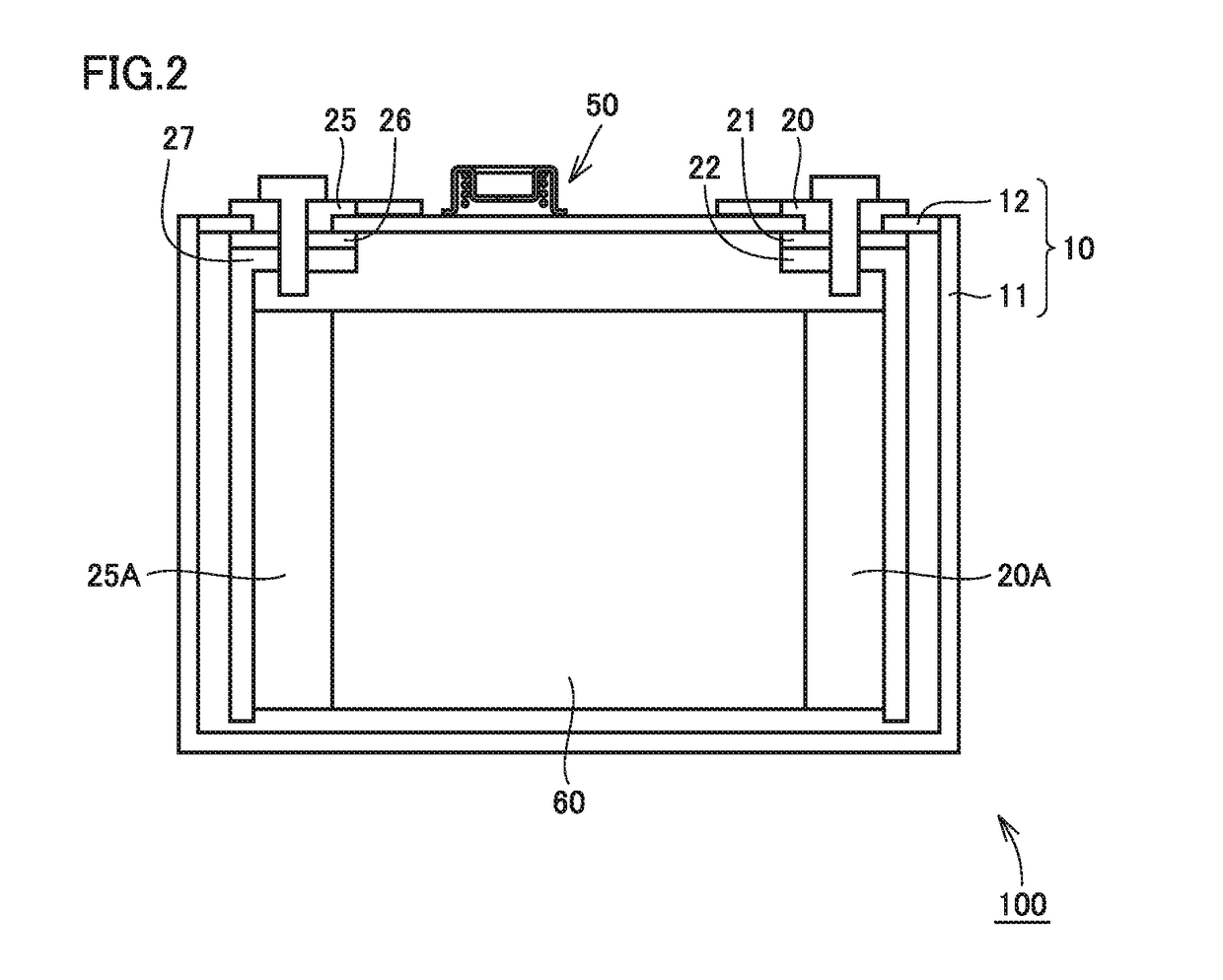

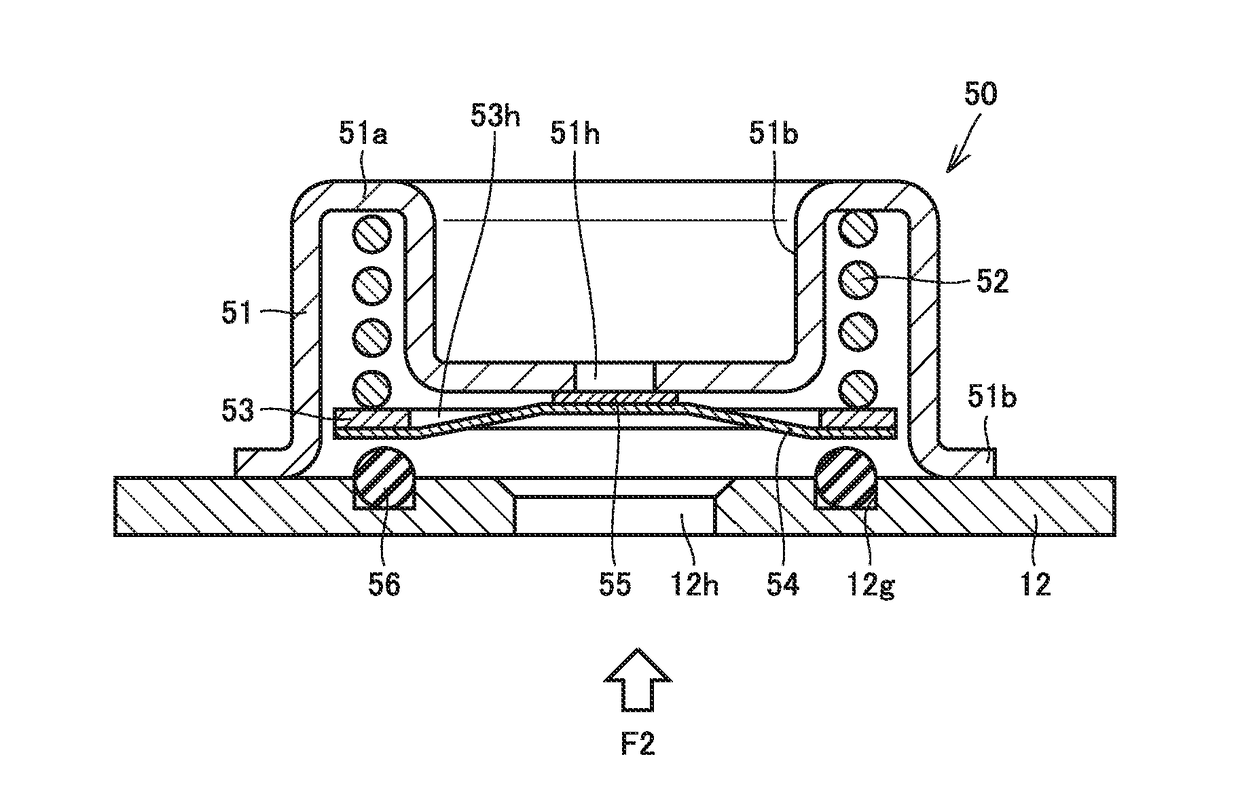

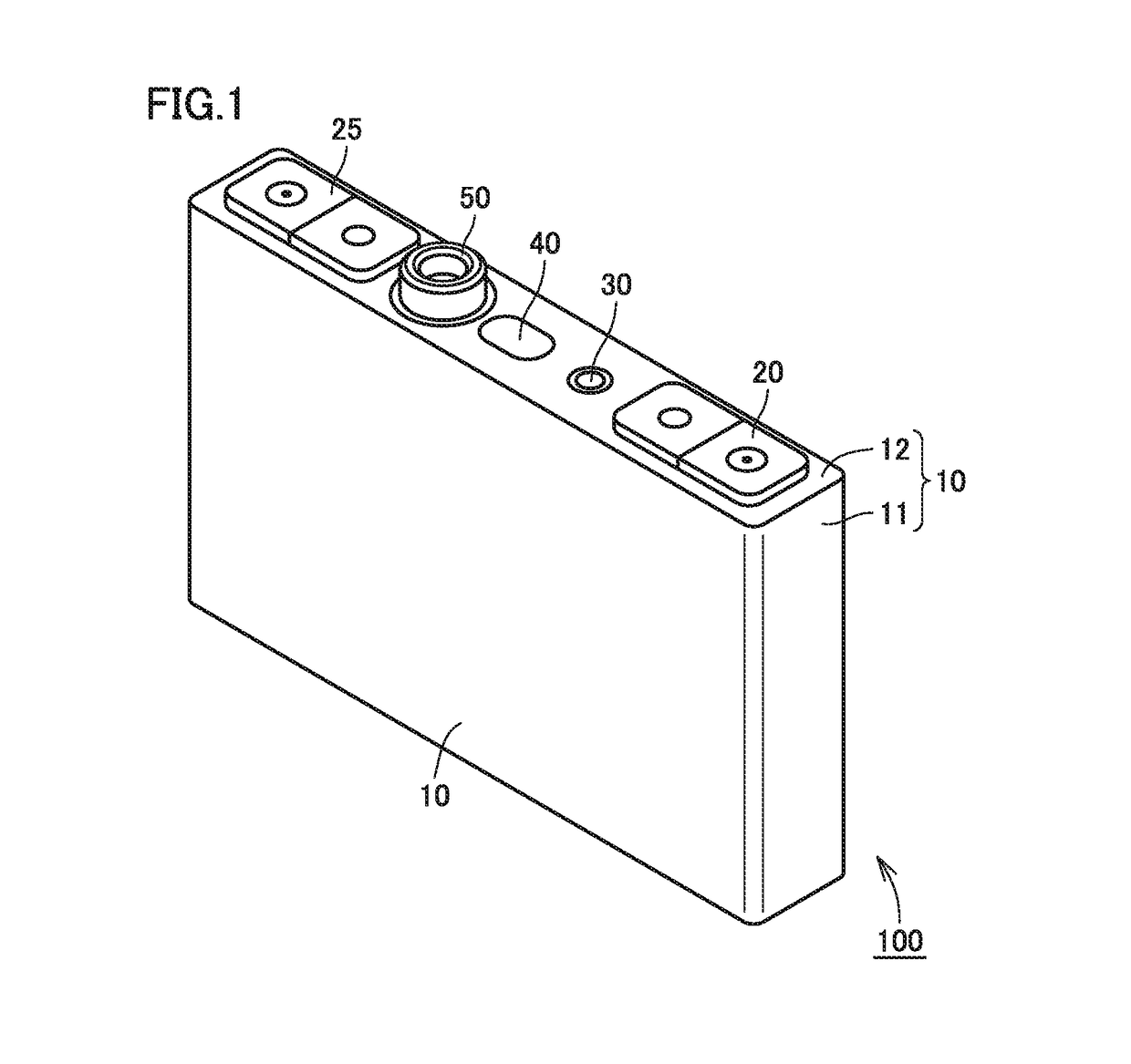

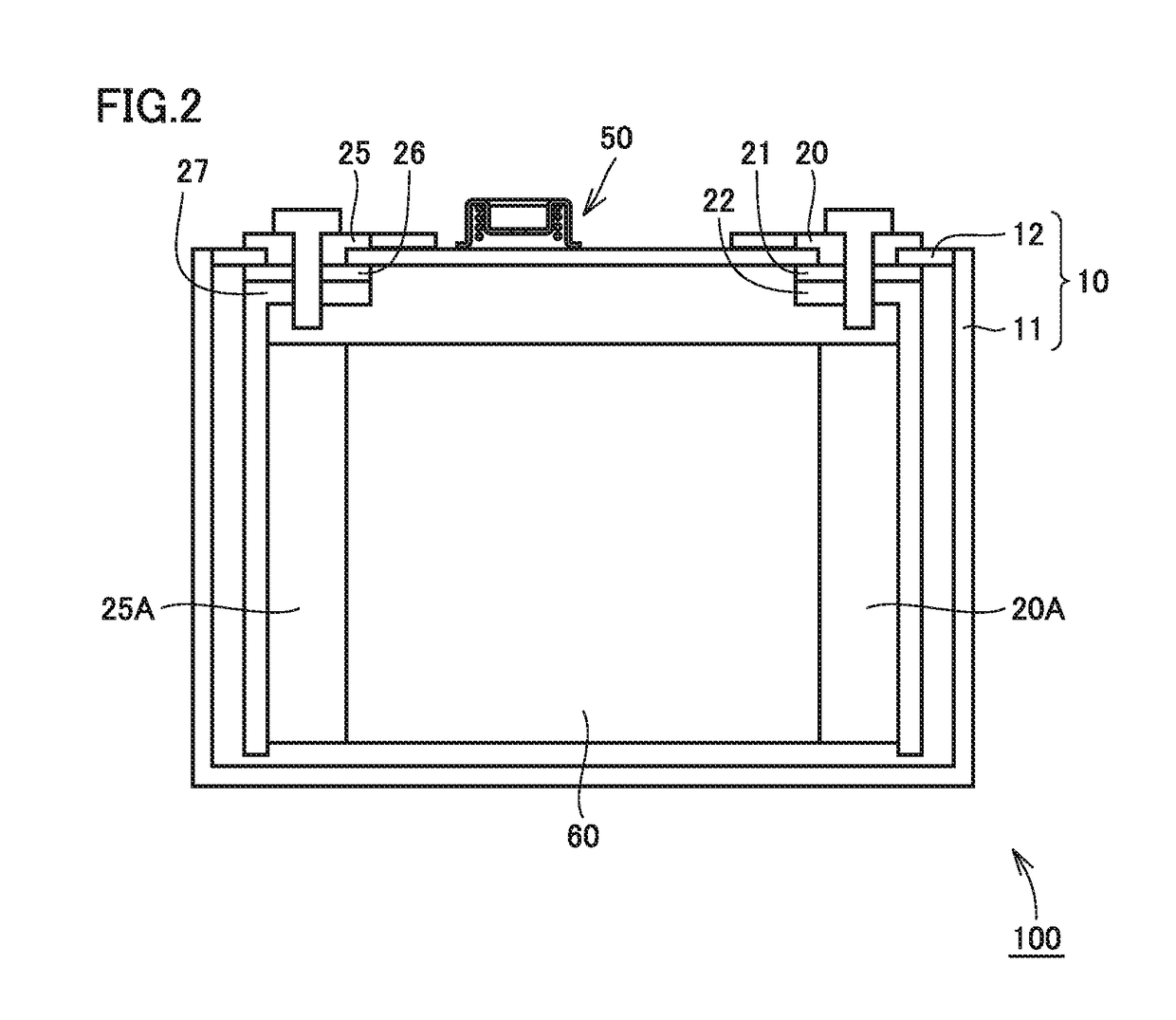

Electric storage apparatus and method for producing the electric storage apparatus

ActiveUS20140377625A1Reduce welding strengthReduced strengthSmall-sized cells cases/jacketsPrimary cellsElectrical and Electronics engineering

Provided is an electric storage apparatus including: an electric storage device including an external terminal that has a first connection surface; a bus bar having a second connection surface that overlaps the first connection surface; a first weld portion that is formed extending over the external terminal and the bus bar in a region where the first connection surface and the second connection surface are opposed to each other; and a second weld portion that is formed extending over the external terminal and the bus bar in a region where the first connection surface and the second connection surface are opposed to each other, the second weld portion overlapping the first weld portion, wherein the second weld portion is formed such that its weld center is displaced from a weld center of the first weld portion. Also provided is a method for producing the electric storage apparatus.

Owner:GS YUASA INT LTD

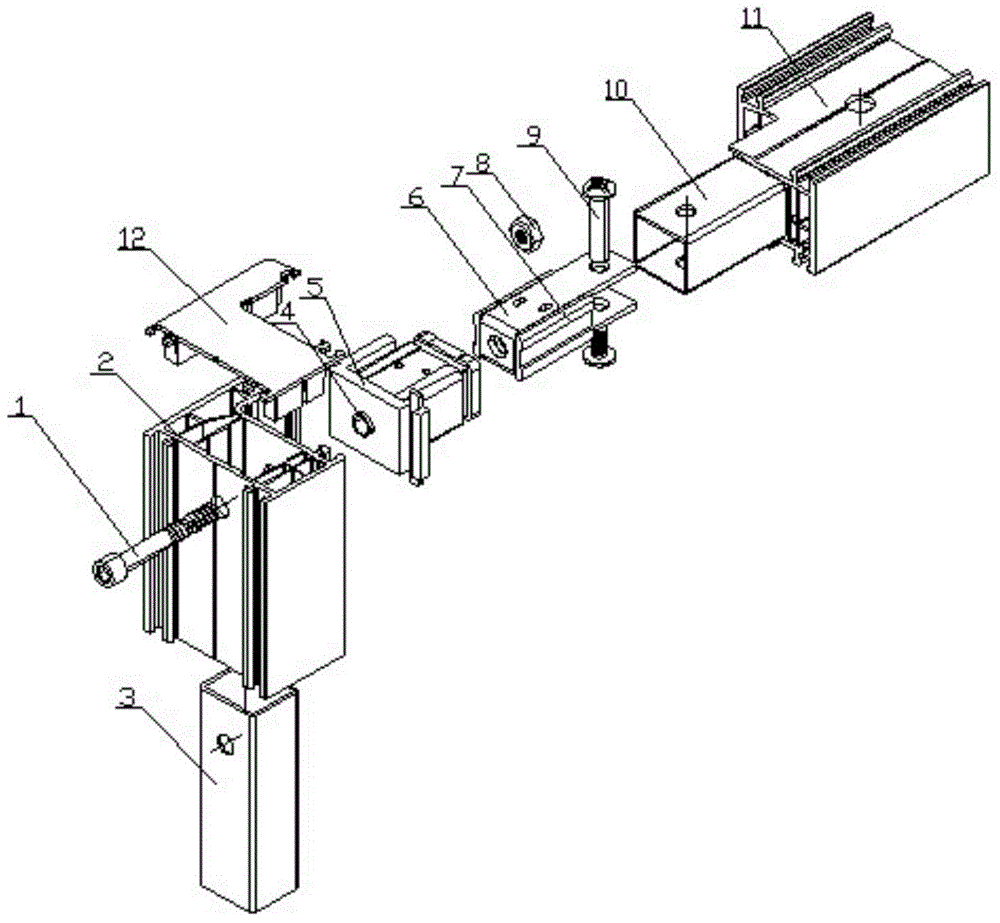

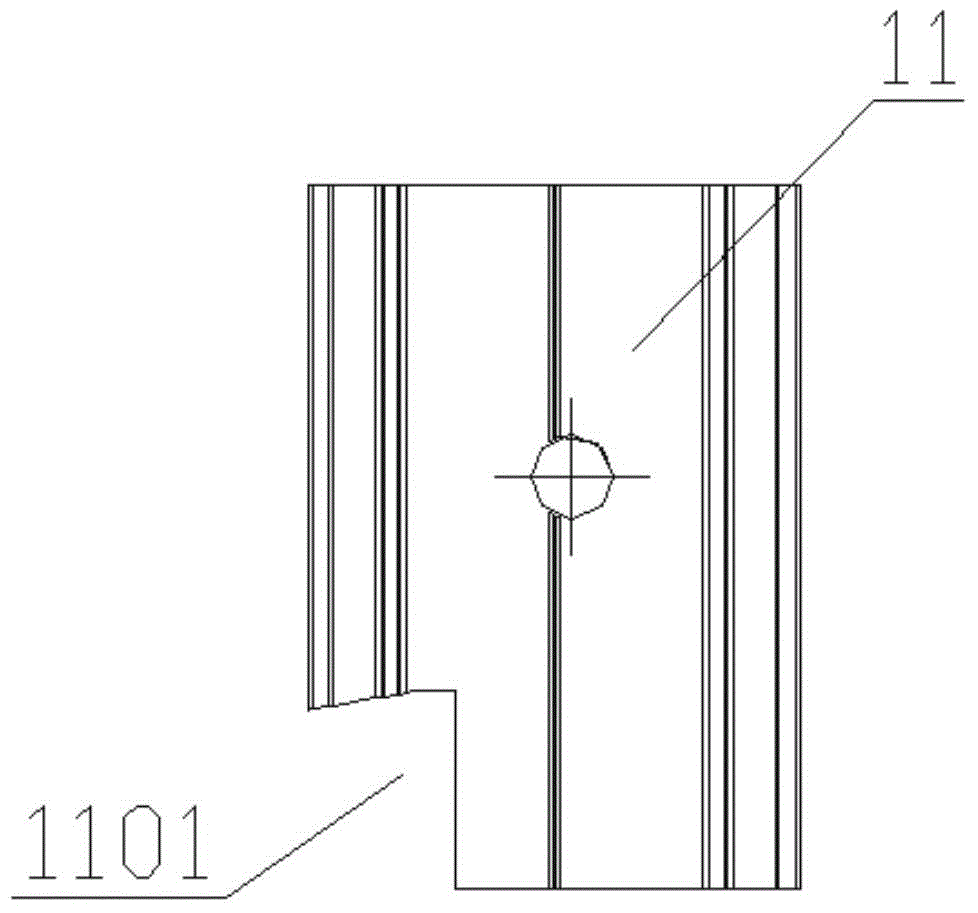

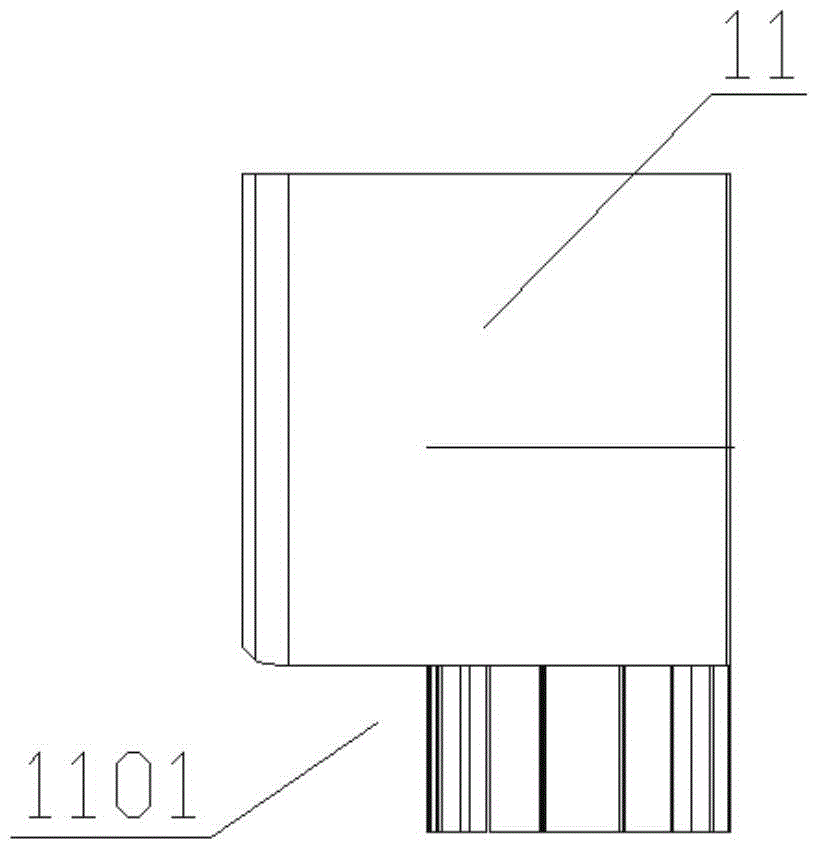

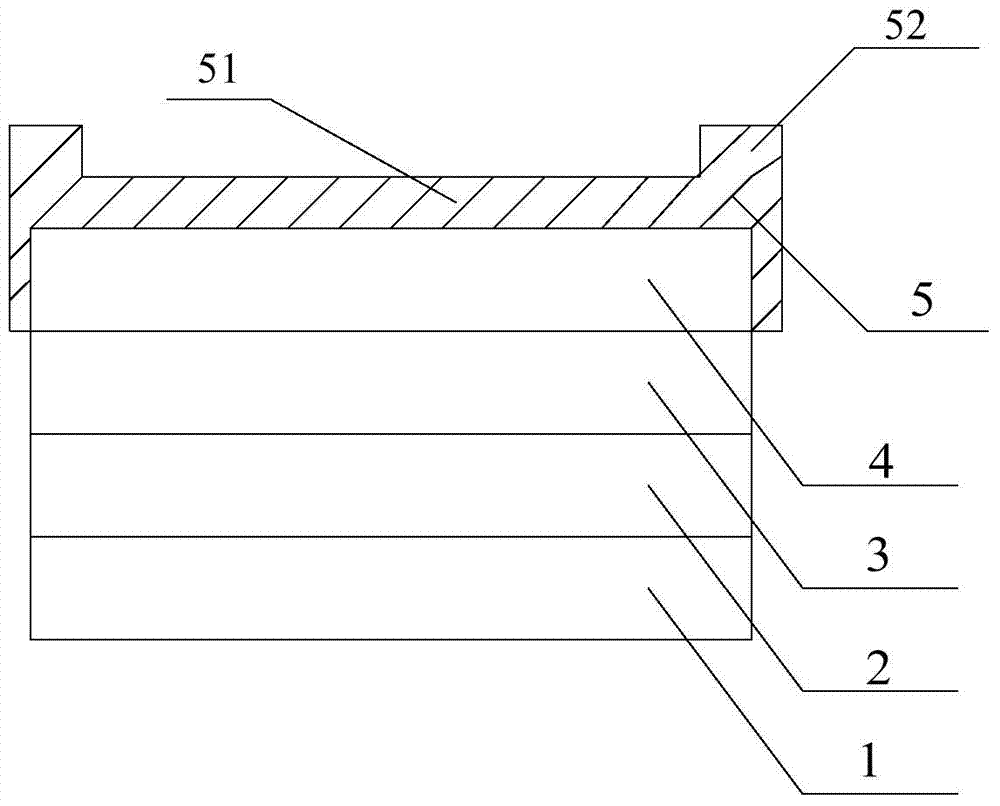

Right-angle screwing connection structure of plastic steel window frame and installing method thereof

ActiveCN103953267AImprove aestheticsBeautify the appearanceDoors/windowsSocial benefitsPhysical space

The invention relates to a right-angle screwing connection structure of a plastic steel window frame and an installing method of the right-angle screwing connection structure. The right-angle screwing connection structure comprises a first plastic steel sectional material, a second plastic steel sectional material and a connecting element, wherein the first plastic steel sectional material and the second plastic steel sectional material are mutually vertical, the connecting element comprises an outer sheathing element, an inner embedding element and a steel inserting element, and the first plastic steel sectional material and the second plastic steel sectional material are fixedly and vertically connected into a whole through the connecting element. The right-angle screwing connection structure of the plastic steel window frame has the advantages that the connecting element is adopted at a connecting part of the window frame for realizing the combination and connection, the traditional welding mode is completely replaced, on one hand, the occurrence of aggregation is eliminated, the appearance effect of the plastic steel window frame is beautified, on the other hand, the plastic steel window frame can be combined and dismounted, in a special application scene, the plastic steel window frame can be dismounted for replacing the occupied physical space, and the transportation, the loading and the unloading are convenient. Meanwhile, the right-angle screwing connection structure of the plastic steel window frame has the advantages that the installation is convenient, the processing process is simple, the manufacturing and production cost is low, the effect is good, obvious social benefits and economic benefits are realized, and the right-angle screwing connection structure of the plastic steel window frame is worth of being popularized and applied.

