Machining technology of non-fin heat exchanger

A processing technology and heat exchanger technology, applied in heat exchange equipment, metal processing, metal processing equipment, etc., can solve problems such as low strength of welds, easy stress at joints, deformation of flat tubes, etc., to improve wettability , Improve the firmness, the effect of the weld is firm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

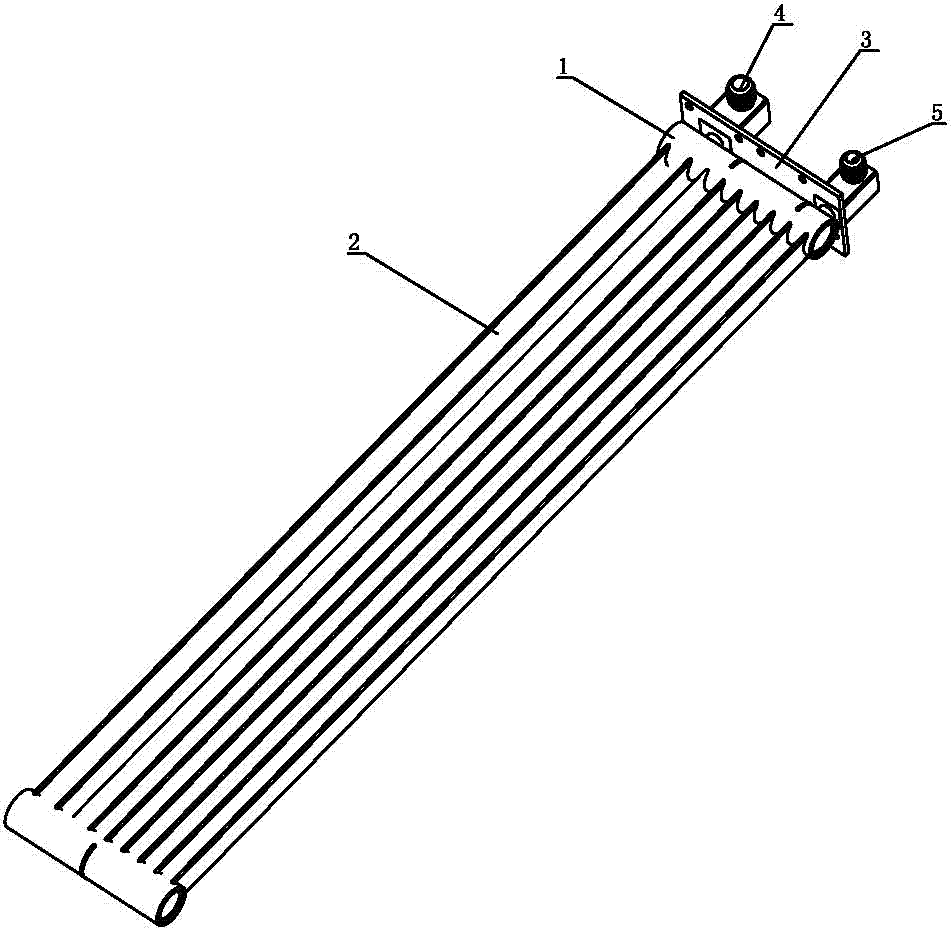

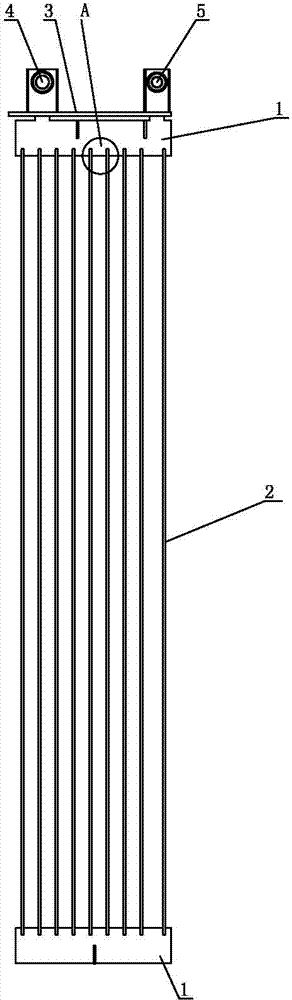

[0027] The processing technology of the finless heat exchanger includes the following steps:

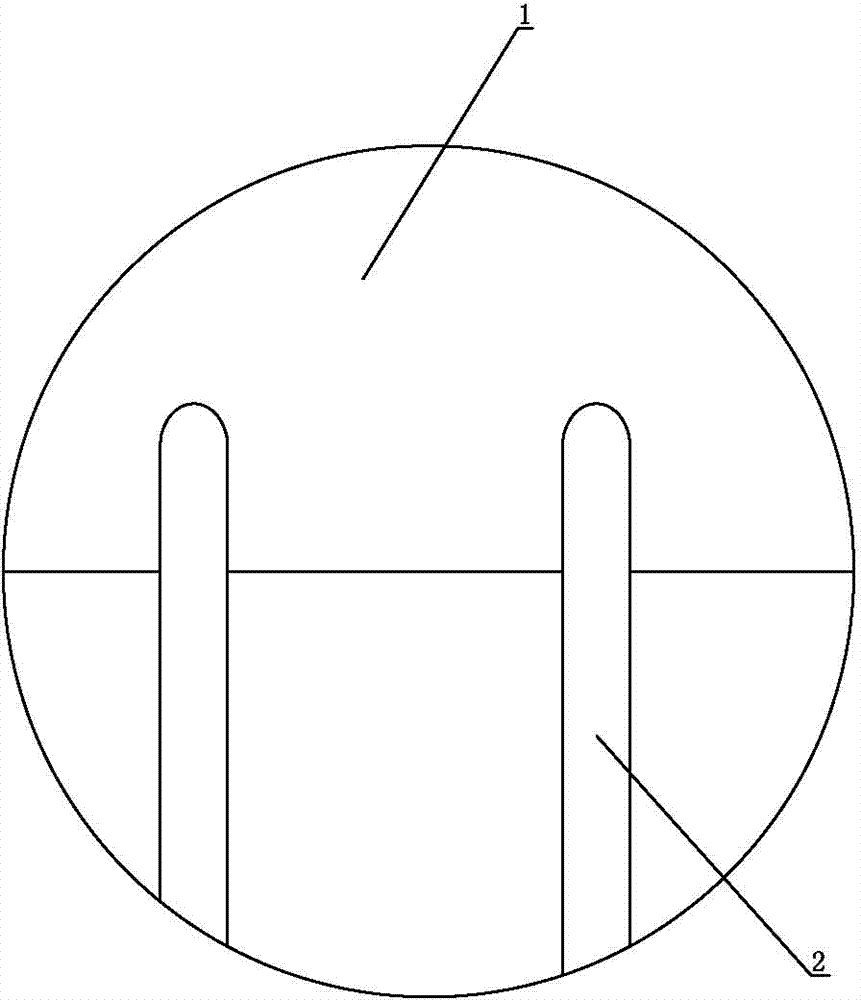

[0028] (1) On the circumference of the tube body 1, process sockets for inserting flat tubes, and the distance between adjacent sockets is 2mm;

[0029] (2) Insert the two ends of the flat tube 2 into the corresponding jacks on the tube body at both ends;

[0030] (3) Set welding positioning tool between the flat tubes; and clamp the flat tubes into the slot 7. In a group of flat tubes composed of multiple flat tubes, set different numbers of welding positions according to the length of the flat tubes. positioning tooling;

[0031] (4) Apply solder paste to the connection between the tube body and the flat tube on the tube body 1 and the flat tube 2;

[0032] (5) On both sides of the flat tube 2, strengthen the welding rods that are attached to the circumferential wall of the pipe body; On flat tube 2, adopt U-shaped reinforcing electrode, be convenient to place, locate reinforcin...

no. 2 approach

[0036] The processing technology of the finless heat exchanger includes the following steps:

[0037] (1) Process sockets for flat tube insertion on the circumference of the tube body 1, and the distance between adjacent sockets is 3mm;

[0038] (2) Insert the two ends of the flat tube 2 into the corresponding jacks on the tube body at both ends;

[0039] (3) Set welding positioning tool between the flat tubes; and clamp the flat tubes into the slot 7. In a group of flat tubes composed of multiple flat tubes, set different numbers of welding positions according to the length of the flat tubes. positioning tooling;

[0040] (4) Apply solder paste to the connection between the tube body and the flat tube on the tube body 1 and the flat tube 2;

[0041] (5) On both sides of the flat tube 2, strengthen the welding rods that are attached to the circumferential wall of the pipe body; On flat tube 2, adopt U-shaped reinforcing electrode, be convenient to place, locate reinforcing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com