Owner:VIEWMAX DOORS & WINDOWS CO LTD

Temperature sensor

ActiveUS8702305B2Strength of electrode wiresReduce welding strengthThermometer detailsCurrent responsive resistorsPlatinumStrontium

In a temperature sensor (1), a pair of electrode wires (25) of a thermistor element (21) are formed of a material prepared by adding strontium to platinum or a platinum alloy and without addition of zirconia or a like oxide. Rear end portions of the electrode wires (25) formed of the above-mentioned material and front end portions of sheath core wires (3) are laser-welded to one another in an overlapping condition.

Owner:NGK SPARK PLUG CO LTD

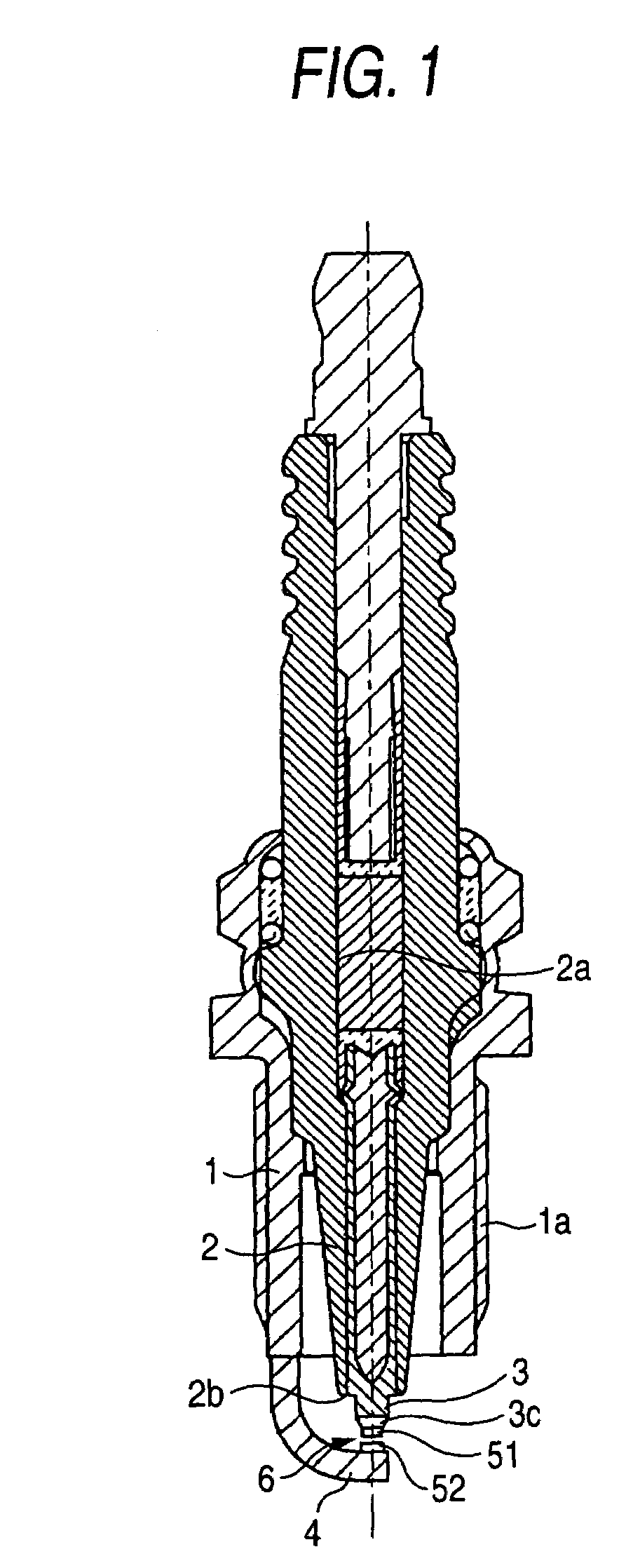

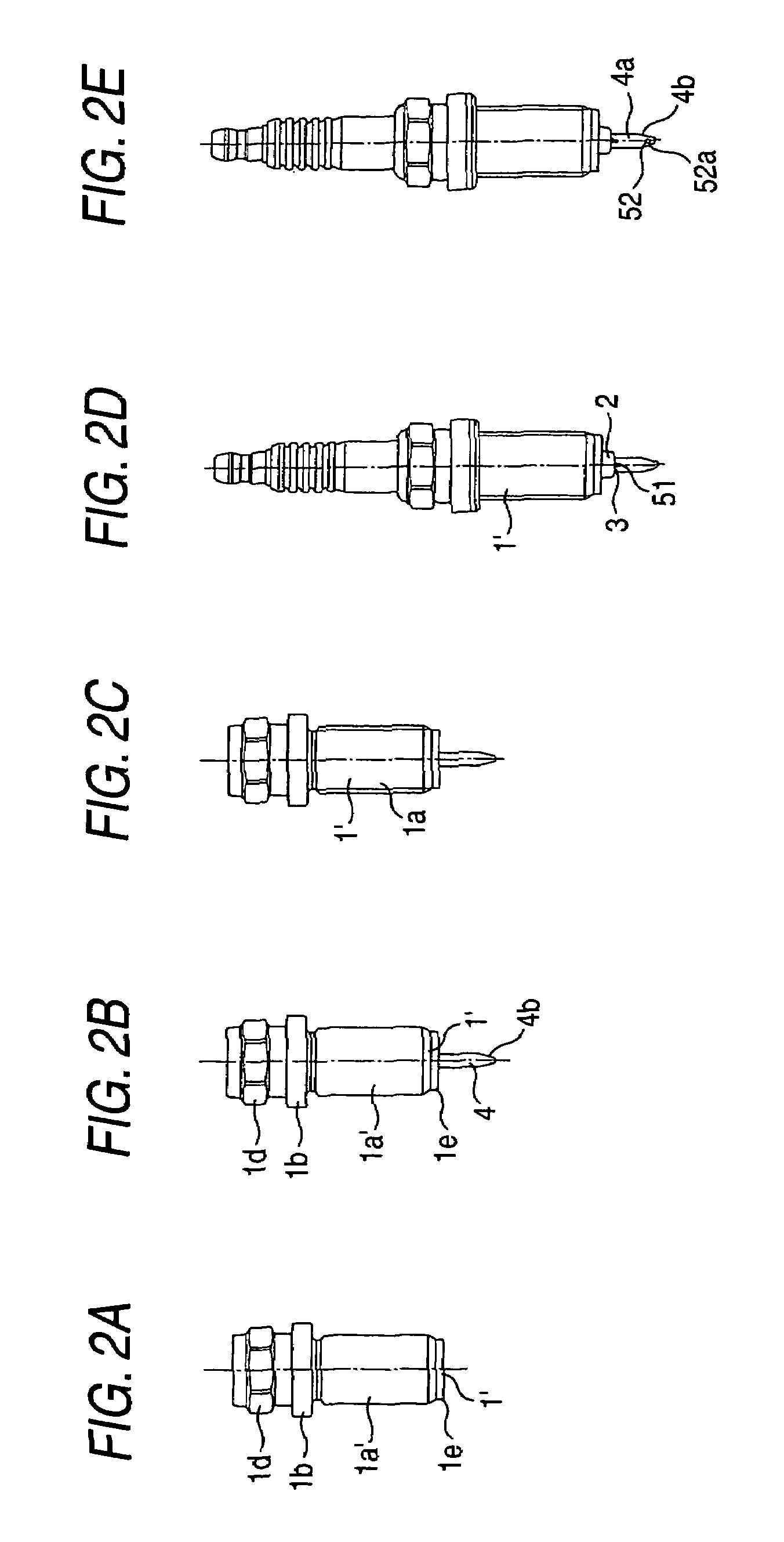

Spark plug having a specific structure of noble metal tip on ground electrode

A method for producing a spark plug, the spark plug including: a center electrode; an insulator which holds the center electrode therein in a state where a tip end portion of the center electrode protrudes therefrom; a metal shell which holds the insulator therein; a ground electrode which is fixed to the metal shell, the ground electrode having an inner side face having a width that is smaller as it advances toward a tip end side, in a portion of the inner side face positioned between a pair of tapered faces; and a discharge portion which is bonded to the inner side face of the ground electrode by laser welding so as to attain a diameter of 0.8 mm or less and a height of 0.5 mm or more, a discharge gap being formed between the discharge portion and the tip end portion of said center electrode, the method including: forming the tapered faces before the discharge portion is laser-welded to the inner side face.

Owner:NGK SPARK PLUG CO LTD

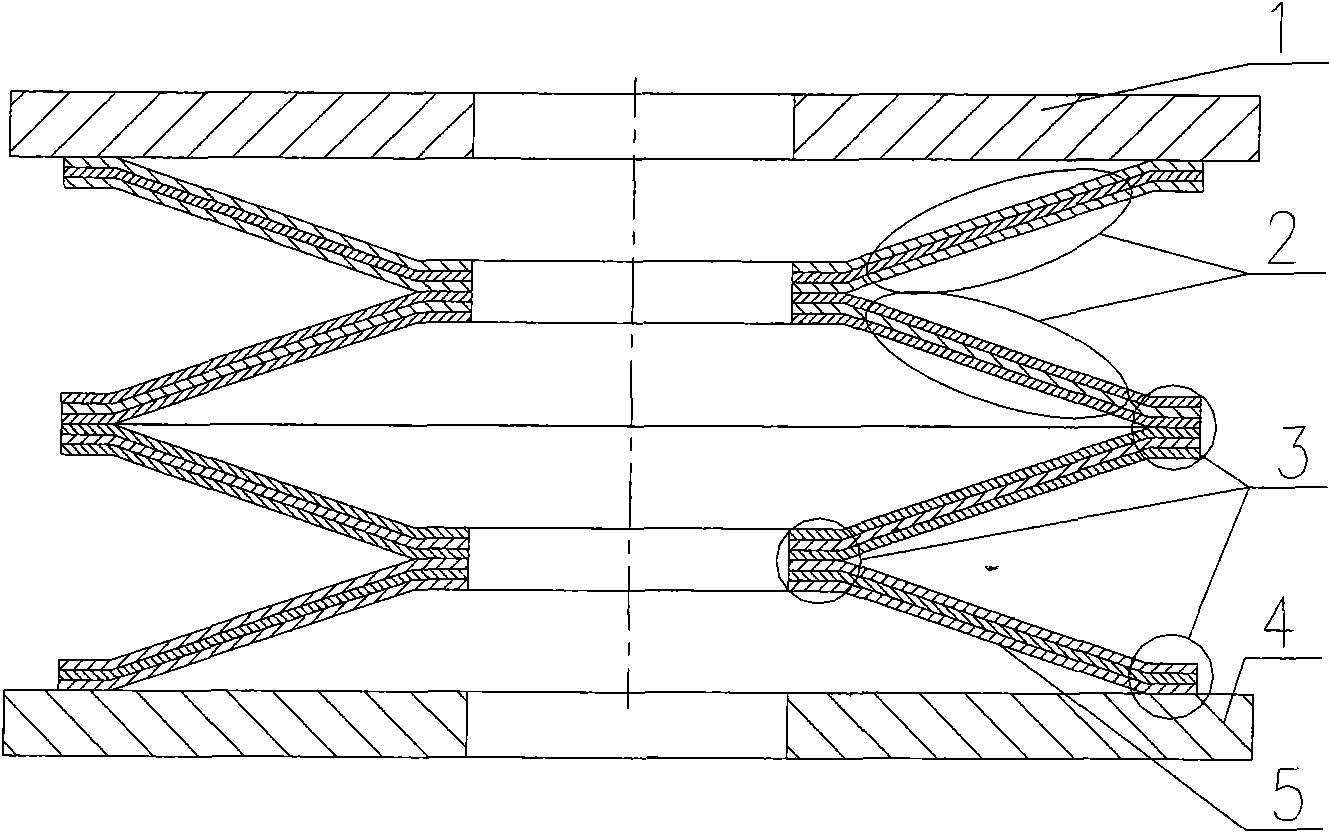

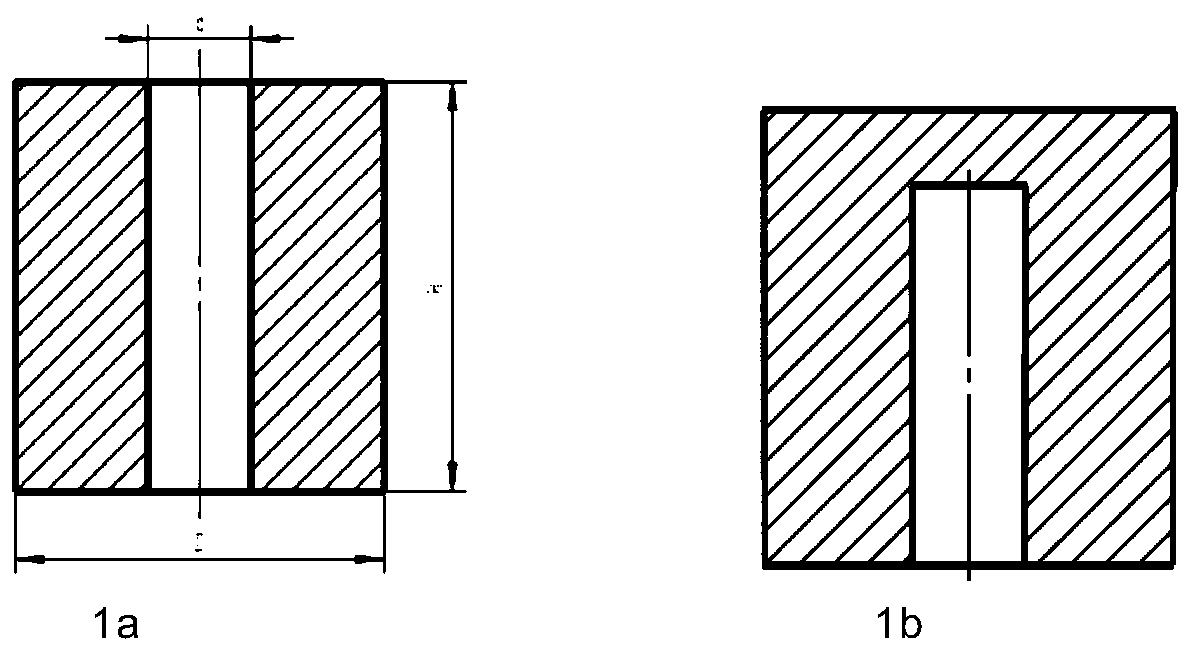

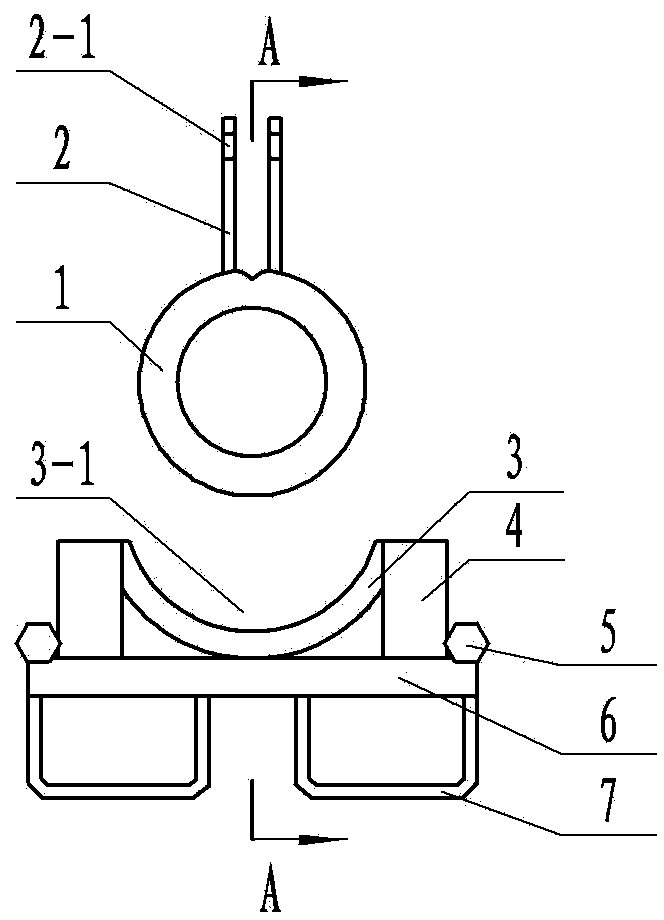

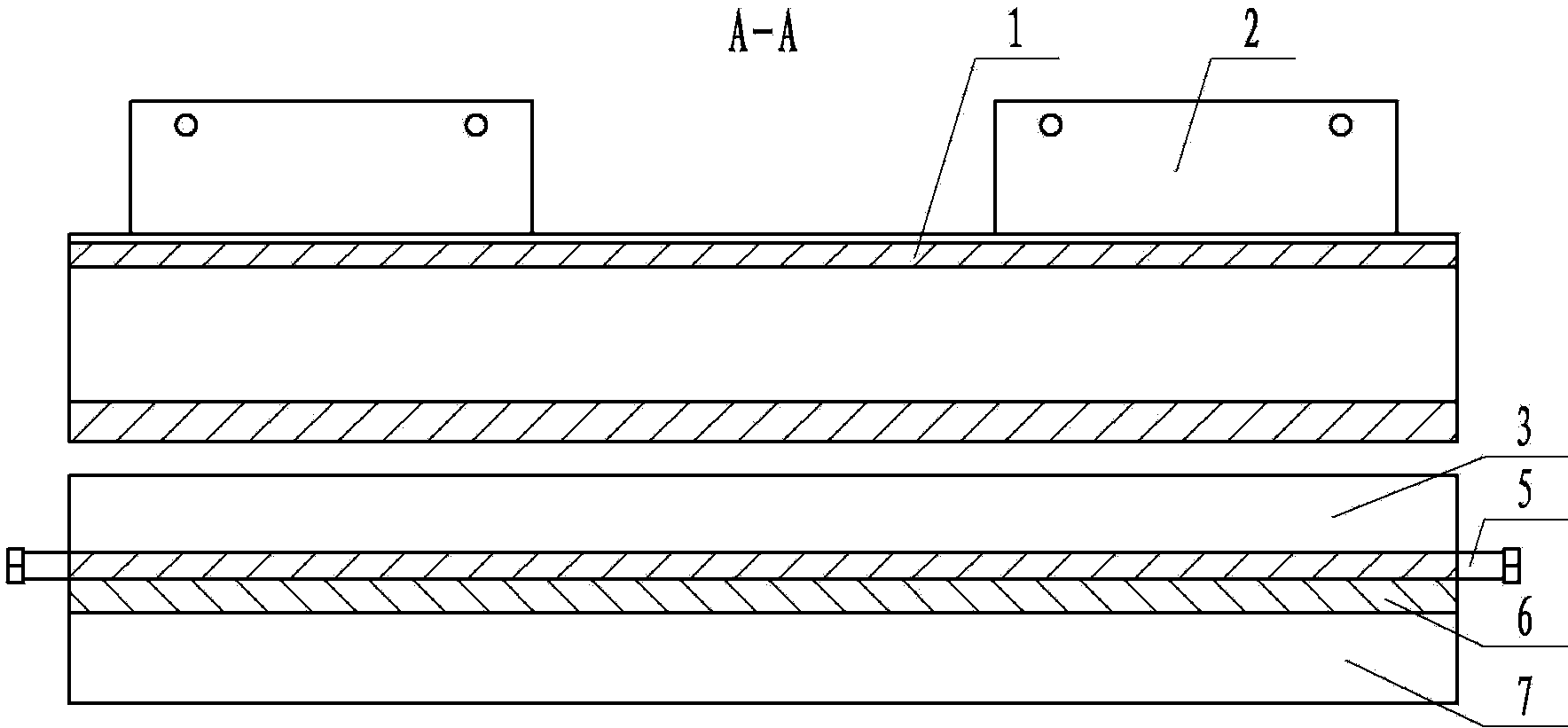

Diffusion welding multilayer structure diaphragm capsule

The invention is a diffusion welding multilayer structure diaphragm capsule, belonging to the field of diaphragm capsule manufacturing. By adopting the methods of diffusion welding, machining and shaping, the manufacturing of diaphragm capsule in the invention can be realized. The main procedures include thin wall blank preparation, surface cleaning, surface modified treatment, welding-stopping treatment, diffusion welding, machining, shaping and the like. Compared with the multilayer structure diaphragm capsule manufactured by other methods, the multilayer structure diaphragm capsule manufactured by the invention has the advantages of fine fatigue property (above 1 million times), strong pressurization performance, adjustable rigidity, high compression ratio (higher than 80%), capability of micromation of inner holes, high precision of geometric dimensions, strong destabilization resistance, precise and controllable weldingline profile, adjustable width of weldingline and the like. By using the invention, the diaphragm capsule in the shape of circle, square and other shapes can be manufactured, and can serve as a compensation element of displacement and angle in hydraulic, barometric, transferring pipeline installation, an elastic compensation element and a pore damping element as well as a measuring element for a manometer and an altimeter; besides, the diaphragm capsule can be also used as a heat transferring finned tube for air conditioning, refrigeration and other devices as well as a metal capsule of separating gas or liquid for an accumulator and a storage box. The invention can provide multilayer structure diaphragm capsule products with fine performance for related industries.

Owner:北京智创联合科技股份有限公司

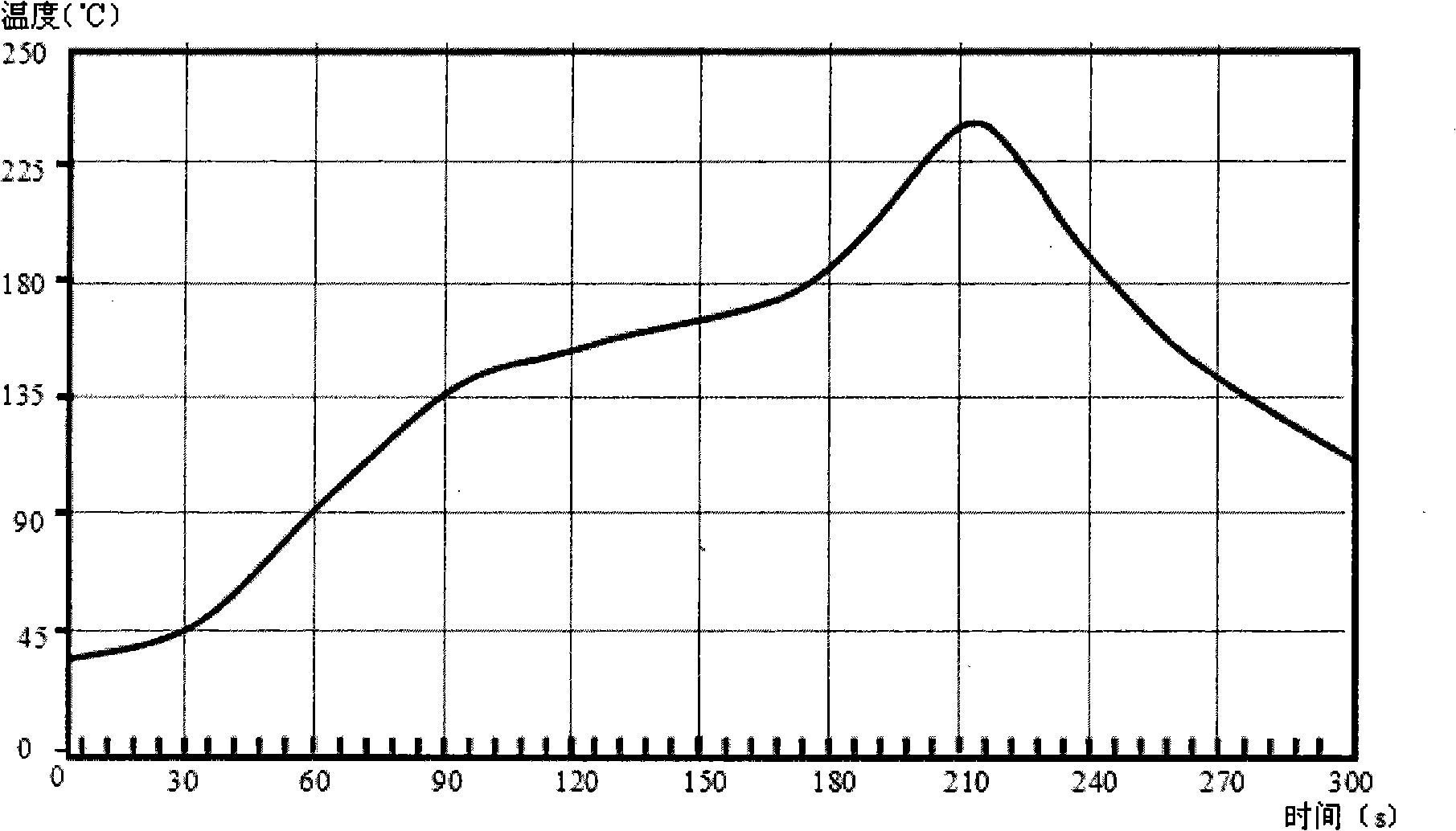

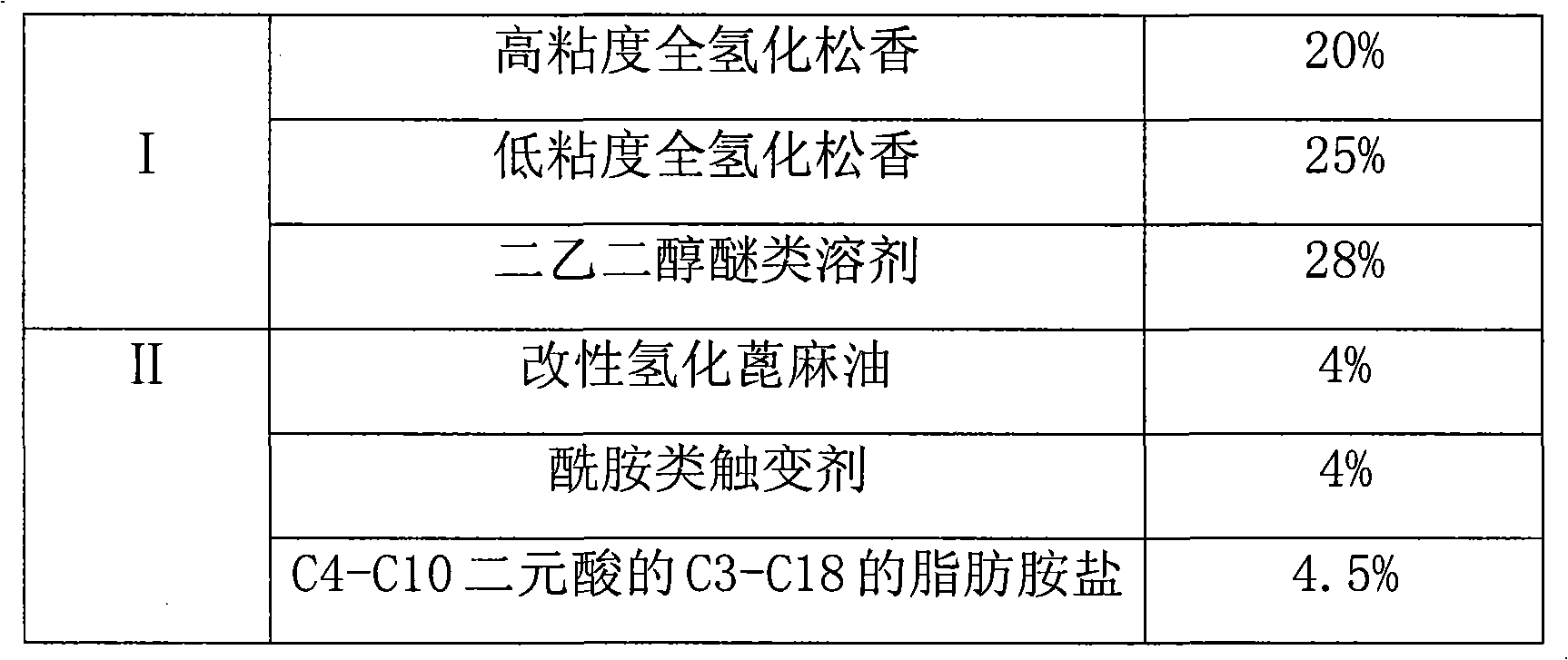

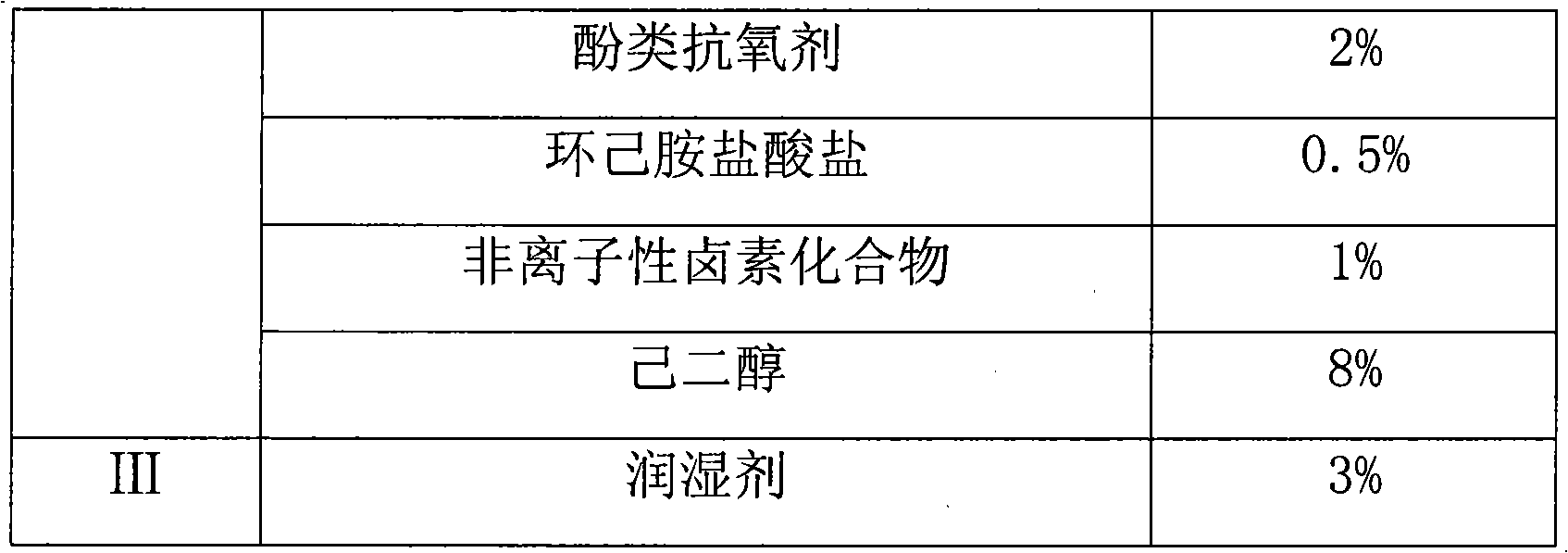

Middle-temperature energy-saving leadless solder paste special for tuners

InactiveCN101347875AReduce welding strengthAvoid damageWelding/cutting media/materialsSoldering mediaFatty amineAlloy

The invention aims at solving the problems of the lead-free solder paste used in the production of tuners such as rosin joint, excessive residual solder beadings after welding and easy shedding of welding spots which are likely to happen in production, and provides a medium-temperature energy-saving lead-free solder paste specially used for tuners; the medium-temperature energy-saving lead-free solder paste is composed of Sn64Bi35Ag1 alloy solder powder and soldering flux paste; the soldering flux paste contains the components with the following weight percentage: 20-30% of high-viscosity perhydrogenated rosin, 20-25% of low-viscosity perhydrogenated rosin, 4-6% of modified hydrogenated castor oil, 2-4% of acid amide thixotropic agent, 4-6% of C3-C18 fatty amine salt of C4-C10 dibasic acid, 2-3% of phenolic antioxidant, 0.5-01.0% of cyclohexylamine hydrochloride, 1-2% of non-ionic halogen compound, 8-10% of hexamethylene glycol, 3-5% of wetting agent and 23-28% of diethylene glycol solvent. The medium-temperature energy-saving lead-free solder paste can effectively prevent the shedding phenomena of solder paste, has no solder beadings in products, little and transparent residue after welding, good insulating property, no-clean property and extremely strong postwelding reliability, and can reduce the heat shock damage to components and circuit boards and lower power consumption by about 8-10% at the same time.

Owner:深圳市贝壳能源科技有限公司

Method for manufacturing metal parts and molds and micro-roller used therefor

ActiveUS9302338B2Formability of complexImprove accuracyArc welding apparatusAdditive manufacturing with liquidsNumerical controlGradient material

A method for manufacturing parts and molds by: 1) slicing a three-dimensional CAD model of a part or mold; 2) planning a modeling path according to slicing data of the three-dimensional CAD model, whereby generating numerical control codes for modeling processing; and 3) performing fused deposition modeling of powders or wire material of metal, intermetallic compounds, ceramic and composite functional gradient materials by layer using a welding gun on a substrate layer via a numerical control gas shielded welding beam or laser beam according to a track specified by the numerical control code for each layer. A micro-roller or a micro-extrusion unit is installed at a contact area between melted and softened areas. The micro-roller or the micro-extrusion unit synchronously moves along with fused deposition area, which results in compressing and processing of the fused deposition area during the fused deposition modeling.

Owner:HUAZHONG UNIV OF SCI & TECH

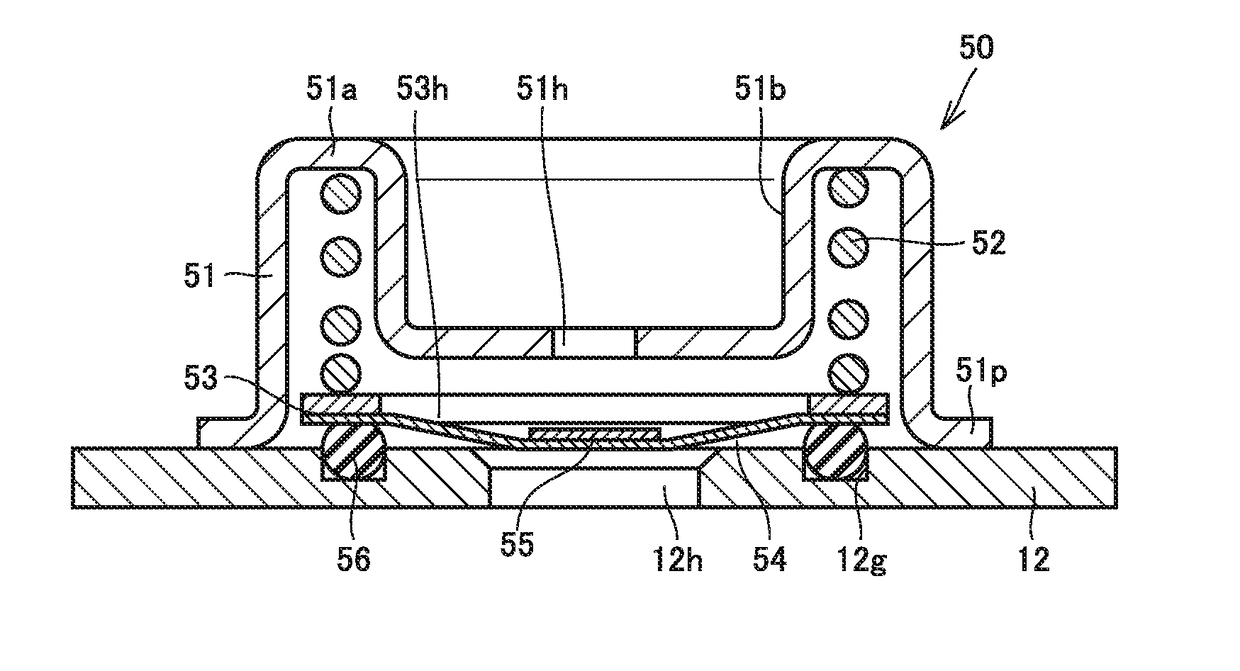

Sealed battery

ActiveUS20170098807A1Improve securityReduce welding strengthSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsInternal pressureClosed state

A sealed battery with a battery element housed in a sealed casing. The sealed battery includes a valve brought into a closed state when a pressure of a gas in the casing is less than a first pressure P1, into an open state when the pressure is more than or equal to the first pressure P1 and less than a second pressure P2, and into the closed state when the pressure is more than or equal to the second pressure P2, and a safety mechanism configured to, when the internal pressure reaches a third pressure P3 exceeding the second pressure P2, operate in accordance with the third pressure P3.

Owner:TOYOTA JIDOSHA KK

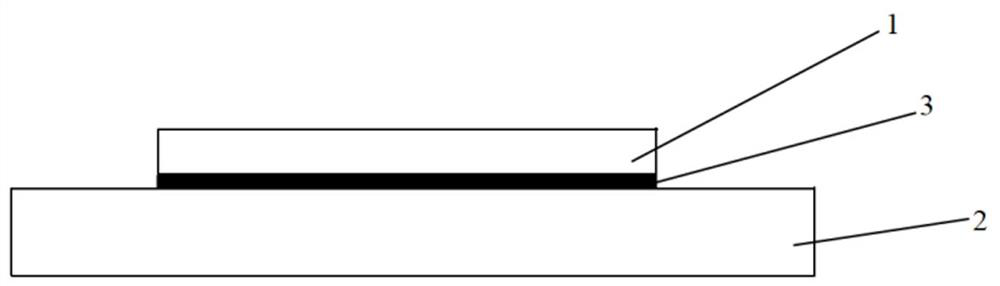

Solar cell slice and fabrication method thereof

InactiveCN104078519AReduce widthReduced series resistanceFinal product manufacturePhotovoltaic energy generationFill factorEngineering

The invention provides a solar cell slice and a fabrication method thereof. The solar cell slice comprises a silicon substrate slice, a positive-surface electrode on the front surface of the silicon substrate slice, a back electric field on the back surface of the silicon substrate and a back electrode electrically communicated with the back electric field, wherein the front surface of the silicon substrate slice comprises a non-antireflection film region, and the positive-surface electrode comprises a metal titanium layer arranged on the surface of the non-antireflection film region and a conductive metal layer arranged on the surface of the metal titanium layer. The positive-surface electrode is high in fine density, line broken is difficult to happen, the solar cell slice is difficult to strip and fall off, the resistance when the cells are connected in series is low, high fill factor is achieved, the photoelectric conversion efficiency of the cell is high, and the cost is low.

Owner:BYD CO LTD

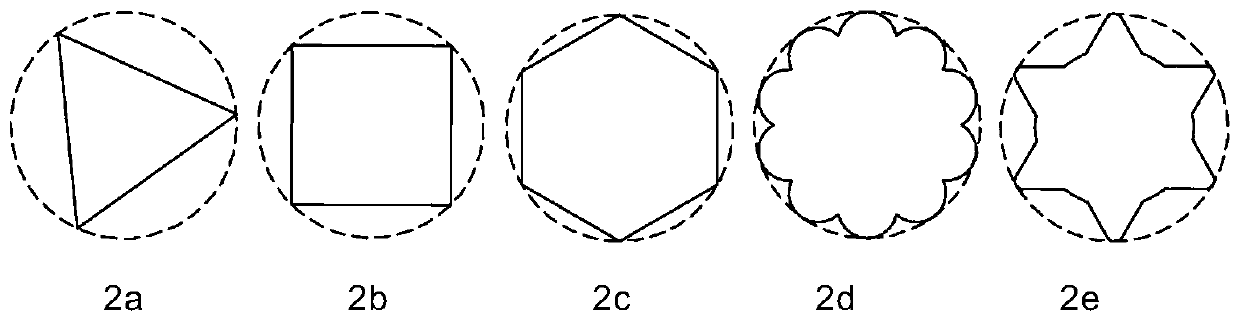

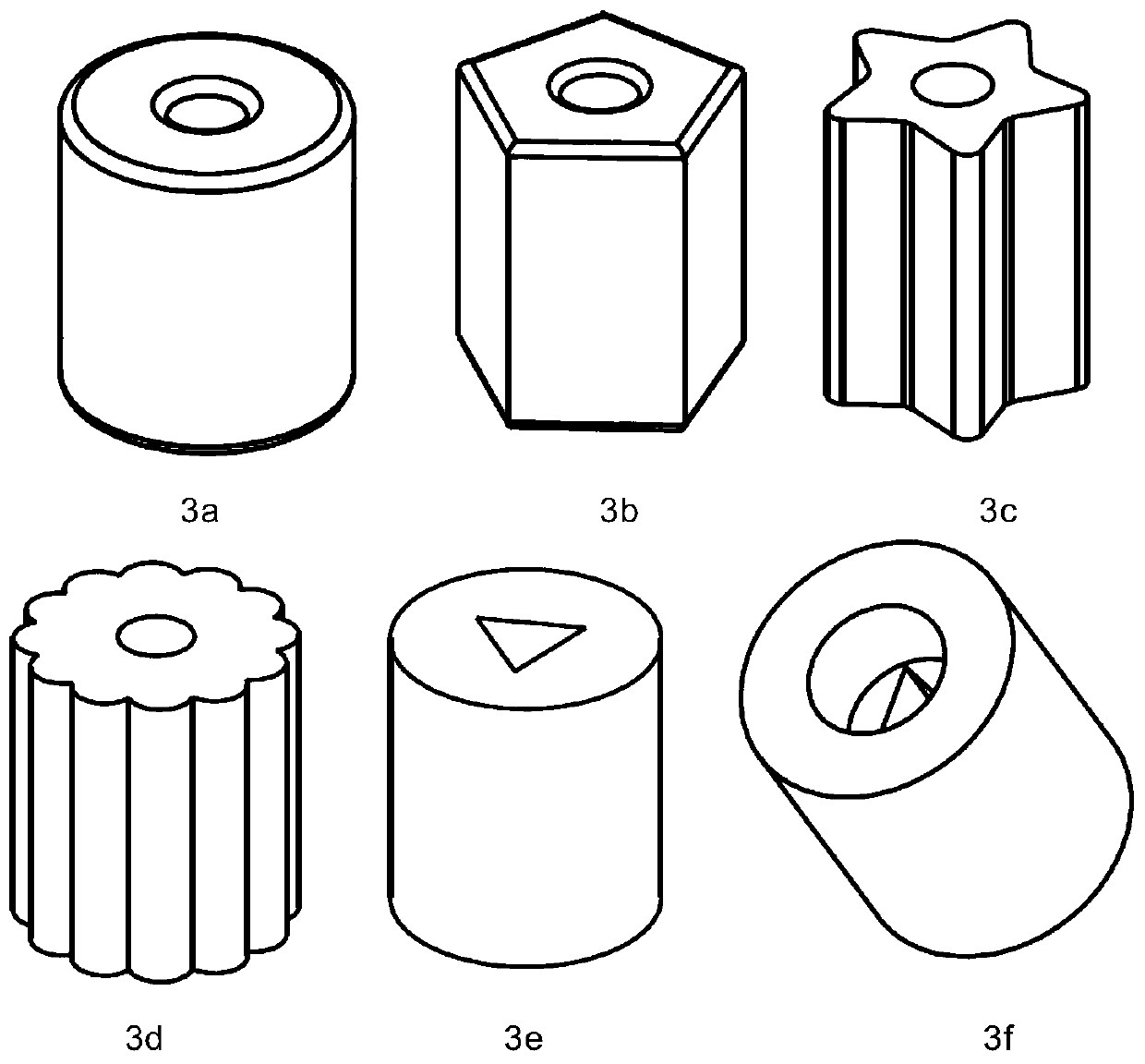

Perforated gas producing agent molding pressing product and preparation process thereof

PendingCN109809953AAdjust the burning surfaceSmall impactExplosivesPressure gas generationProcess engineeringIntermediate stage

The invention relates to a perforated gas producing agent molding pressing product and a preparation process thereof. The appearance of the perforated gas producing agent molding pressing product is acylinder body; a penetrated or non-penetrated hole is formed at the inside; the perforated gas producing agent can achieve the goals of reducing the surface combustion process, or realizing the equalsurface combustion or increased surface combustion in a period time in the combustion process, and thus realizing the low early stage pressure and slope of the gas generator; the impact on an airbagand the harm are small; an airbag is slowly unfolded; the middle stage pressure fast rises; the airbag is fast filled; the later stage pressure is slowly reduced; the airbag maintaining time is prolonged; the curve is similar to the S-shaped pressure-time curve. The initial combustion surface is reduced; the reduced surface combustion or equal surface combustion or increased surface combustion arereduced; the pressure inside the gas generator is reduced, so that the material cost of the gas generator and the quality of the generator can be reduced. The pressing shaping process is used; the perforated gas producing agent is prepared in a pressing forming way, so that the preparation process is simple and efficient; the operation and the control are easy.

Owner:HUBEI HANGPENG CHEM POWER TECH

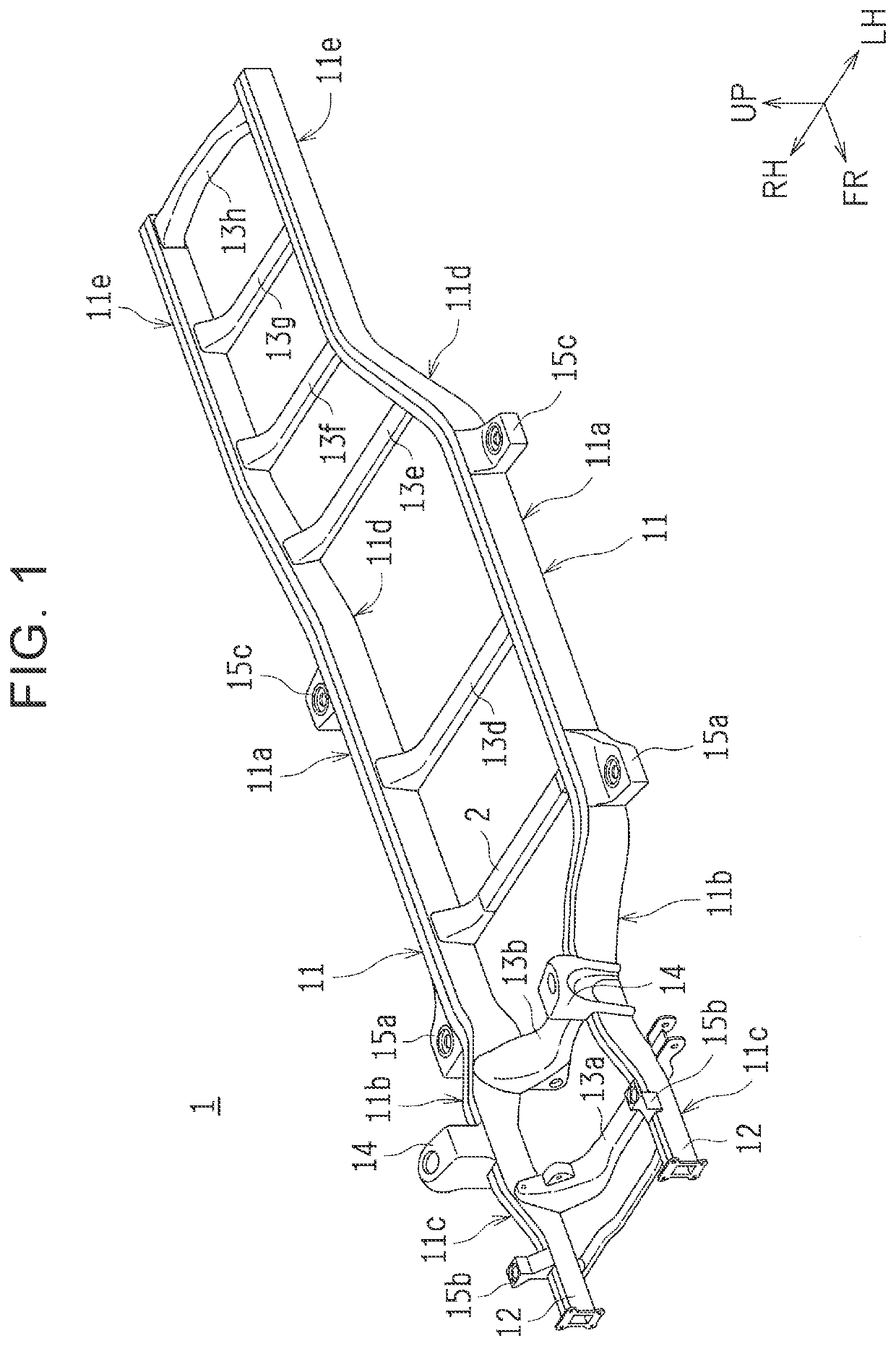

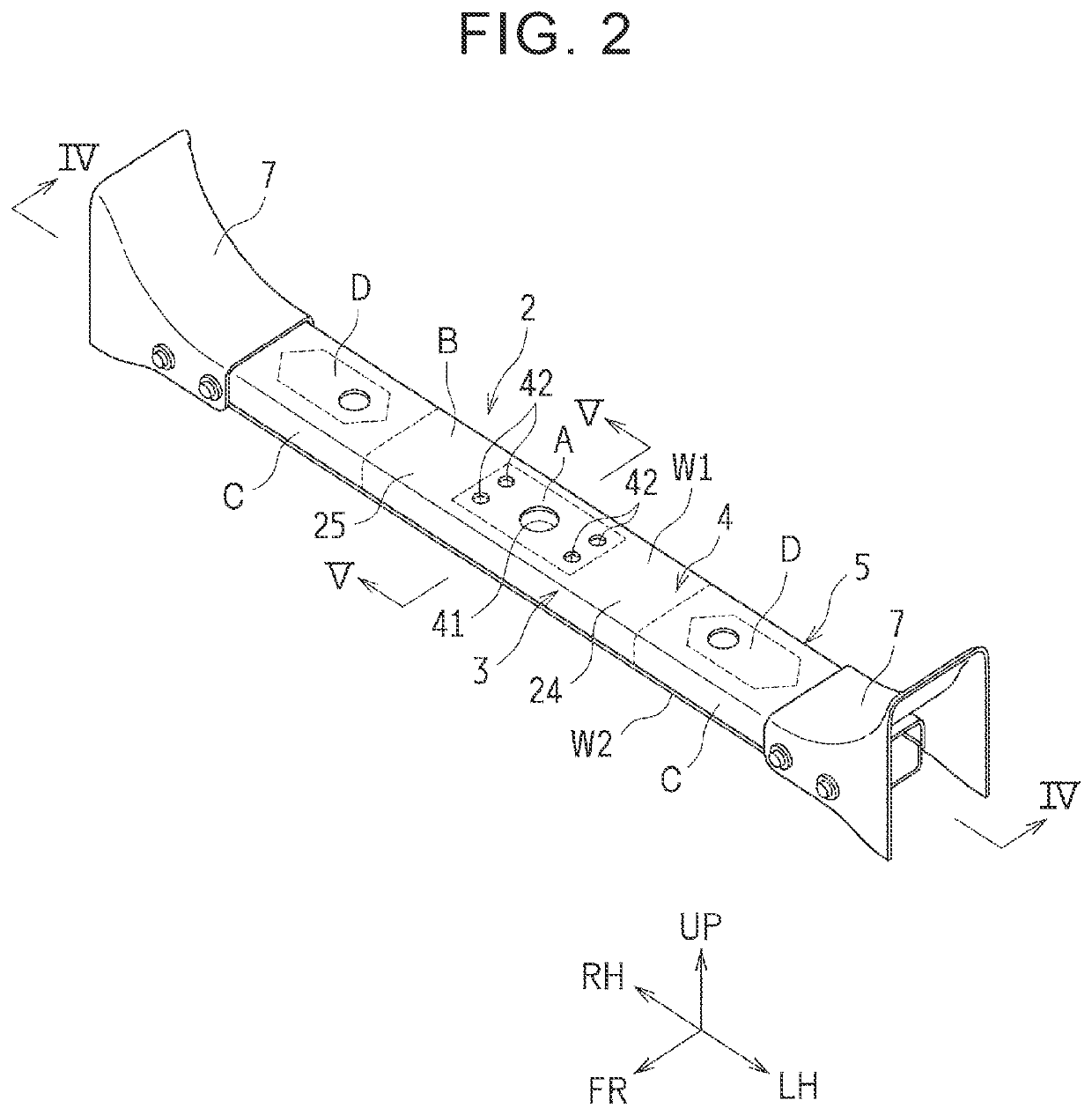

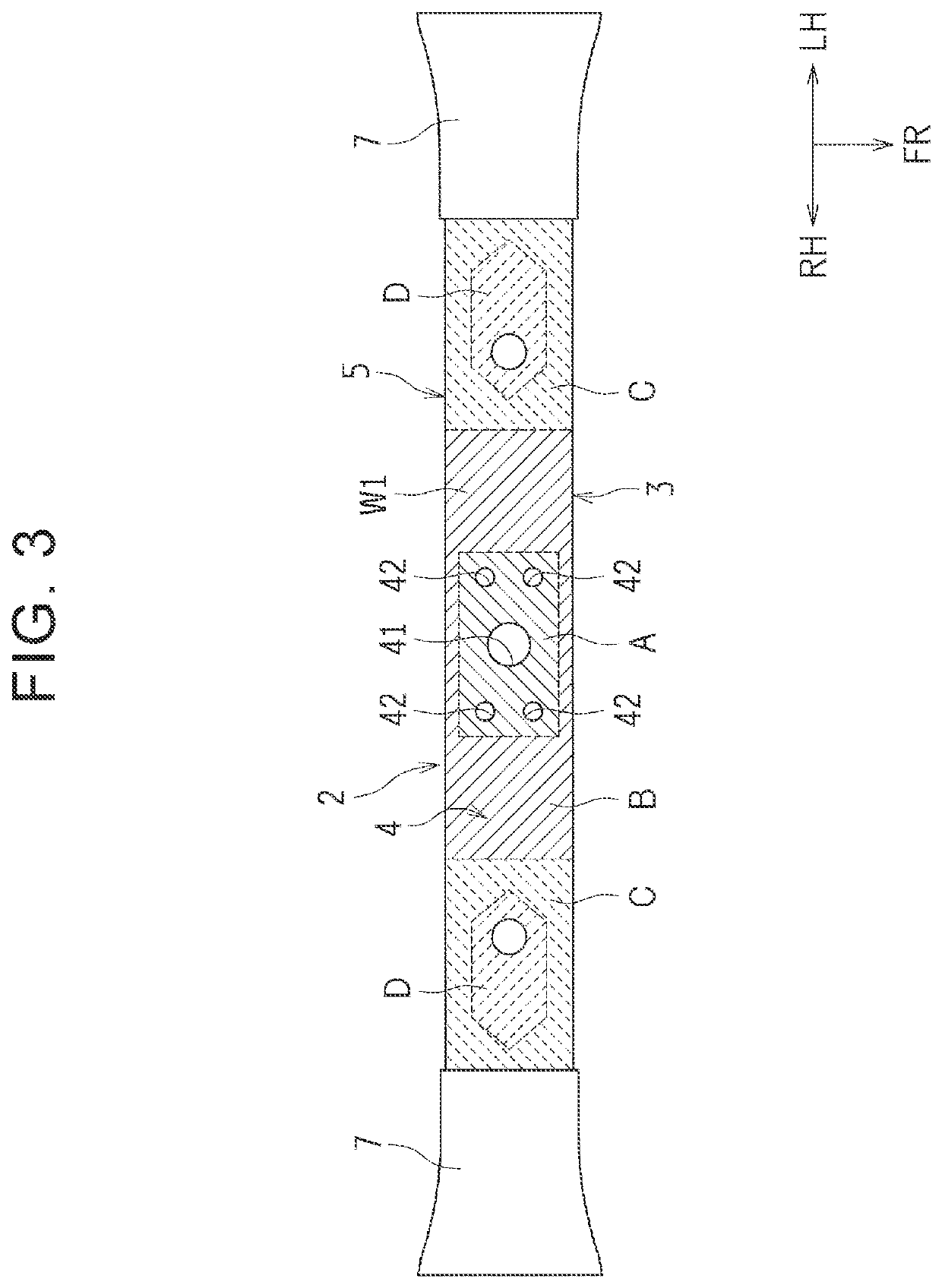

Crossmember and manufacturing method for crossmember

ActiveUS20200079429A1Reduced Thickness DimensionsIncrease manufacturing costUnderstructuresSuperstructure subunitsMetal sheetEngine mount

A crossmember and a manufacturing method for a crossmember is disclosed. The crossmember is made of a metal sheet having a given sectional shape, configures a part of a vehicle body frame, extends along a vehicle width direction, and has an engine mount attaching portion provided in a part of an upper plate portion. The crossmember has an upper crossmember that is made of a single metal sheet extending along the vehicle width direction, the upper crossmember having a larger thickness in a region including the engine mount attaching portion of the upper plate portion and a surrounding area of the engine mount attaching portion compared to a thickness of a remaining region.

Owner:TOYOTA JIDOSHA KK

Circular radiator box molding method

The invention discloses a circular radiator box molding method and relates to the technical field of special automotive manufacturing. A molding die utilized in the circular radiator box molding method comprises an upper die and a lower die. The upper die comprises a cylindrical male die and a connecting plate fixed to the male die. The lower die comprises a female die with a circular cavity; the bottom of the female die is fixedly connected to a base plate, and padding bars are arranged under the base plate. The box molding steps include fixing the upper die to a bending punch of a bending machine through bolts, removing the bending punch of the bending machine, debugging and centering the lower die on a workbench and fixing the lower die to the workbench, placing a blank into the circular cavity of the female die, closing the upper die and the lower die of the molding die and then punching the blank, and finally opening the upper die and the lower die to obtain a circular box. Compared with the prior art, the circular box molding method has the advantages that manufacturing cost is lowered greatly since the original bending machine is utilized and an extra punch machine is omitted, and further, the circular box has good quality when punched and formed, and the molding speed, the level of automation and the production efficiency are high.

Owner:SINOTRUK LIUZHOU YUNLI SPECIAL PURPOSE VEHICLES

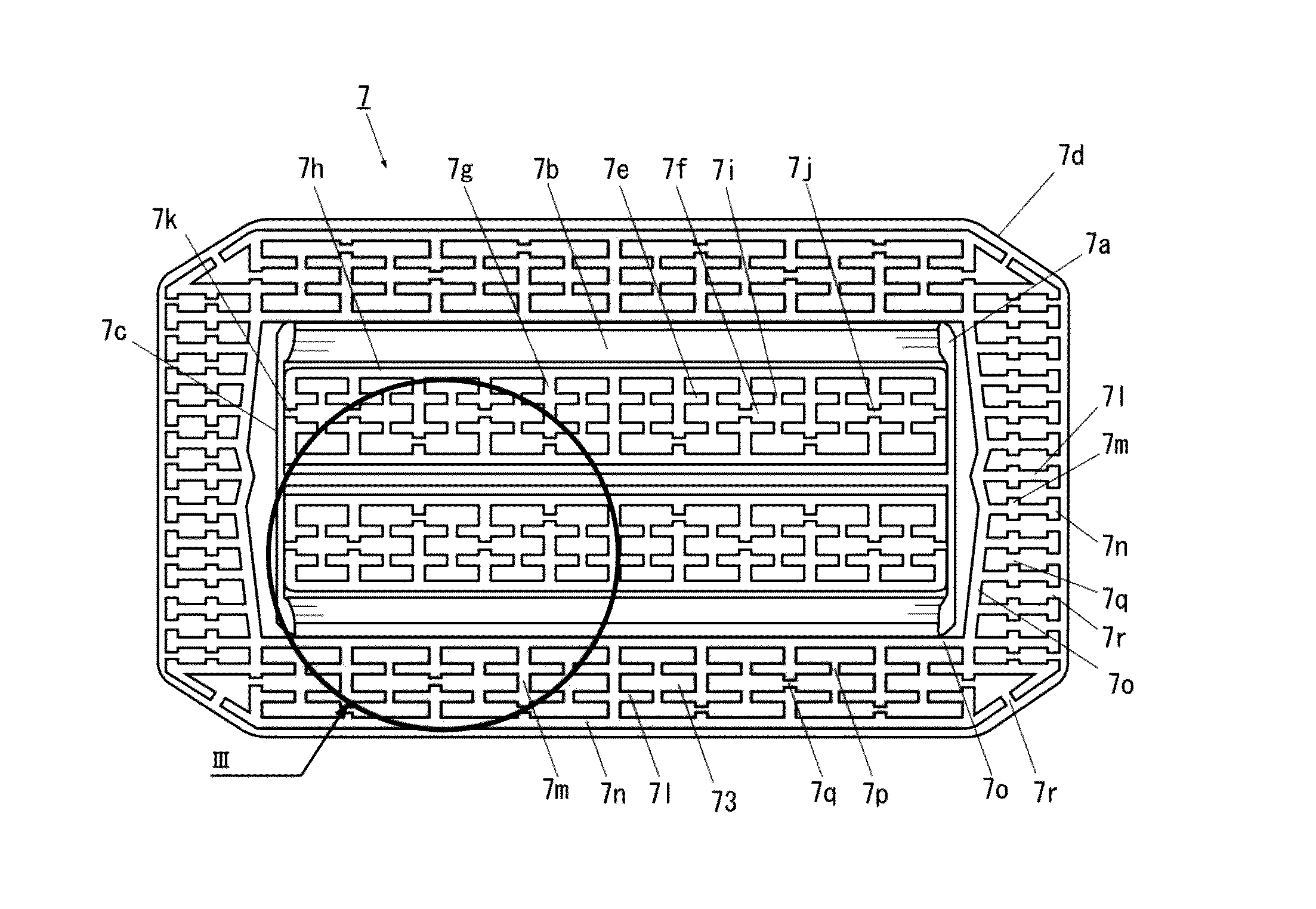

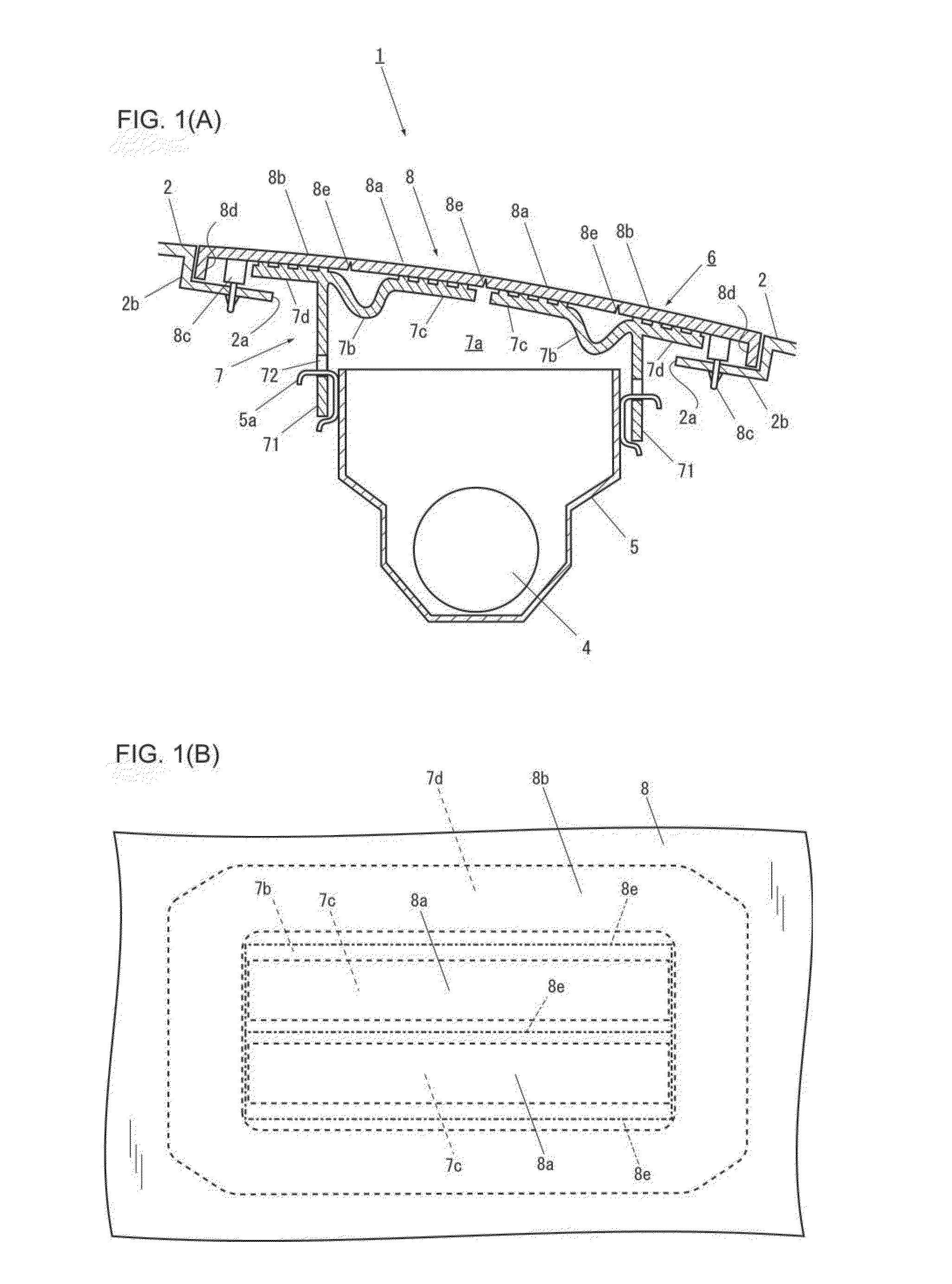

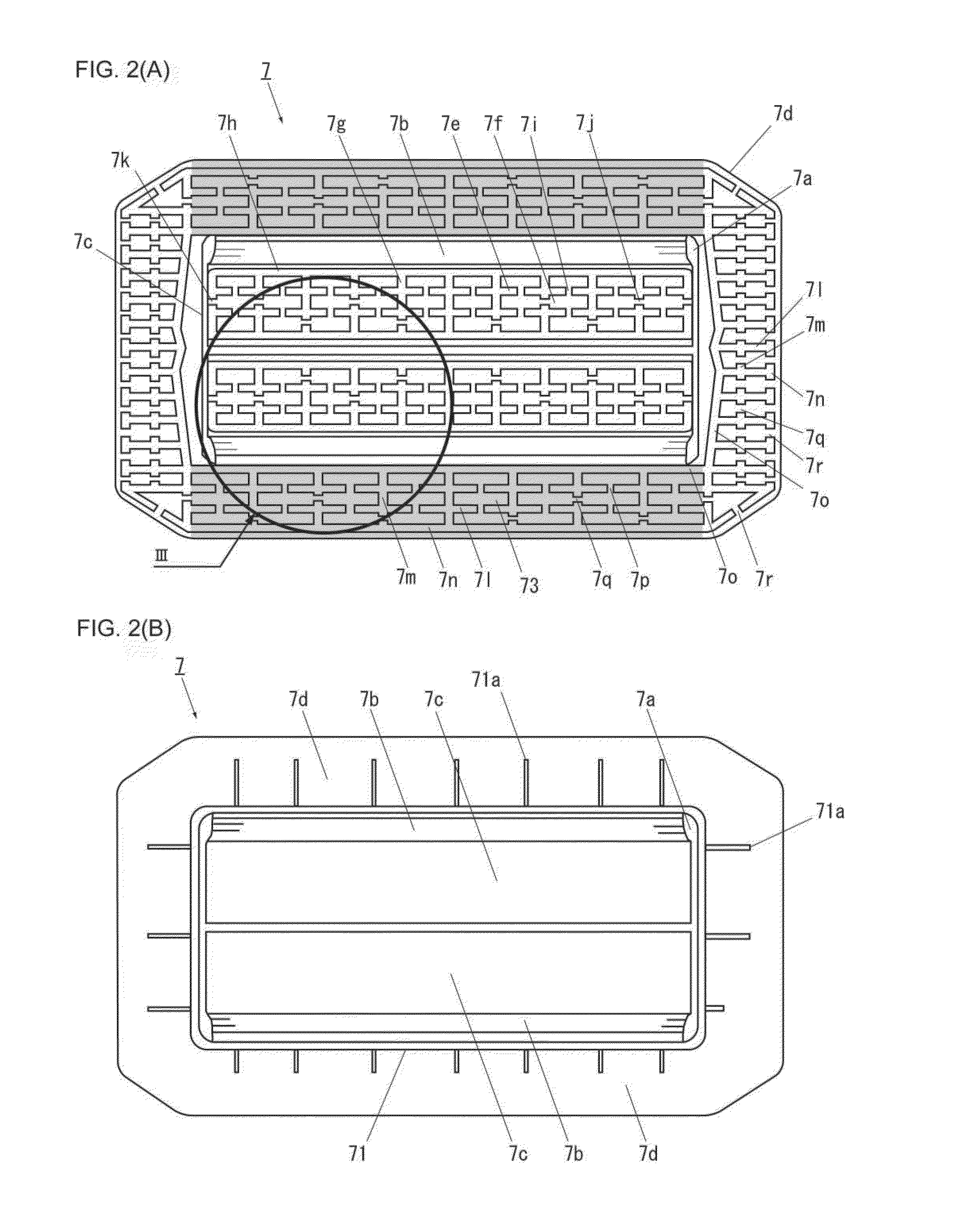

Vehicle interior panel, and airbag device

InactiveUS8657327B2Reduce welding strengthReduce rigidityPedestrian/occupant safety arrangementSuperstructure subunitsEngineeringAirbag

Provided are a vehicle interior panel and an airbag device wherein it is possible to prevent the weld strength and the rigidity of a panel from deteriorating. In a vehicle interior panel, a joint surface of a flap portion has first welding ribs, second welding ribs, and a third welding rib formed thereon. The first welding ribs include the first communication grooves each allowing adjacent grids and to communicate with each other. The second welding ribs include second communication grooves each allowing adjacent grids to communicate with each other. The third welding rib includes third communication grooves formed on sides substantially perpendicular to a hinge portion. The second communication grooves are formed so as not to be successively aligned in a direction perpendicular to the second welding ribs. The first to third communication grooves form an exhaust channel allowing the air in the grids to be discharged outside during vibration welding.

Owner:JOYSON SAFETY SYST JAPAN KK

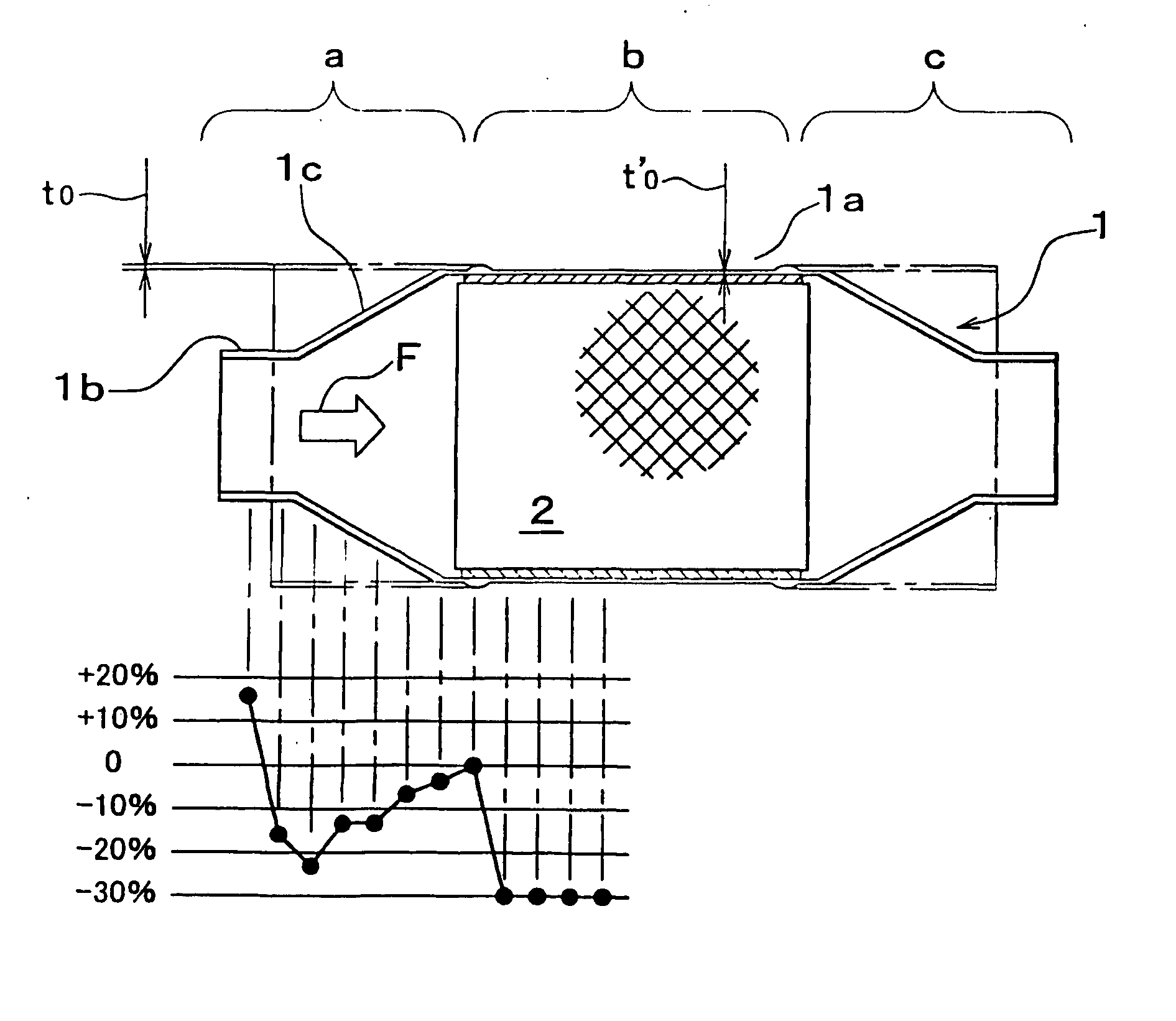

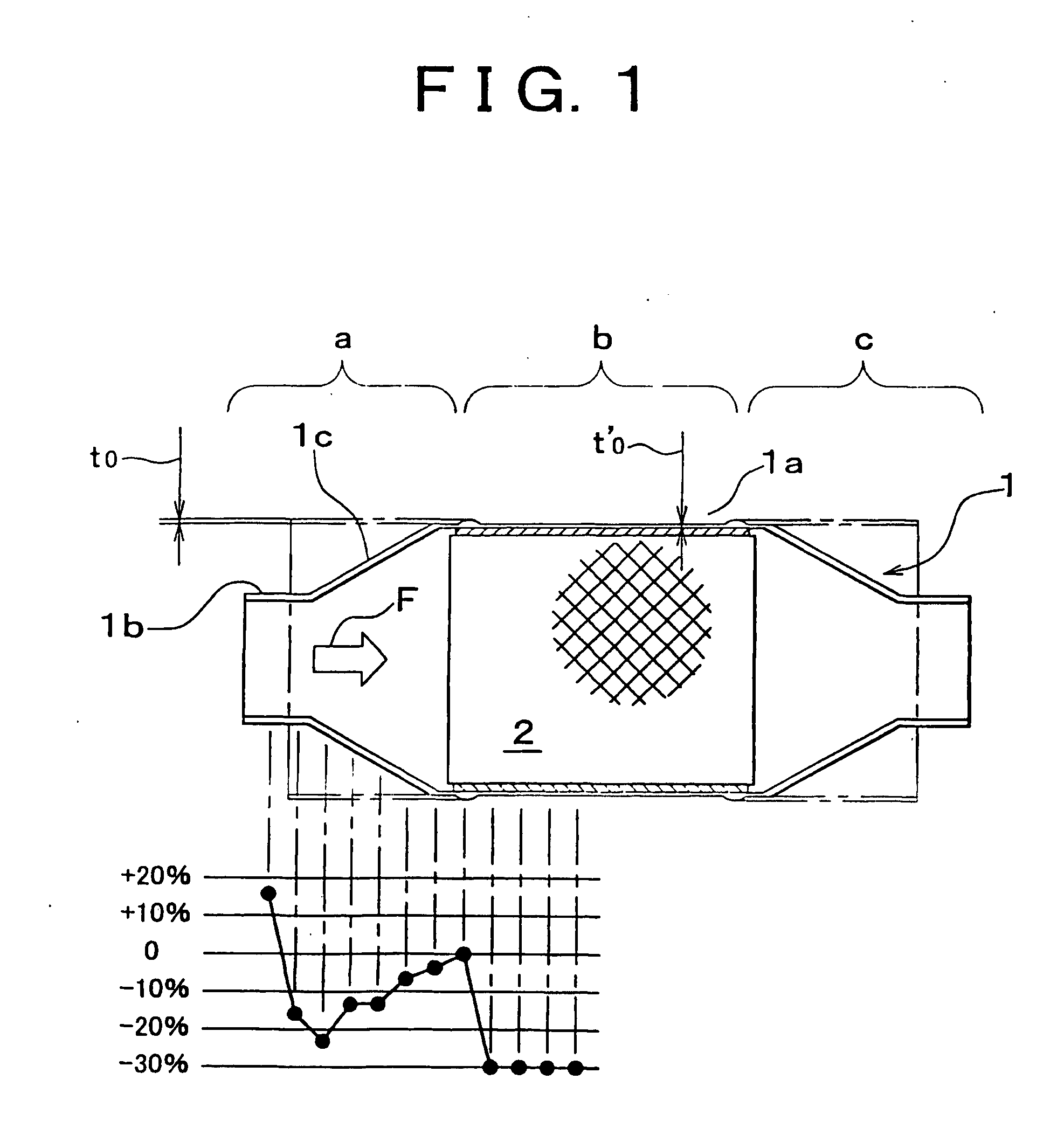

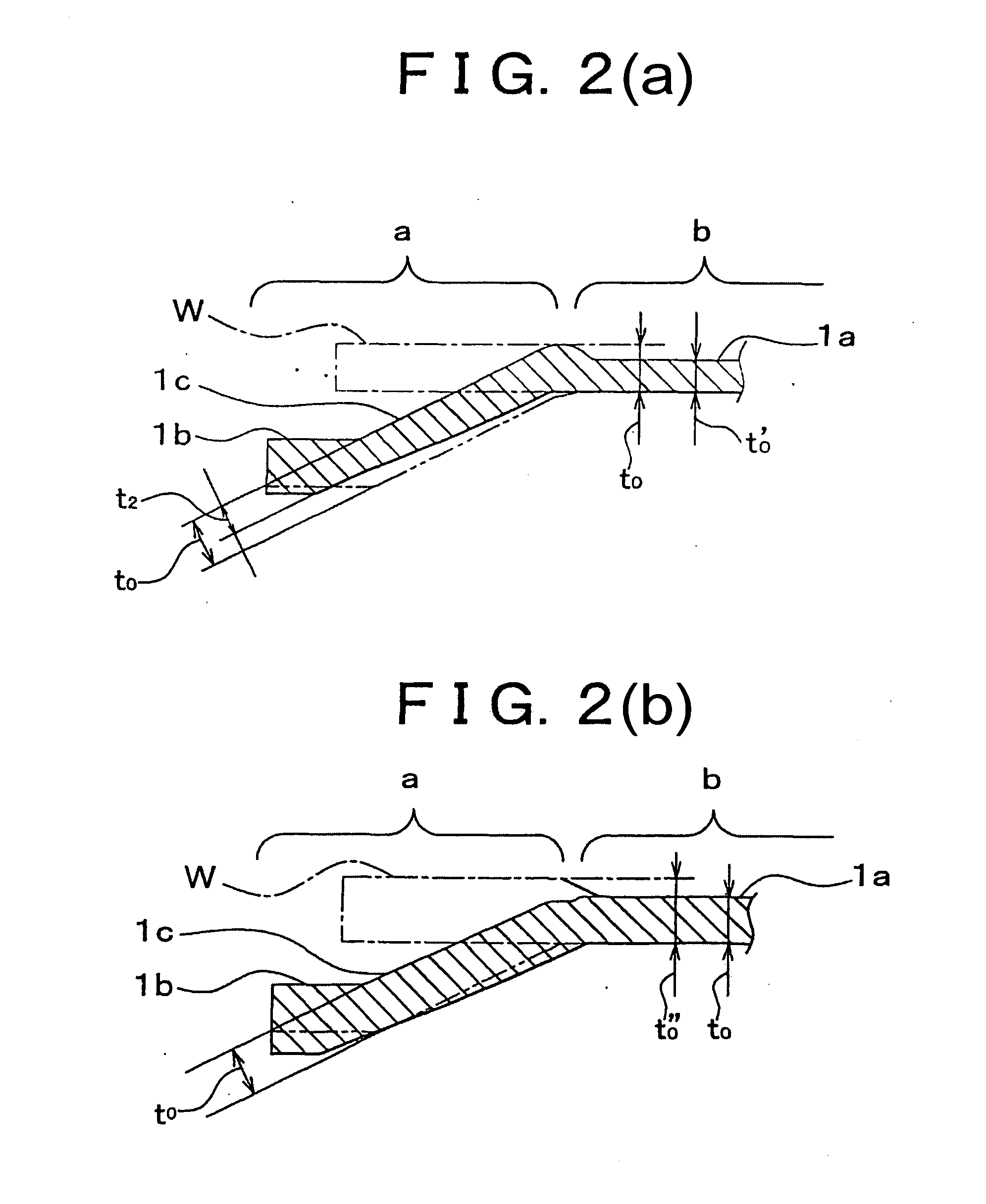

Hollow member, manufacturing method thereof, fluid distribution system using the hollow member, and forming apparatus of hollow material

InactiveUS20080028609A1Easy to controlImprove air tightnessExhaust apparatusCurved planar seam weldingDistribution systemEngineering

A manufacturing method of a catalyst container includes forming a plate member that is partially different in plate thickness or material by joining material plates that are different in plate thickness or material by welding; bending the plate member that is partially different in plate thickness or material to form a hollow material, wherein the hollow material is formed by bending the plate member and joining opposing sides thereof by welding; and changing a sectional shape of the hollow material by a spinning process.

Owner:TOYOTA JIDOSHA KK

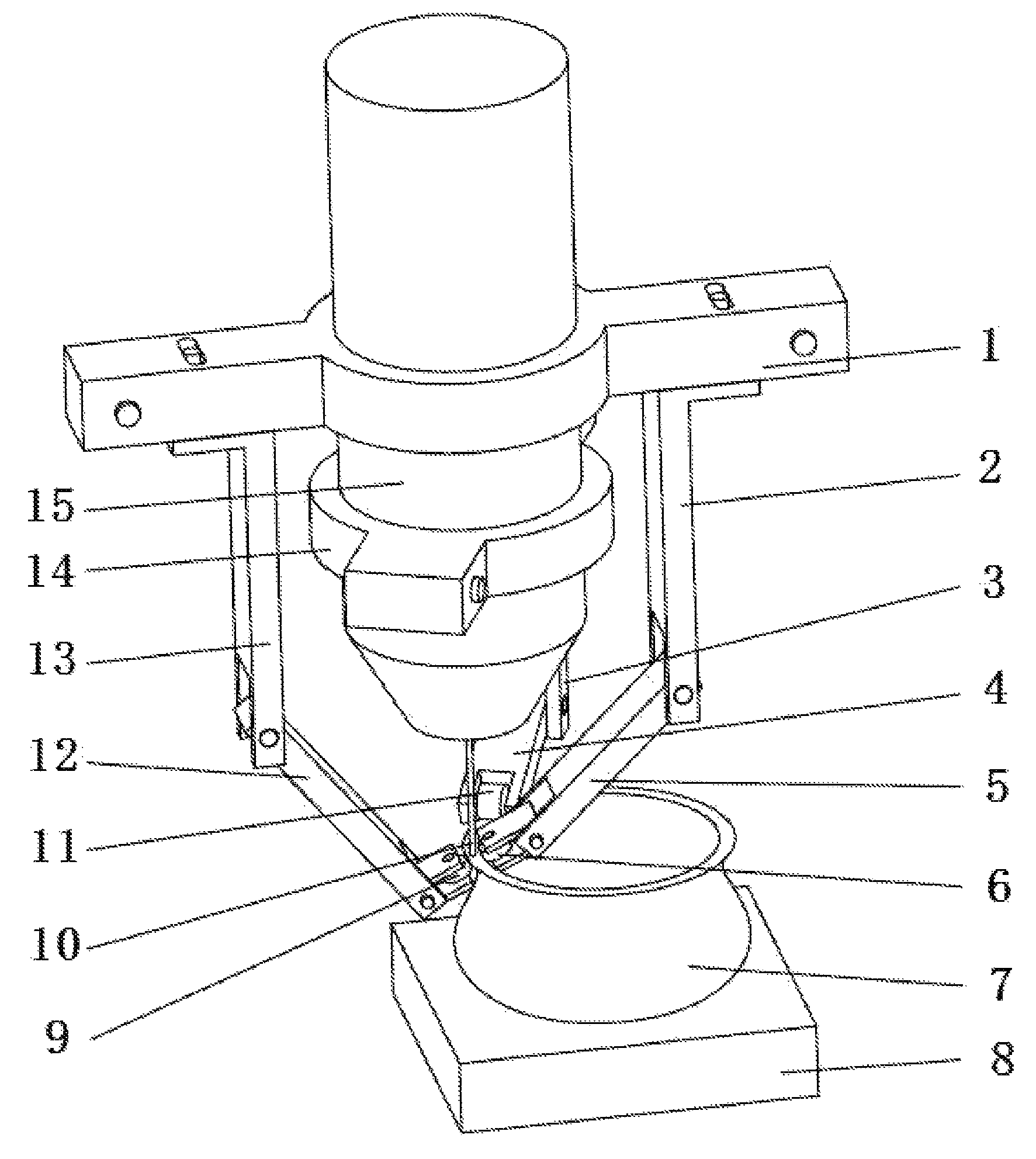

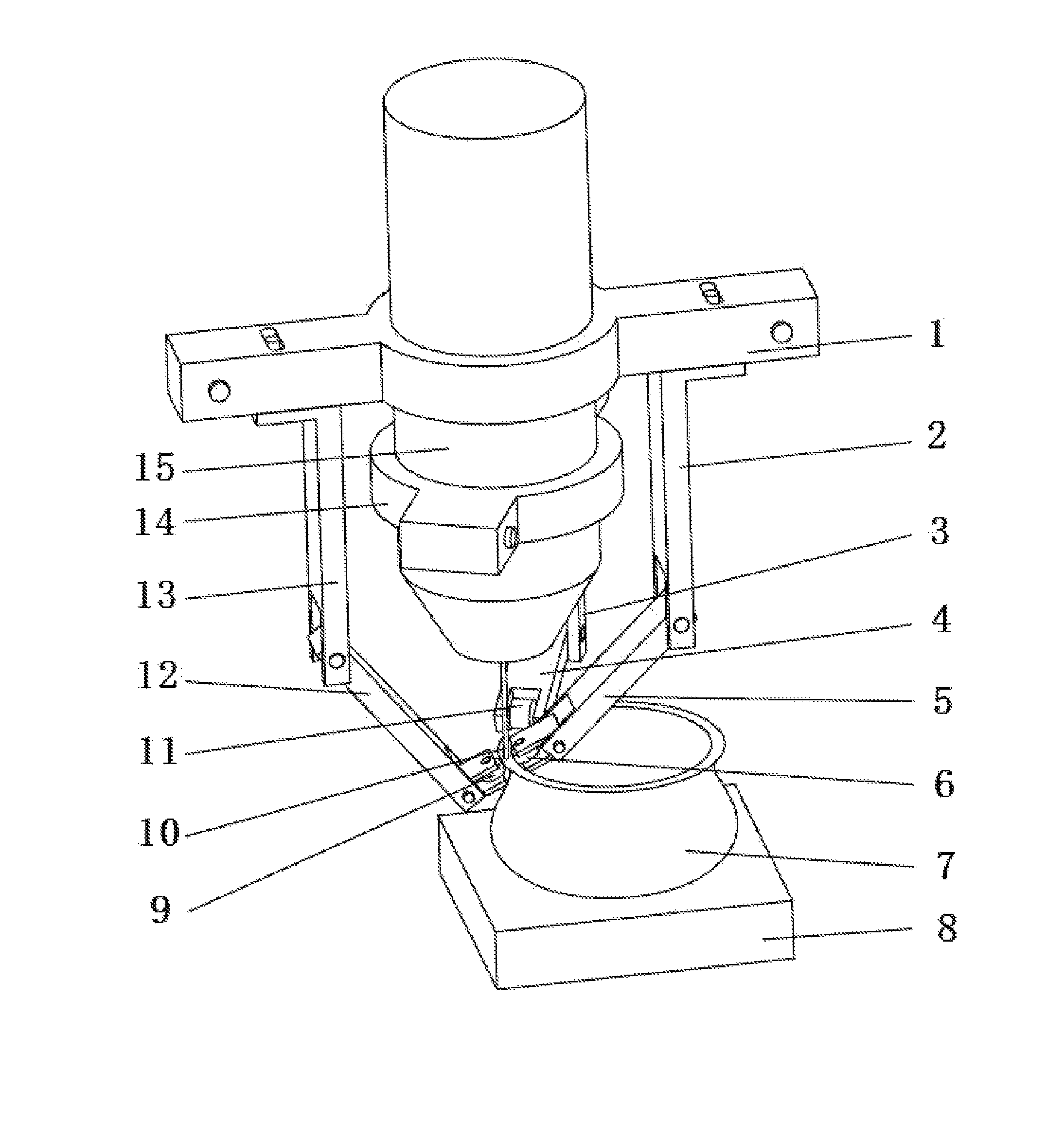

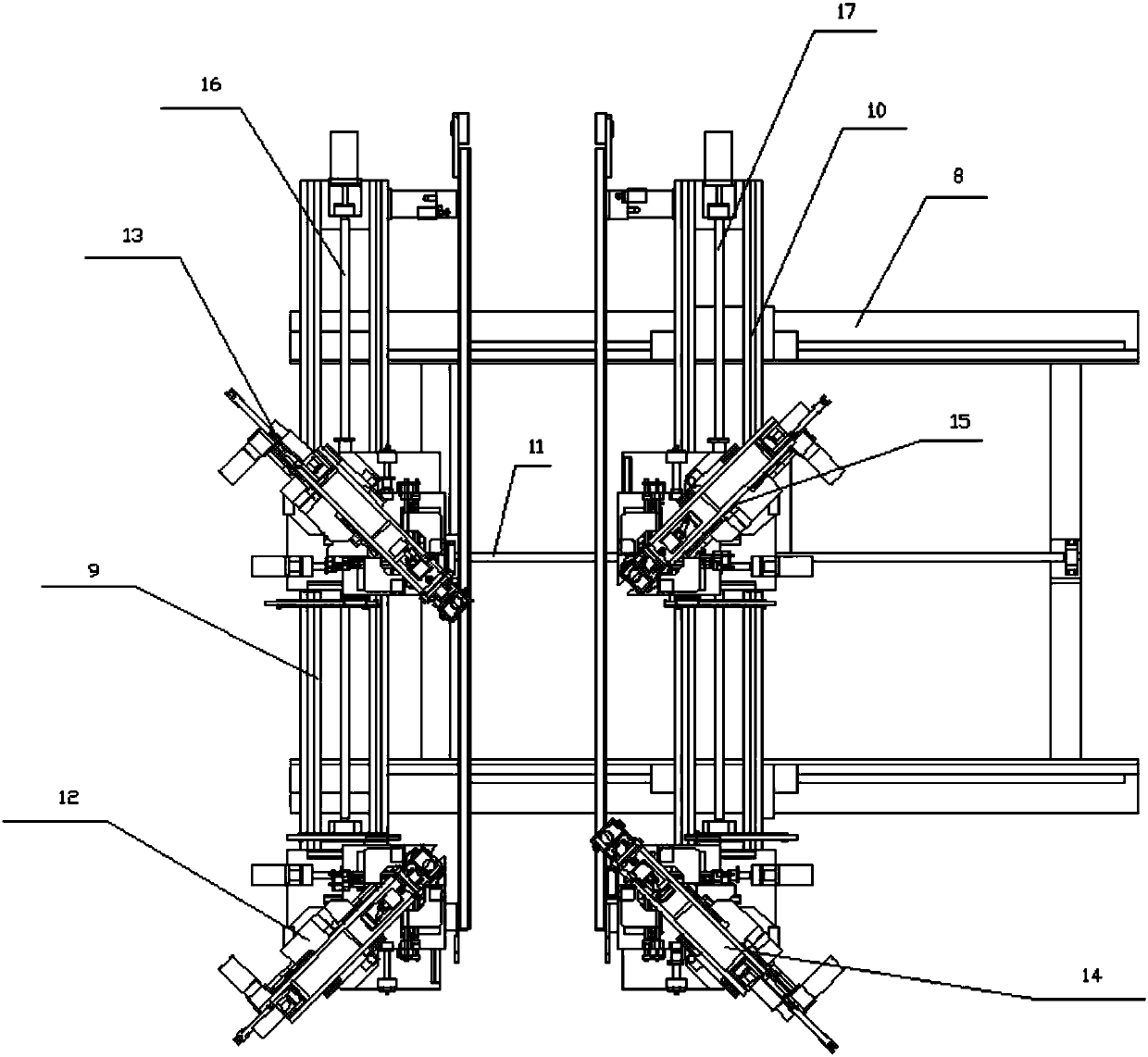

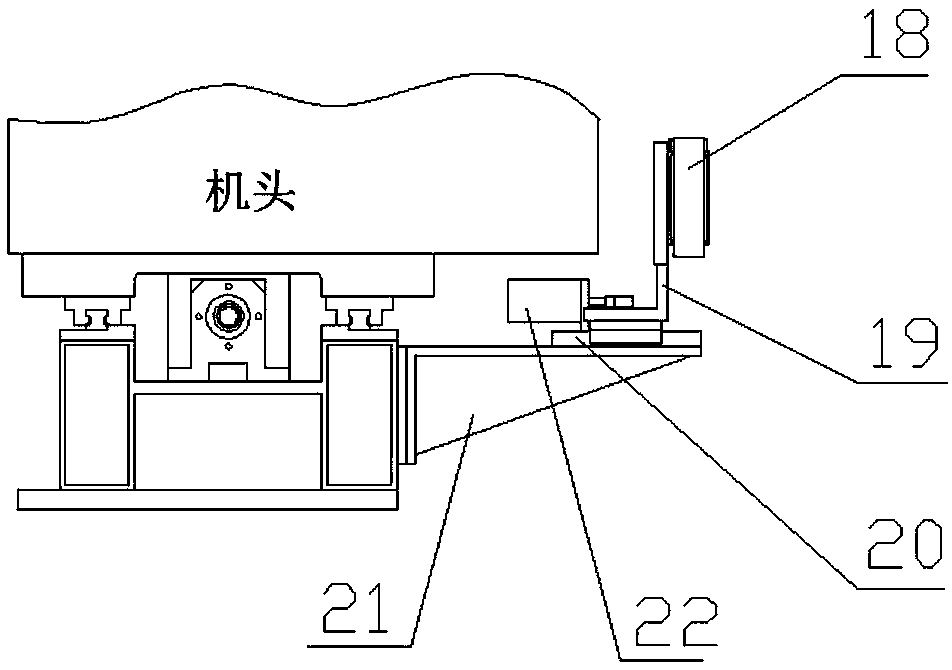

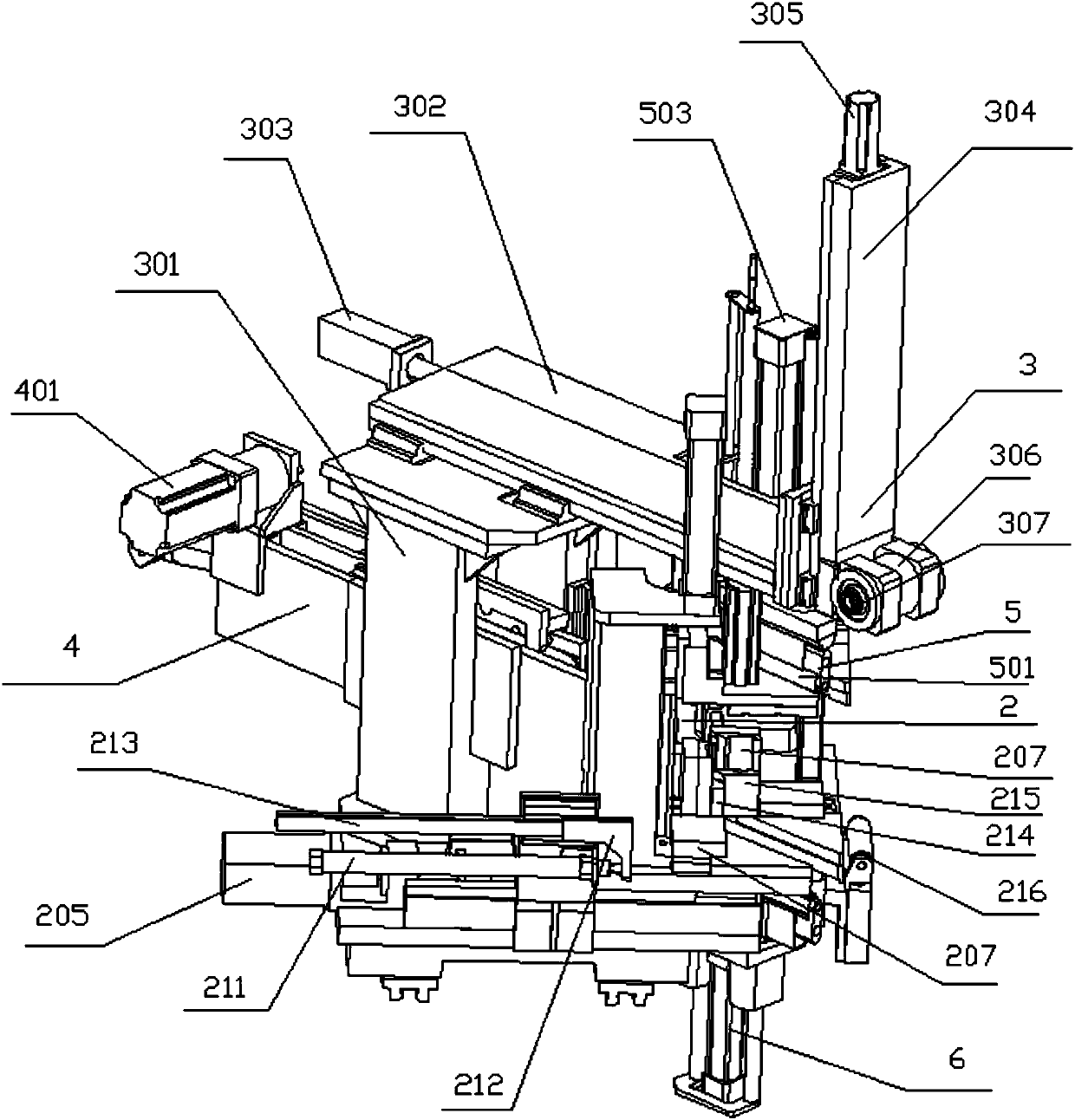

Four-corner welder and welding method for welding plastic doors and windows

PendingCN107639843ALower requirementReduce weld flash cleaning processFramesEngineeringIndustrial engineering

The invention relates to a four-corner welder and a welding method for welding plastic doors and windows. The four-corner welder comprises a machine base, wherein a left rack and a right rack are arranged on the machine base; the left rack is fixed at the left end of the machine base; the right rack is driven by a driving device to do back-forth and left-right sliding along the machine base; a left-lower machine head is arranged at one end of the left rack; a left-upper machine head is arranged at the other end of the left rack; a right-lower machine head is arranged at one end of the right rack; a right-upper machine head is arranged at the other end of the right rack; in addition, the left-upper machine head and the right-upper machine head are driven by the driving device to do back-forth sliding along the directions of the left-lower machine head and the right-lower machine head; conveying mechanisms for conveying profiles are arranged on the inner side of the left rack and the inner side of the right rack; a control cabinet is also arranged on one side of the machine base; an operation panel is arranged on the control cabinet, so as to realize the operation of the whole welder.

Owner:山东辰禾智能装备有限公司

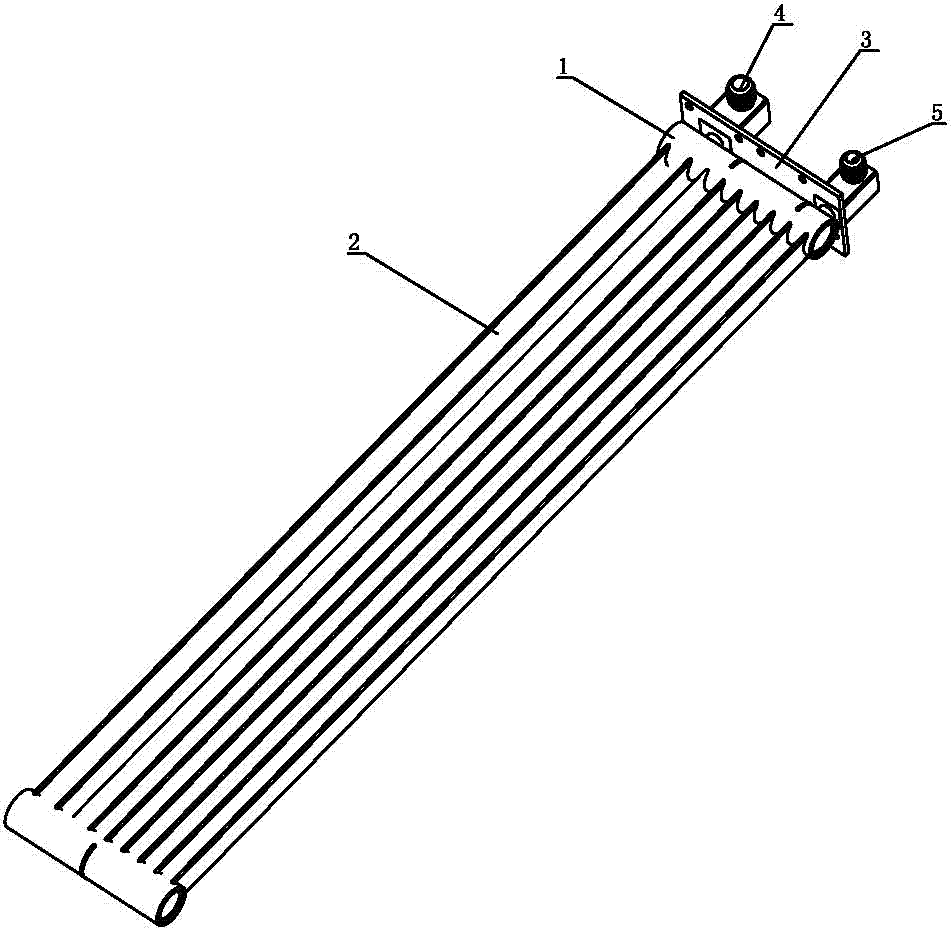

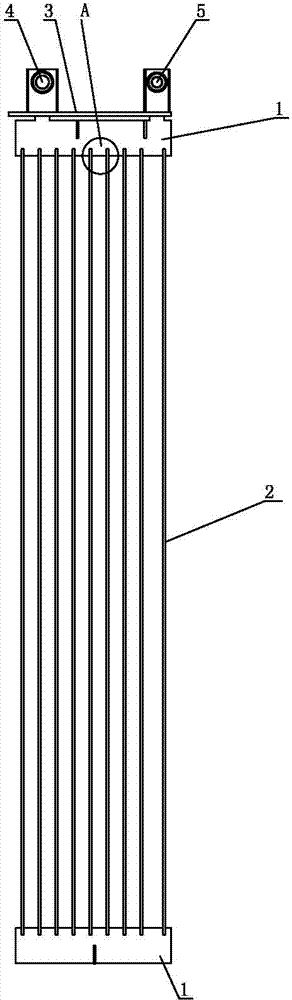

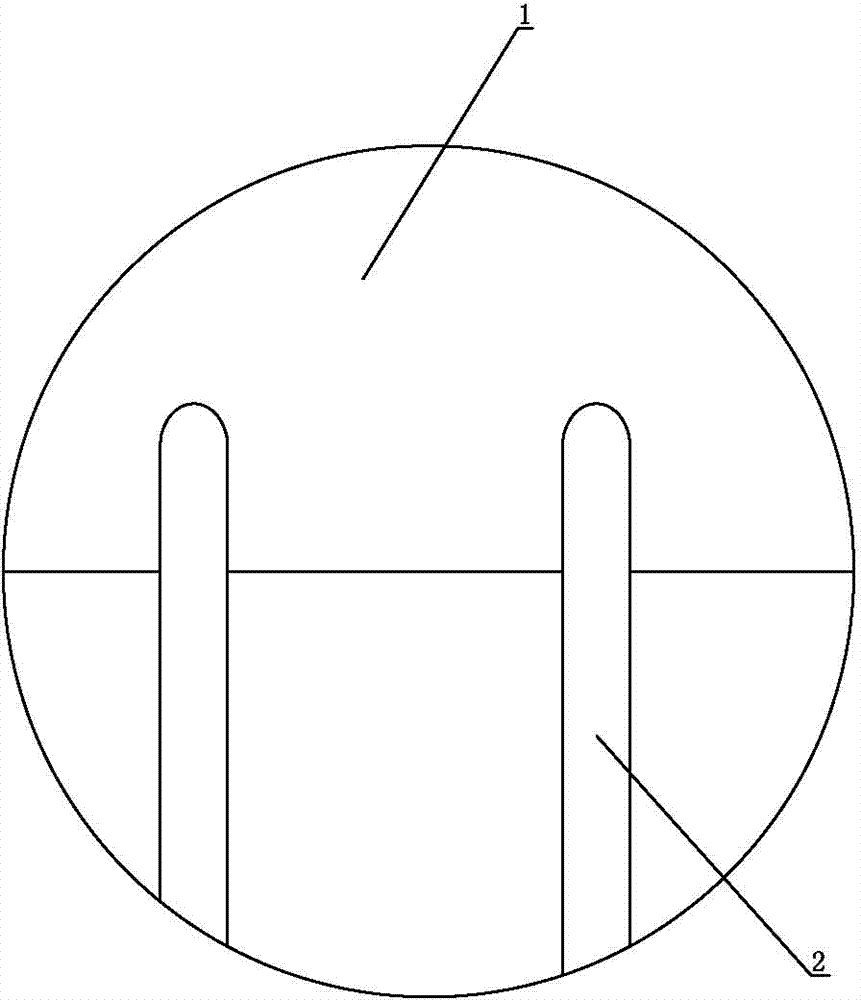

Machining technology of non-fin heat exchanger

InactiveCN103658902AAvoid deformationAvoid stretchingSoldering apparatusWelding/soldering/cutting articlesEngineeringSolder paste

The invention discloses a machining technology of a non-fin heat exchanger. The non-fin heat exchanger comprises tube bodies and flat tubes. The machining technology of the non-fin heat exchanger comprises the following steps that (1) inserting holes are formed in the periphery of each tube body; (2) the two ends of each flat tube are inserted into the corresponding inserting holes formed in the tube bodies located at the two ends respectively; (3) a welding locating tool is arranged between every two flat tubes; each welding locating tool comprises a hollow tube, a clamping groove is formed in the tube wall of each hollow tube, and the flat tubes are clamped into the clamping grooves; (4) the portions, located on the connecting portions of the tube bodies and the flat tubes, of the tube bodies and the flat tubes are coated with soldering paste; (5) the two sides of each flat tube are respectively provided with a reinforcing welding rod attached to the circumferential walls of the corresponding tube bodies; (6) the portions, located at the connection portions of the tube bodies and the flat tubes, of the tube bodies and the flat tubes are coated with brazing flux and the mass concentration of the brazing flux is 30%-40%; (7) the tube bodies and the flat tubes are placed in a brazier together with the welding locating tools for brazing. By the adoption of the machining technology, good-quality welding of the non-fin heat exchanger is achieved.

Owner:GUANGZHOU JINGYI AUTOMOBILE AIR CONDITIONER

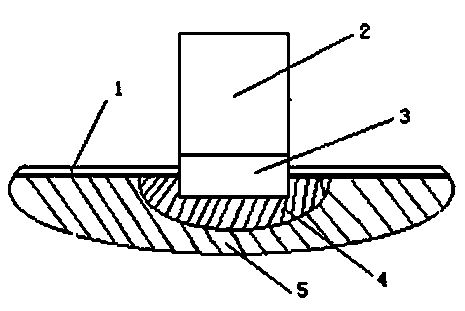

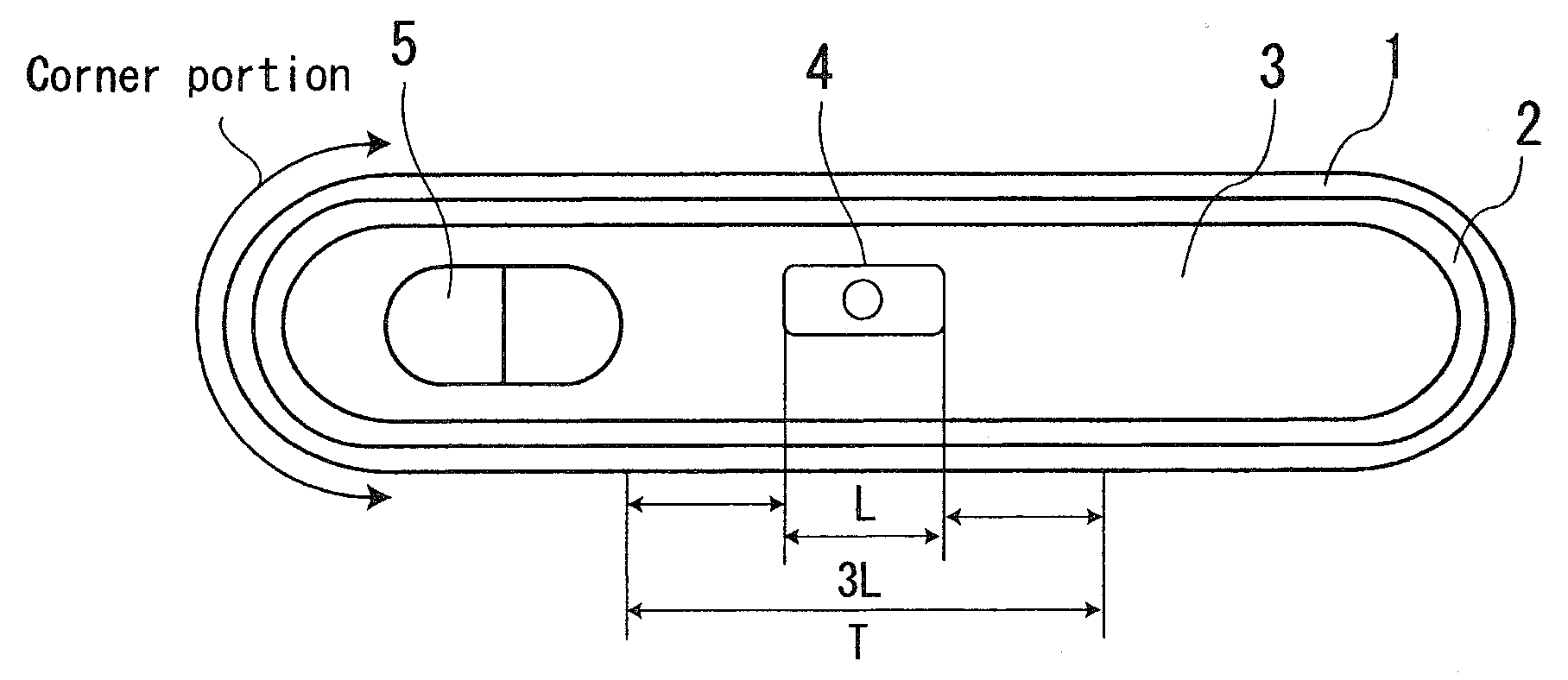

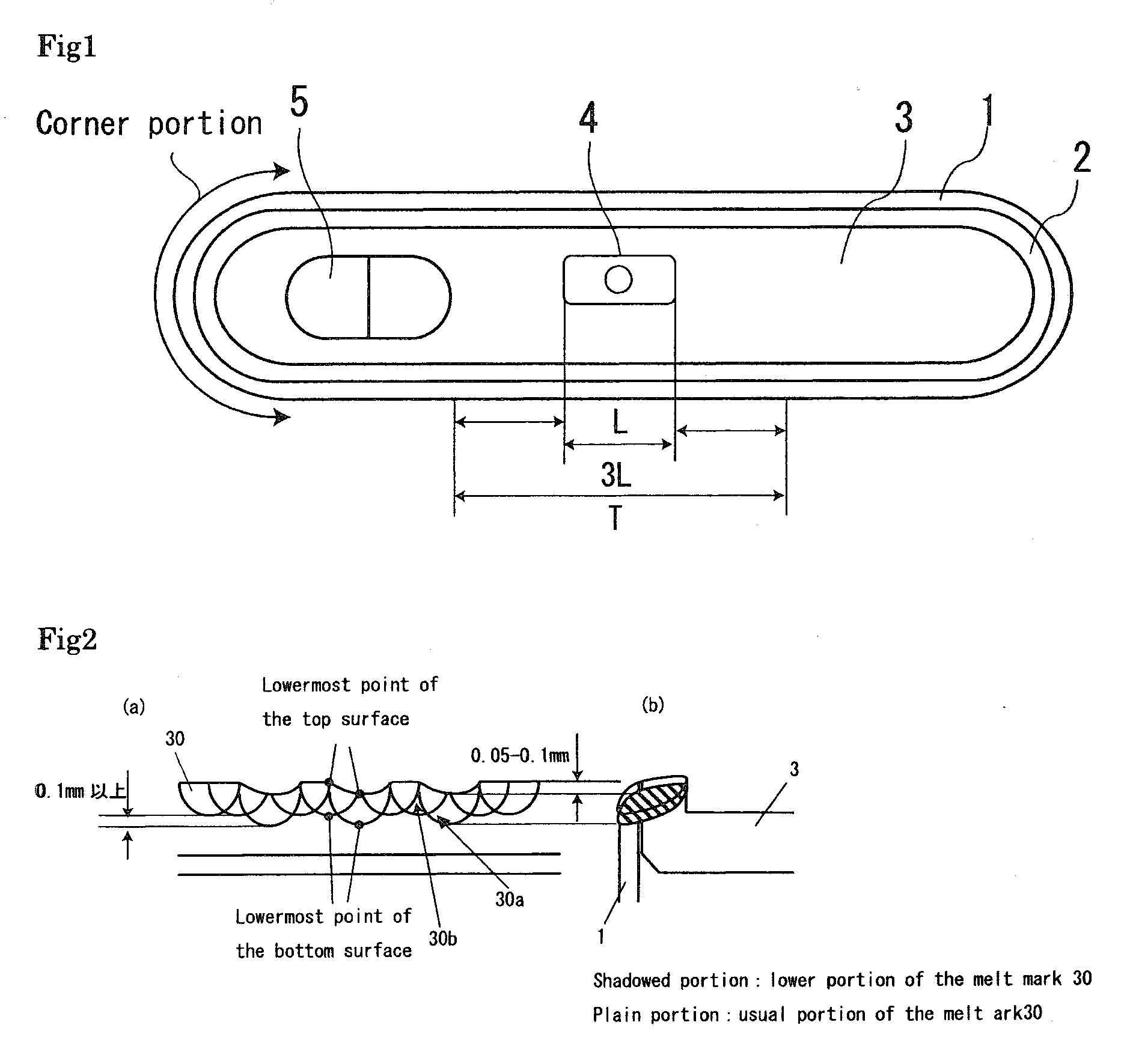

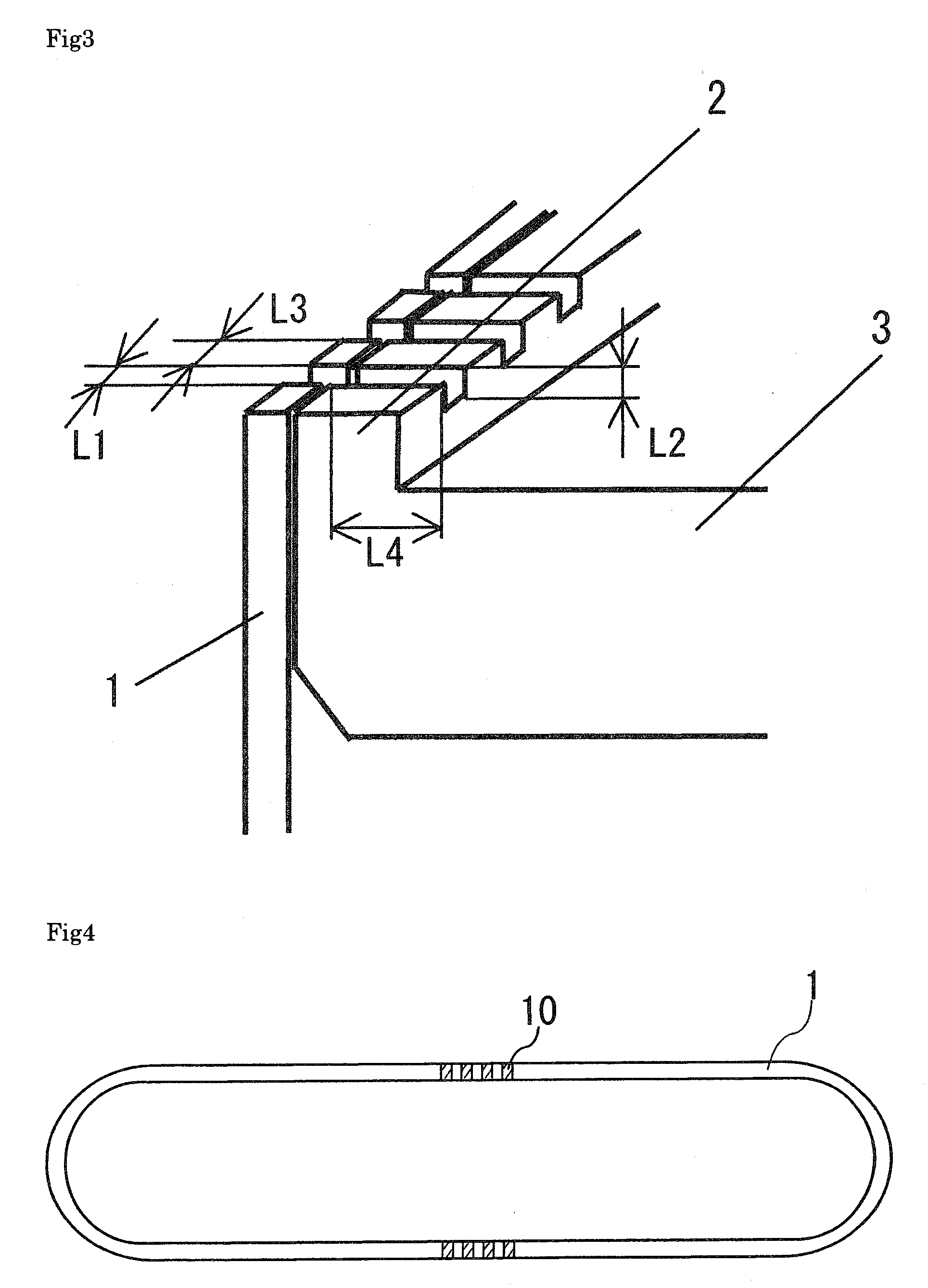

Hermetic cell and method for producing same

InactiveUS20080160234A1Improve welding strengthAvoid deformationEnvelopes/bags making machineryFinal product manufactureEngineeringWeld strength

A hermetic cell excellent in weld strength is provided. The hermetic cell includes an can having an opening and a seal for sealing the opening of the can. A portion of engagement of the seal with the opening of the can is welded with a high energy beam, thereby hermetically sealing the can. At least one portion of a melt mark resulting from the high energy beam welding has a top surface having a lowermost point lower in a direction of a bottom of the can than a lowermost point of a top surface of an adjacent portion of the melt mark. The at least one portion of the melt mark has a bottom surface having a lowermost point lower in the direction of the bottom of the can than an lowermost point of a bottom surface of the adjacent portion of the melt mark.

Owner:SANYO ELECTRIC CO LTD

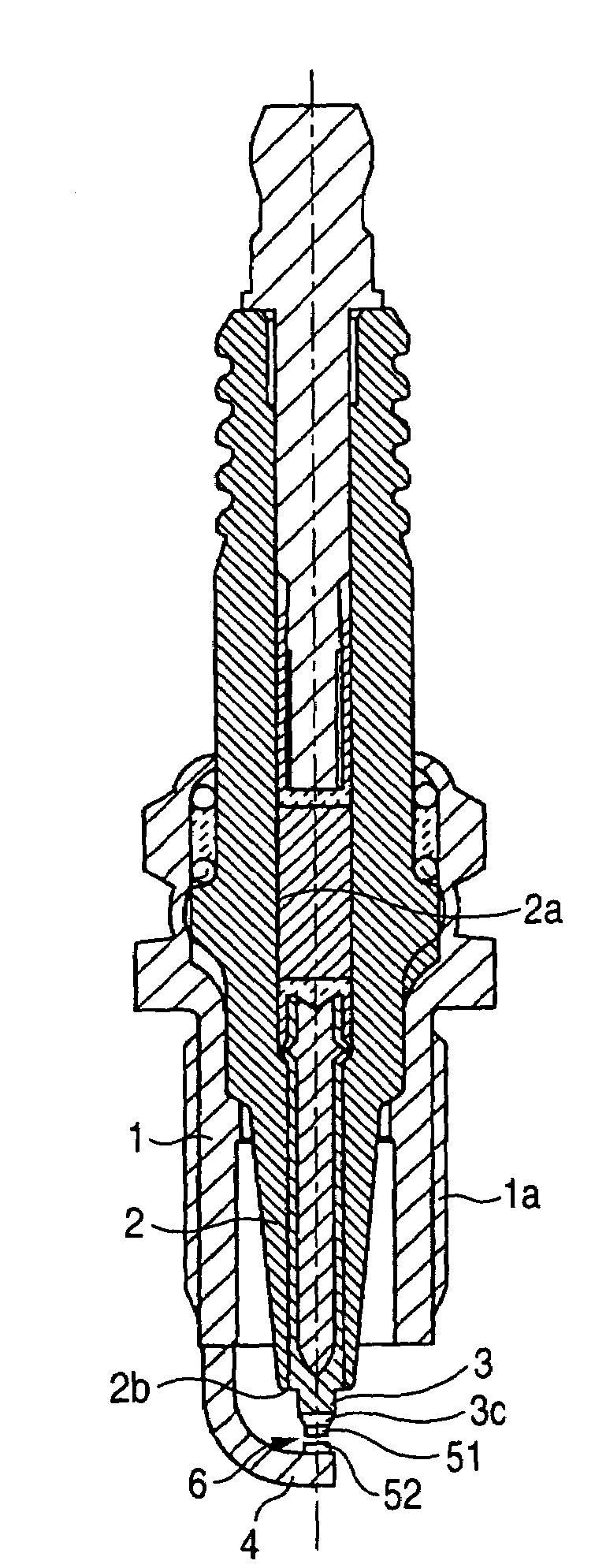

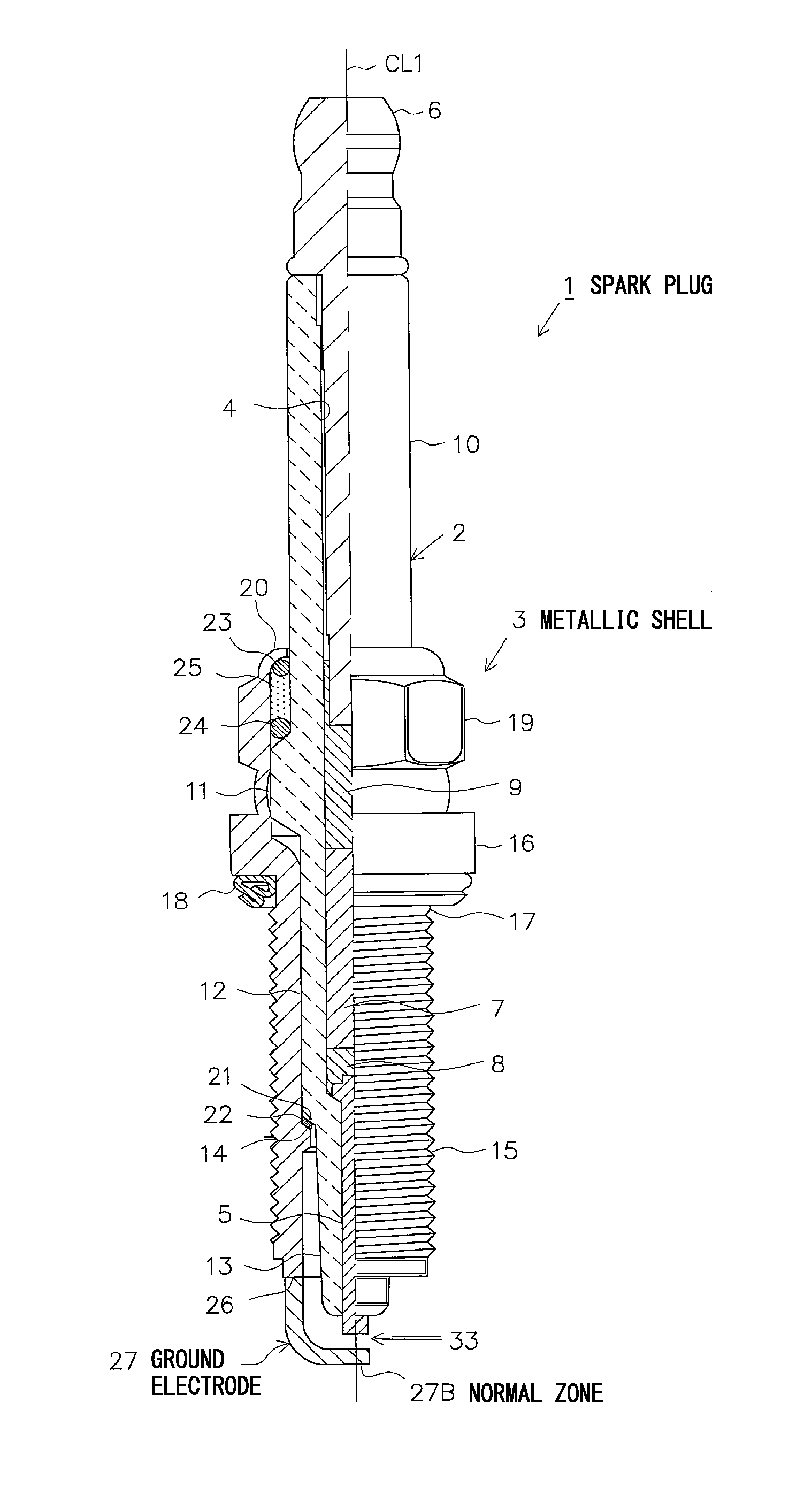

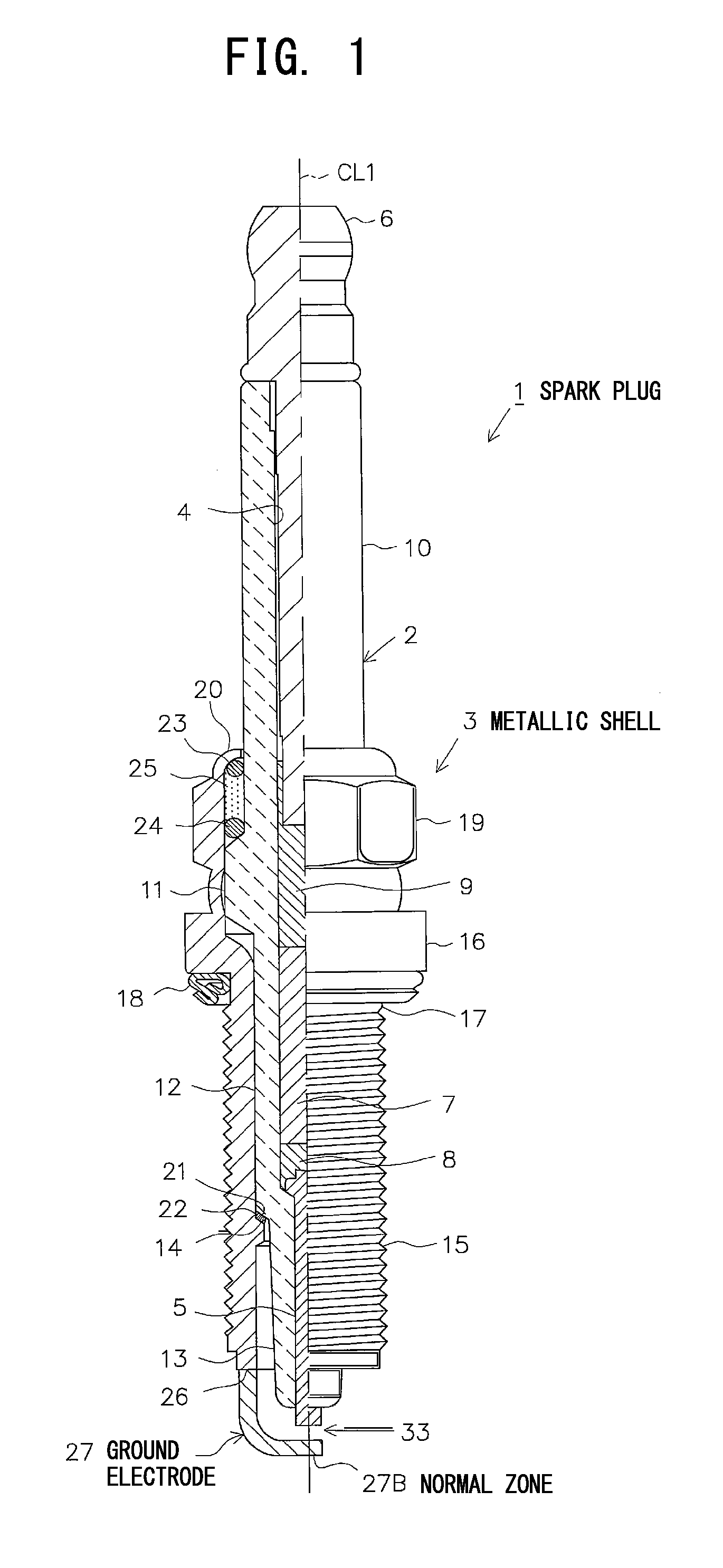

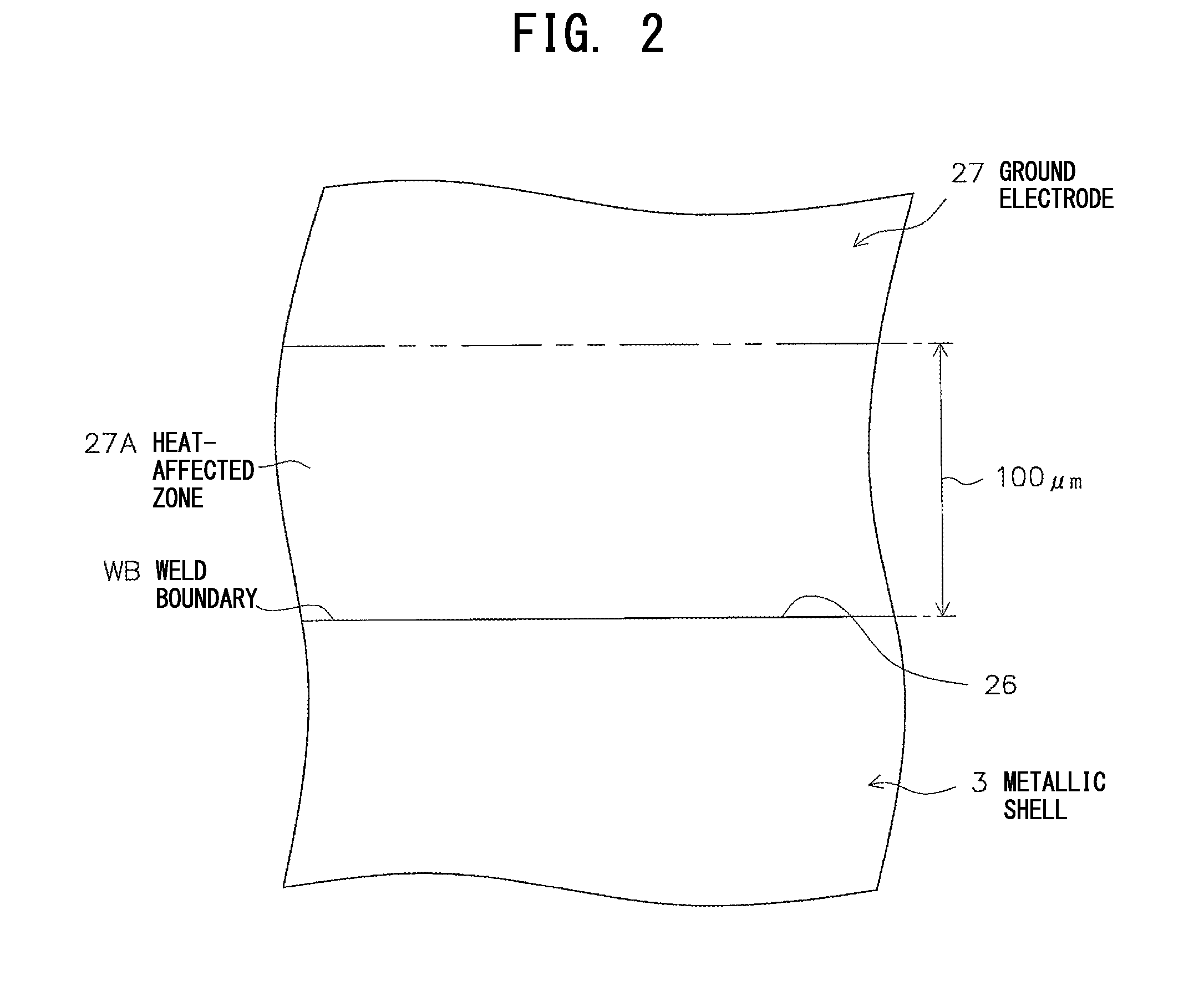

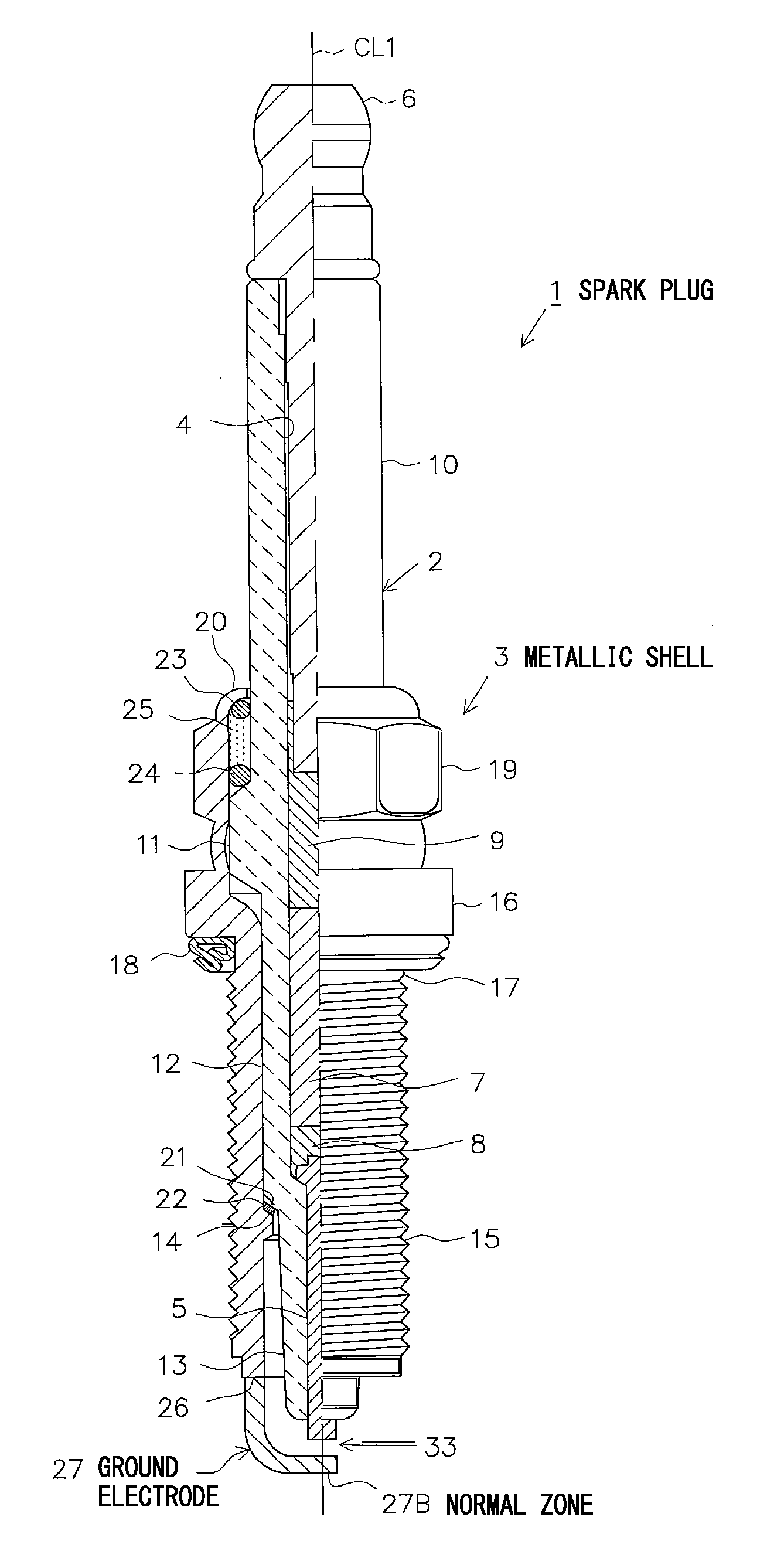

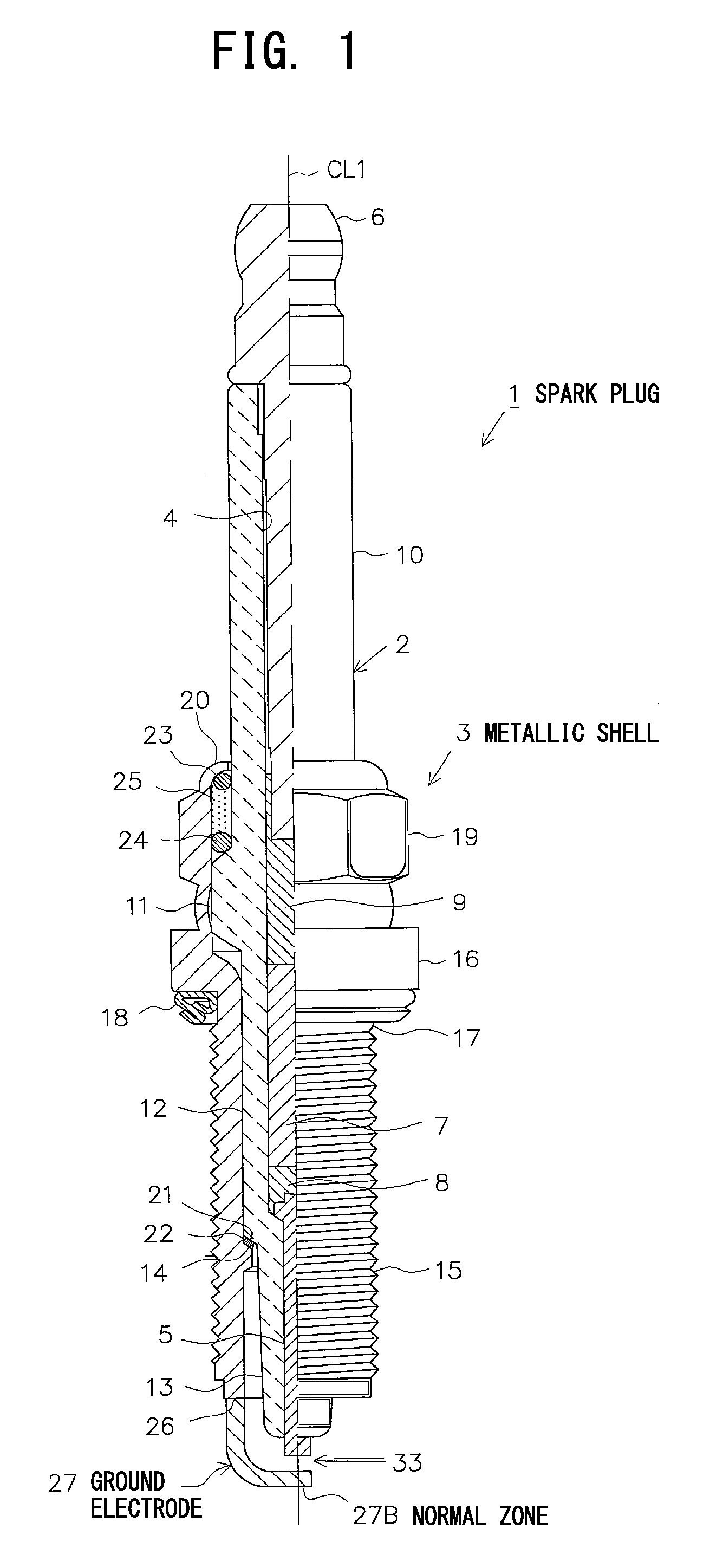

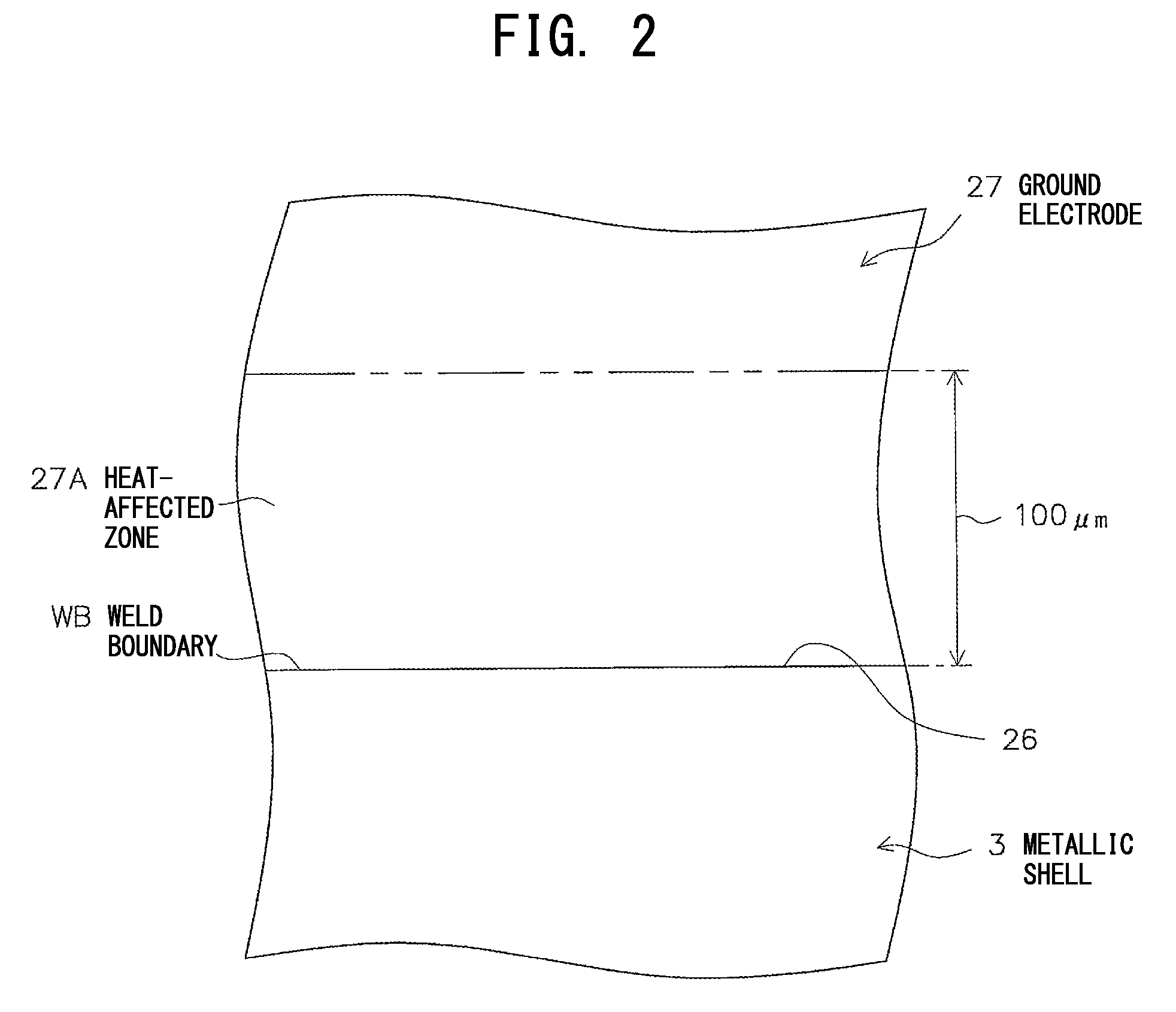

Spark plug

ActiveUS20130009538A1Improve corrosion resistanceIncreased durabilitySparking plugsWelding/cutting media/materialsNormal zoneHeat-affected zone

A spark plug (1) includes a metallic shell (3) and a ground electrode (27) resistance-welded to the metallic shell (3). The ground electrode (27) is formed from a metal material in which precipitates PR containing at least one of an oxide, an intermetallic compound, etc., are precipitated in grain boundaries. The diameter of an equivalent circle of a precipitate PR having the greatest area is 50 μm or less, and the shortest distance between the precipitates PR is 2 μm or greater. The area occupied by the precipitates PR on the section of the heat-affected zone 27A is equal to 65% or more the area occupied by the precipitates PR (the diameter of an equivalent circle of a precipitate PR having the greatest area) on a section of the normal zone 27B.

Owner:NGK SPARK PLUG CO LTD

Forming die for arc water tank of oil tank truck

The invention discloses a forming die for the arc water tank of an oil tank truck and relates to the technical field of special automobile manufacturing. The forming die comprises an upper die and a lower die. The upper die comprises a cylindrical male die and a connecting plate for being connected to the bending male die of a bending machine. The connecting plate is fixedly disposed on the male die and provided with a screw hole. The lower die is mounted on the working table of the bending machine. The lower die comprises a female die with an arc cavity. A base plate is fixedly connected to the bottom of the female die. Filler strips are disposed below the base plate. Compared with the prior art, the forming die has the advantages that the original bending machine is utilized, an additional punching machine is not needed, manufacturing cost is lowered greatly, the punched and formed arc water tank is good in quality, and the forming die is fast, high in automation level and high in production efficiency.

Owner:SINOTRUK LIUZHOU YUNLI SPECIAL PURPOSE VEHICLES

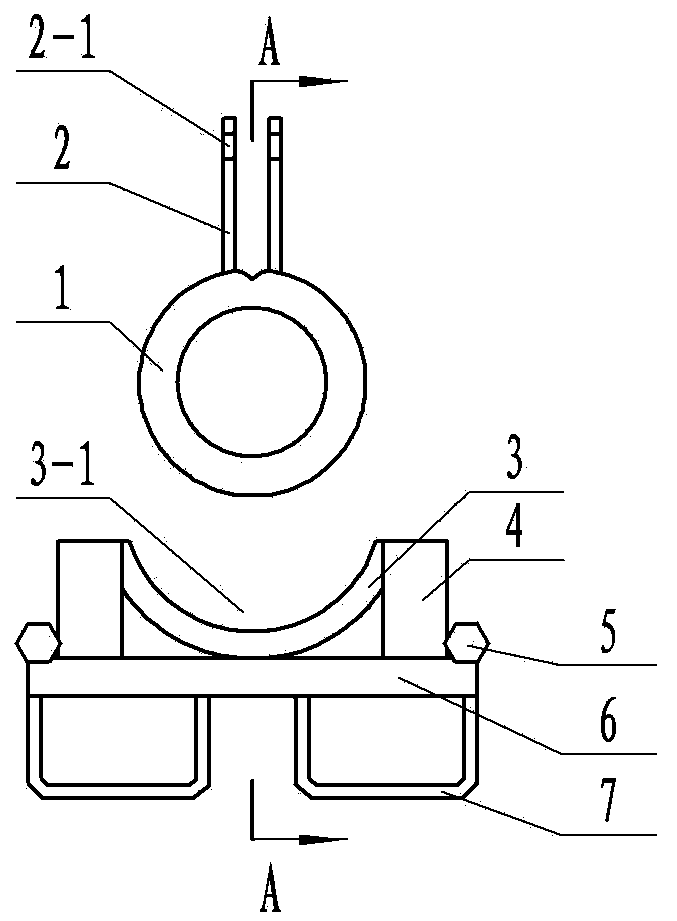

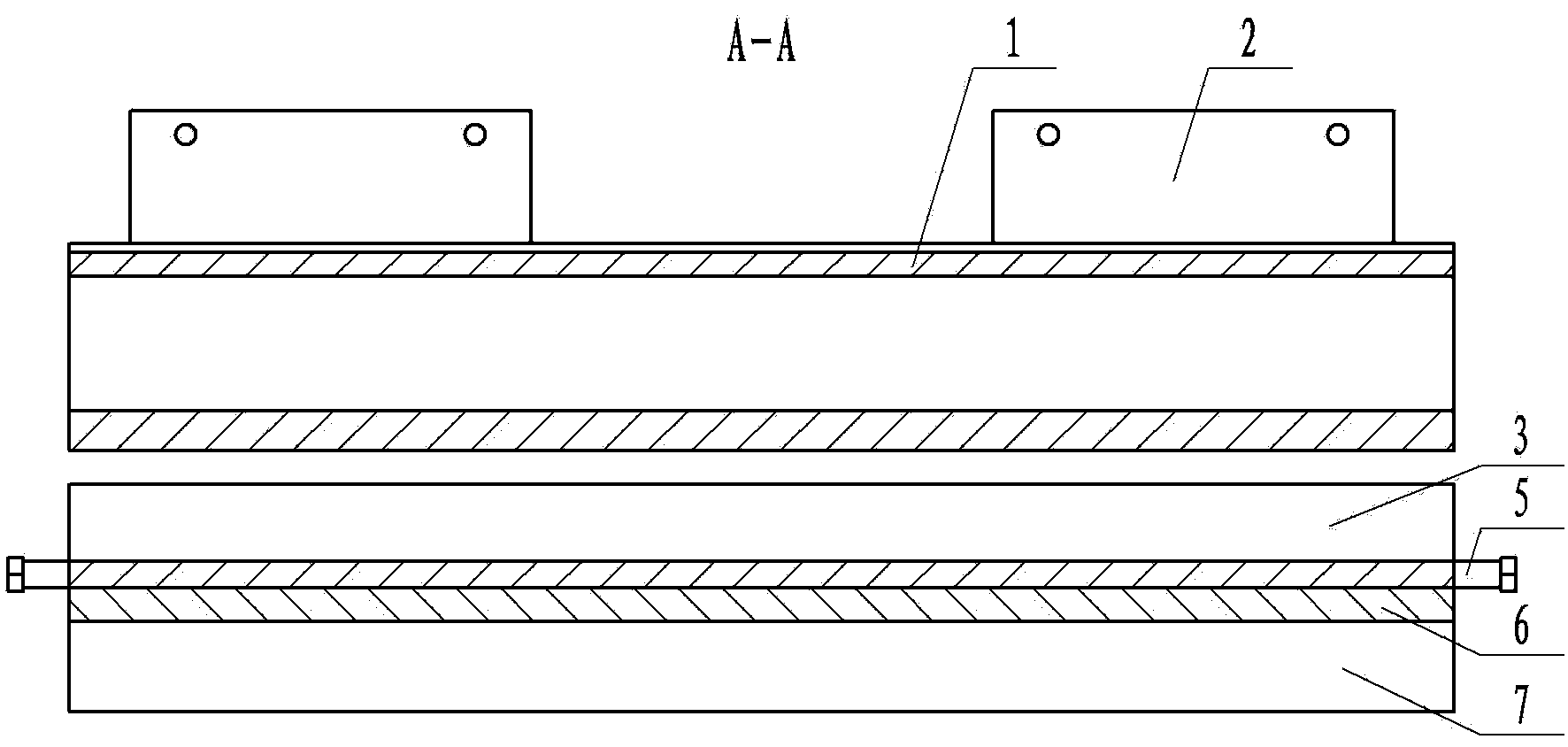

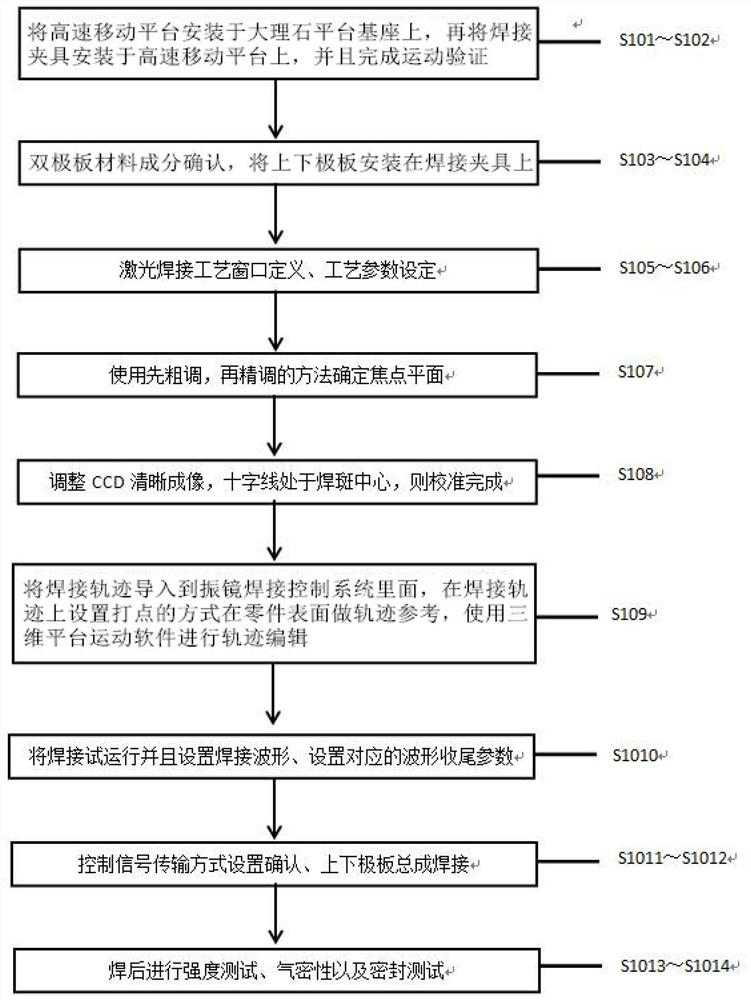

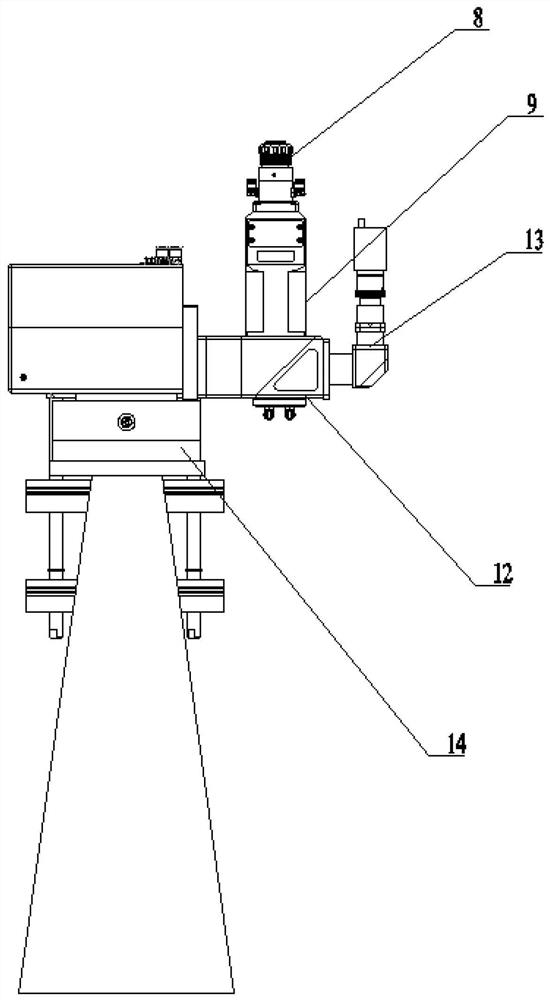

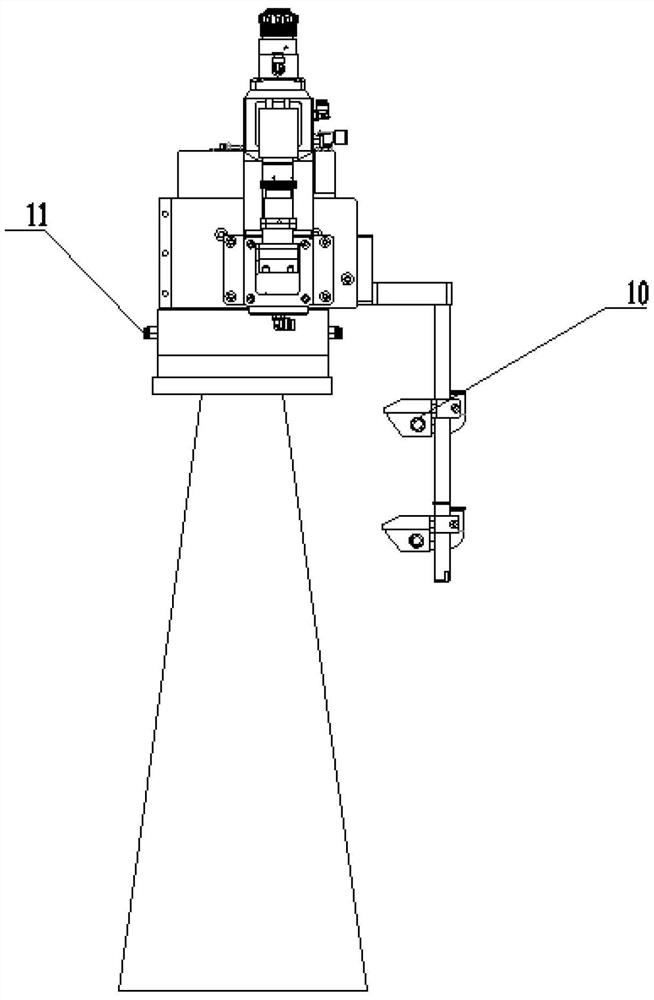

Hydrogen energy automobile bipolar plate ultrahigh-speed precision welding process and welding clamp thereof

ActiveCN113020794AIncrease profitIncreased solder contact areaLaser beam welding apparatusUltra high speedHydrogen fuel cell

The invention discloses a hydrogen energy automobile bipolar plate ultrahigh-speed precision welding process and a welding clamp thereof, and belongs to the field of hydrogen energy automobile production. A bipolar plate to be welded is included and installed on the welding clamp, the bipolar plate is moved to the mechanical welding position through a high-speed moving platform, characteristic information preset on the bipolar plate is grabbed after photographing and compared with characteristics in a photographing template, a laser beam passes through an axial lens of a galvanometer, a second shaft of the galvanometer drives the laser beam to move to the welding track end point from the welding track starting point, a complete welding line is finally formed along with movement of the galvanometer, an upper single-pole plate and a lower single-pole plate are welded together, and welding of the bipolar plate is achieved. When the process is used for welding the bipolar plate, the welding process and the welding line width are extremely stable, obvious fluctuation is avoided, the pseudo soldering problem is not likely to happen, the welding strength is high, the welding line is flat, the overcurrent capacity of the welding line is guaranteed, and the product performance of a hydrogen fuel cell is greatly improved.

Owner:龙俊耀

Sealed battery

ActiveUS10128476B2Improve securityReduce welding strengthSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsInternal pressureEngineering

A sealed battery with a battery element housed in a sealed casing. The sealed battery includes a valve brought into a closed state when a pressure of a gas in the casing is less than a first pressure P1, into an open state when the pressure is more than or equal to the first pressure P1 and less than a second pressure P2, and into the closed state when the pressure is more than or equal to the second pressure P2, and a safety mechanism configured to, when the internal pressure reaches a third pressure P3 exceeding the second pressure P2, operate in accordance with the third pressure P3.

Owner:TOYOTA JIDOSHA KK

Method for welding magnesium oxide target to back plate

InactiveCN112355427AIncrease binding areaImprove welding strengthWelding/soldering/cutting articlesSoldering auxillary devicesMetallurgySand blasting

The invention provides a method for welding a magnesium oxide target to a back plate, and relates to the field of sputtering targets. The method comprises the steps of performing cleaning and sand blasting treatment on a target welding face and a back plate welding face; and pouring molten brazing filler metal onto the target welding face and the back plate welding face obtained after sand blasting treatment, and further enabling the brazing filler metal to infiltrate the target welding face and the back plate welding face by using ultrasonic waves to realize welding. According to the method,the welding bonding strength of the brazing filler metal and the welding faces is improved by adding the sand blasting treatment process on the welding faces, the welding quality is enhanced, the method is easy and convenient to operate, and the welding rate can reach 99% or above.

Owner:河南东微电子材料有限公司

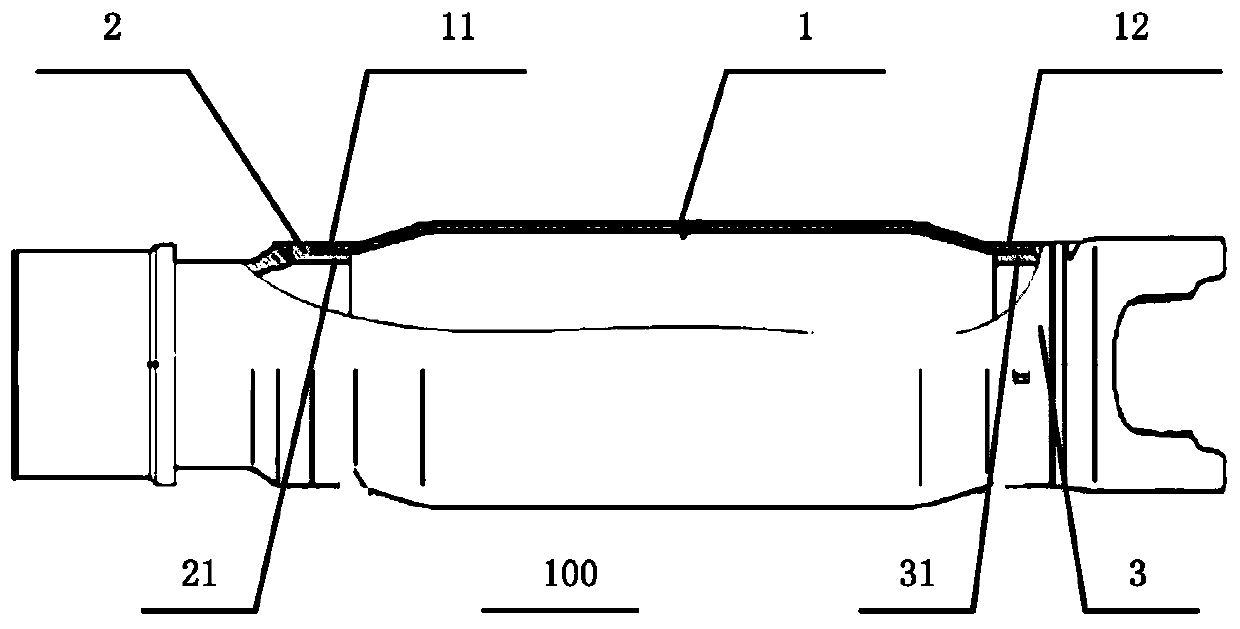

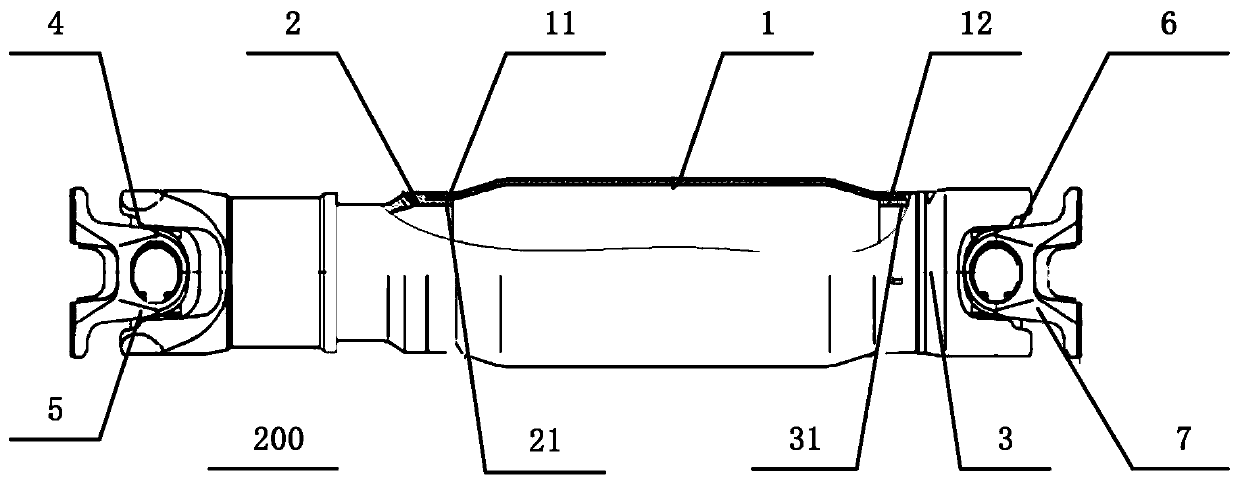

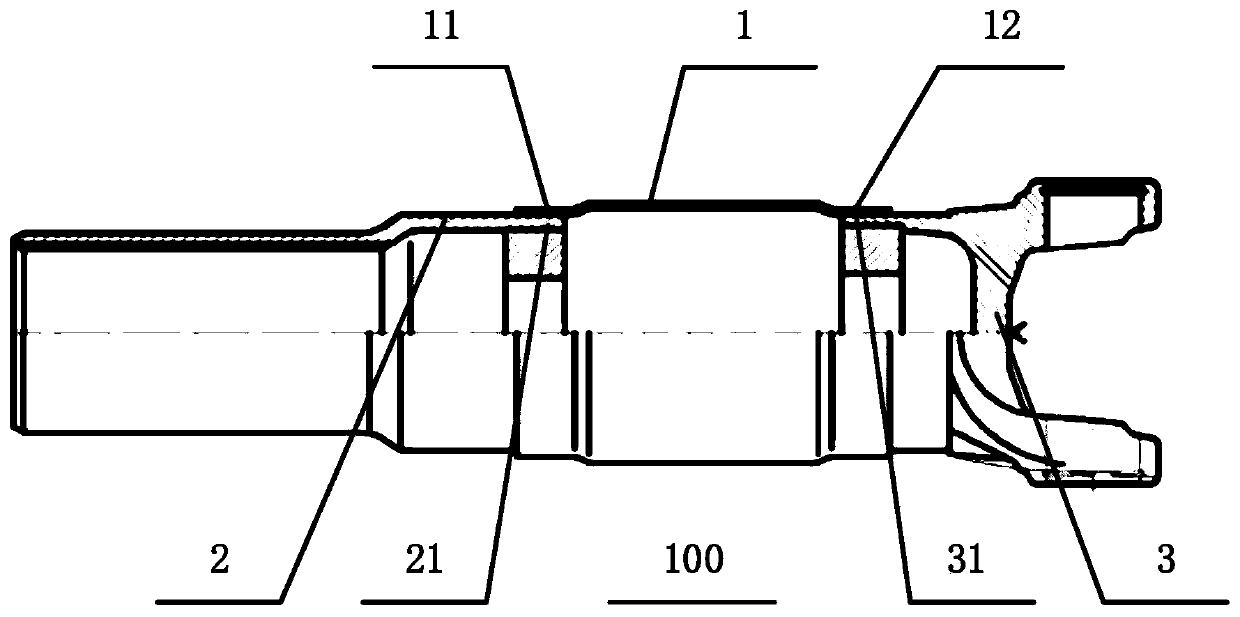

Transmission shaft, transmission shaft assembly and transmission shaft welding method

PendingCN111140601AGood stabilityNo loss of welding strengthYielding couplingNon-electric welding apparatusAssembly lineWeld strength

The invention discloses a transmission shaft. The transmission shaft comprises a shaft tube, a spline sleeve and a universal joint fork, wherein the shaft tube is provided with a first end part and asecond end part; the spline sleeve is inserted into the interior of the first end part of the shaft tube, the inner wall of the first end part of the shaft tube is connected with the outer wall of thespline sleeve through magnetic pulse welding, and the axis of the spline sleeve is coaxial with the axis of the shaft tube; and the universal joint fork is inserted into the interior of the second end part of the shaft tube, the inner wall of the second end part of the shaft tube is connected with the outer wall of the universal joint fork through magnetic pulse welding, and the axis of the universal joint fork is coaxial with the axis of the shaft tube. According to the embodiment, the shaft tube is connected with the spline sleeve and the universal joint fork through magnetic pulse welding,the welding quality stability is good, the welding strength is not lost, namely, the weld joint strength is improved; and the shaft tube is made of an aluminum alloy material, so that the mass of thetransmission shaft is reduced; and the transmission shaft is low in cost and suitable for assembly lines and professional production lines for mass production.

Owner:东风汽车底盘系统有限公司

Brazing copper alloy with high strength and corrosion resistance

InactiveCN102310298AImprove brazing strengthStrong corrosion resistanceWelding/cutting media/materialsSoldering mediaCorrosion resistantHigh intensity

The invention discloses a brazing copper alloy with high strength and corrosion resistance. The brazing copper alloy comprises the following ingredients in percentage by mass: 2.8-4.0% of Si, 0.5-1.5% of Mn, 0.2-1.0% of Mg, 0.1-0.8% of Ti, 0.01-0.1% of Ce and the rest amount of Cu. The brazing copper alloy disclosed by the invention has the advantages of high brazing strength, excellent corrosion resistance and good machining performance. As a small amount of Ti, Ce and Mg is added in the Cu-Si alloy, the brazing alloy provided by the invention has an obviously-fined grain size for casting line blanks, and the grain size is about one third of that of the S211 alloy; and the machining hardening ratio is obviously lowered, and the processing capability is enhanced.

Owner:TIANJIN JINLONG WELDING MATERIAL

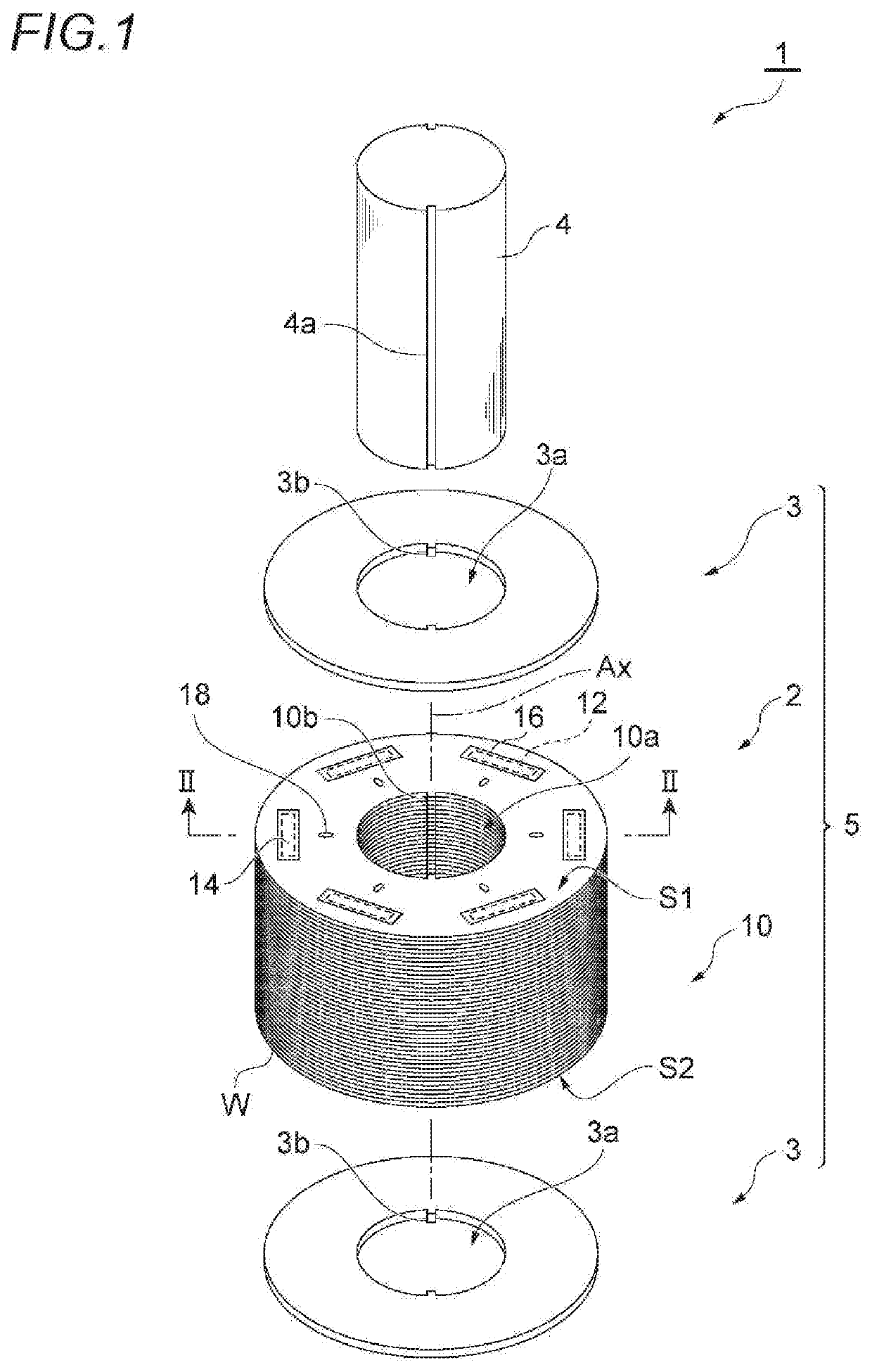

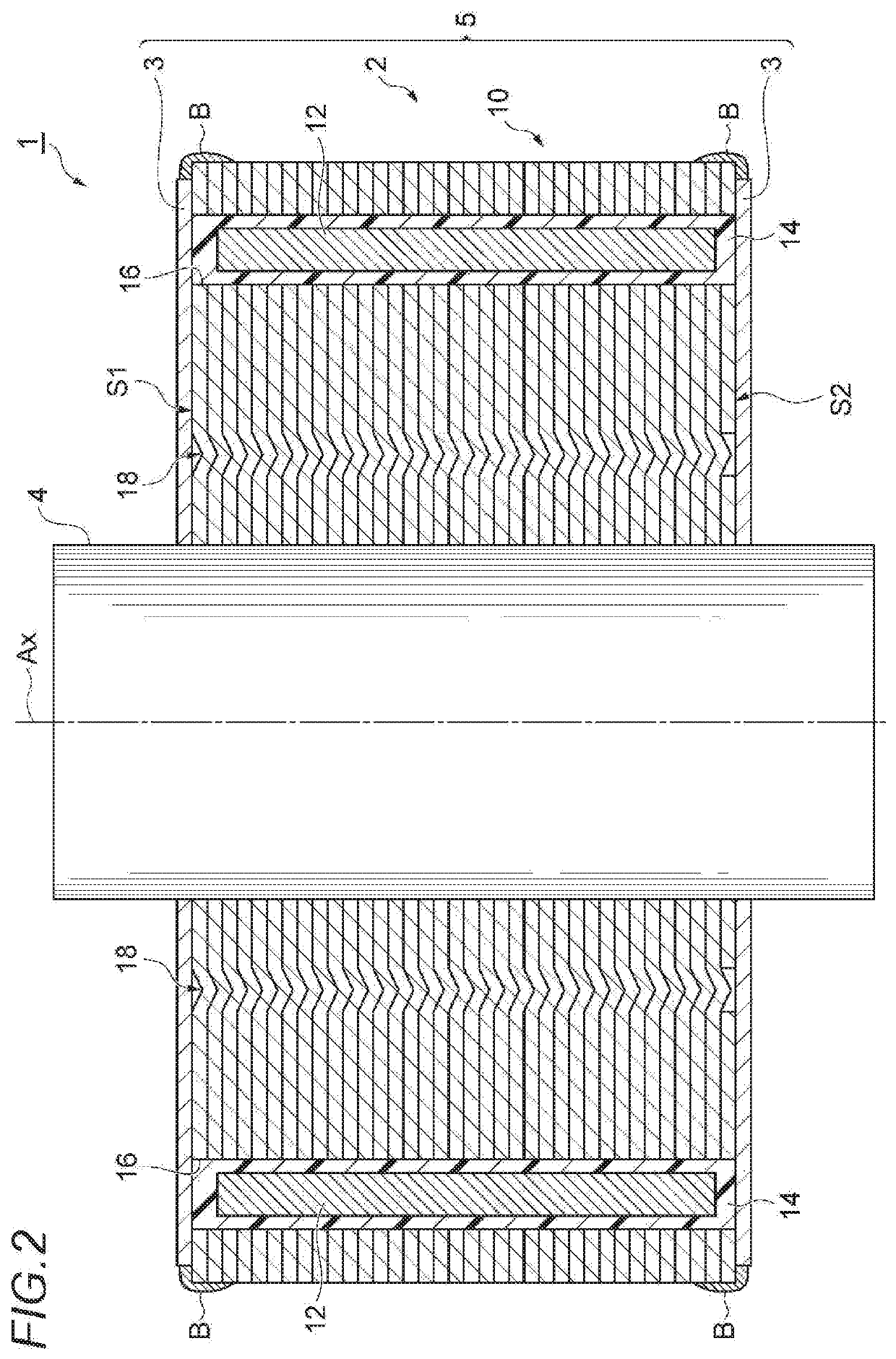

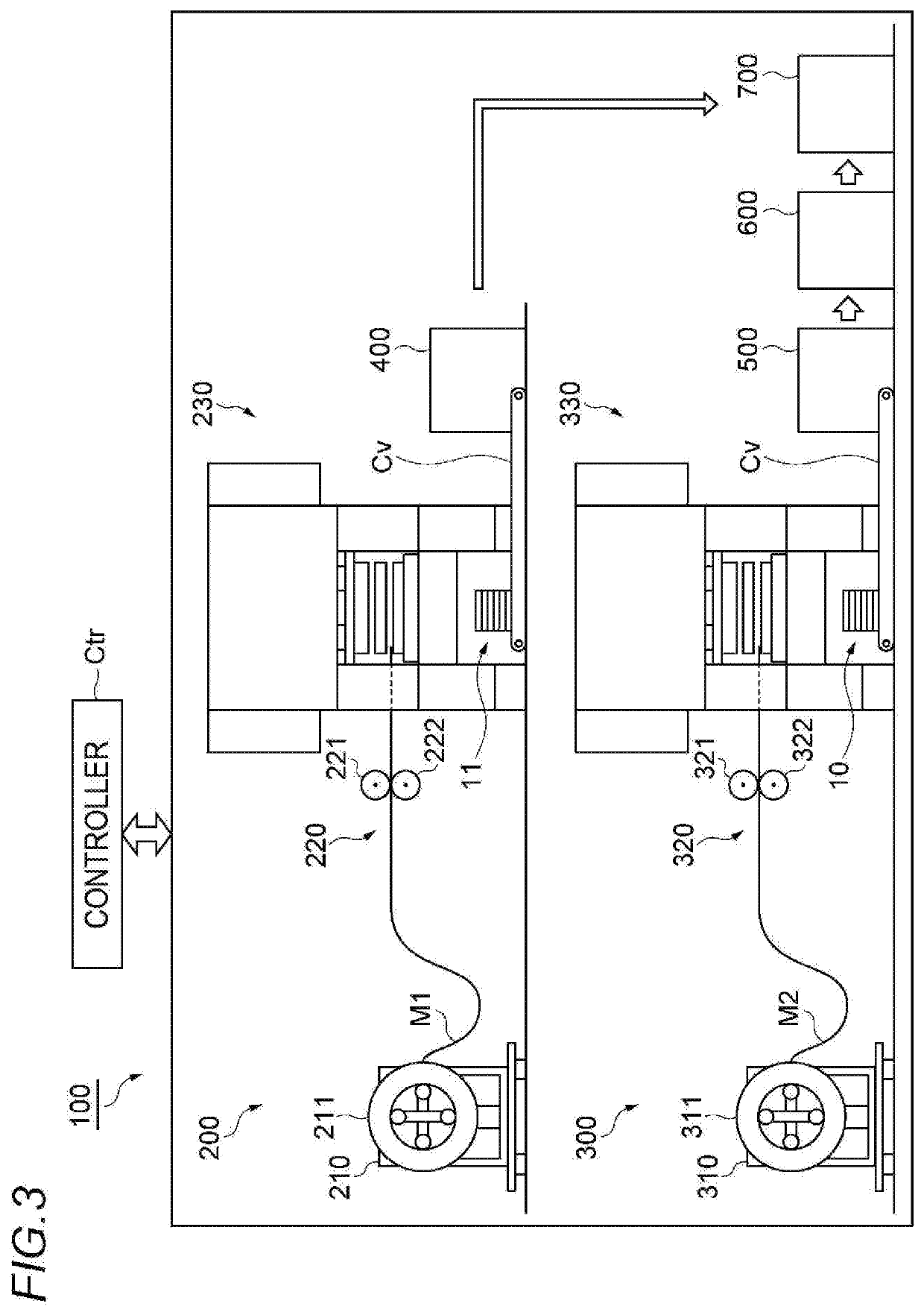

Method and apparatus for manufacturing laminated iron core product

ActiveUS20200177064A1Inhibit wearImprove stamping effectMagnetic circuit rotating partsLaminationMechanical engineeringComposite material

A method for manufacturing a laminated iron core product includes laminating a plurality of iron core members which are punched from a first metal plate to form a laminate, removing oil adhering to the laminate, removing oil adhering to an end surface plate which is punched from a second metal plate, and disposing the end surface plate on an end surface of the laminate and welding the end surface plate and the laminate.

Owner:MITSUI HIGH TEC INC

Superconductive wire rod and preparation method thereof

ActiveCN104851513AImprove performanceAchieve weldingSuperconductors/hyperconductorsSuperconductor devicesWire rodOxidation resistant

Provided in the invention is a superconductive wire rod comprising a substrate, an interlayer formed on the substrate, a superconductive layer formed on the interlayer, a Ag layer formed on the superconductive layer, a Cu layer formed on the Ag layer, and an anti-oxidation layer formed on the Cu layer. The anti-oxidation layer is in a liquid or solid state under a normal temperature and is converted into a gaseous state under a welding temperature. In addition, the invention also provides a preparation method of the superconductive wire rod. Under a normal temperature, the Cu of the wire rod is protected by the anti-oxidation layer; and the Cu layer is not oxidized and no copper oxide is generated during the long-time transport and storage process. When the superconductive wire rod and an electrode is welded, the anti-oxidation layer on the Cu layer is converted into one in a gaseous state under a welding temperature and thus the Cu layer is exposed, thereby realizing welding of the Cu and the electrode. Therefore, the welding intensity is not reduced; the welding part resistance is not increased; and the degradation of the superconductive wire rod is not influenced.

Owner:富通集团(天津)超导技术应用有限公司 +2

Brazing titanium-copper alloy with high strength and corrosion resistance

InactiveCN102310296AImprove brazing strengthImprove corrosion resistanceWelding/cutting media/materialsSoldering mediaAdditive ingredientTitanium

The invention discloses a brazing titanium-copper alloy with high strength and corrosion resistance. The brazing titanium-copper alloy comprises the following ingredients in percentage by mass: 2.8-3.5% of Si, 1.0-1.2% of Mn, 0.2-0.4% of Ti, 0.05-0.08% of Ce and the rest amount of Cu. The brazing titanium-copper alloy disclosed by the invention has the advantages of high brazing strength, excellent corrosion resistance and good machining performance. As a small amount of Ti and Ce is added in the Cu-Si alloy, the brazing alloy provided by the invention has an obviously-fined grain size for casting line blanks, and the grain size is about one third of that of the S211 alloy.

Owner:TIANJIN JINLONG WELDING MATERIAL

Spark plug

ActiveUS8922103B2Increased durabilityIncrease resistanceSparking plugsWelding/cutting media/materialsNormal zoneHeat-affected zone

A spark plug (1) includes a metallic shell (3) and a ground electrode (27) resistance-welded to the metallic shell (3). The ground electrode (27) is formed from a metal material in which precipitates PR containing at least one of an oxide, an intermetallic compound, etc., are precipitated in grain boundaries. The diameter of an equivalent circle of a precipitate PR having the greatest area is 50 μm or less, and the shortest distance between the precipitates PR is 2 μm or greater. The area occupied by the precipitates PR on the section of the heat-affected zone 27A is equal to 65% or more the area occupied by the precipitates PR (the diameter of an equivalent circle of a precipitate PR having the greatest area) on a section of the normal zone 27B.

Owner:NGK SPARK PLUG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com