Method for measuring steady-state thermal resistance value of IGBT

A thermal resistance and steady-state technology, applied in the IGBT field, can solve problems such as uneven junction temperature distribution, and achieve the effect of saving test time and uniform chip temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

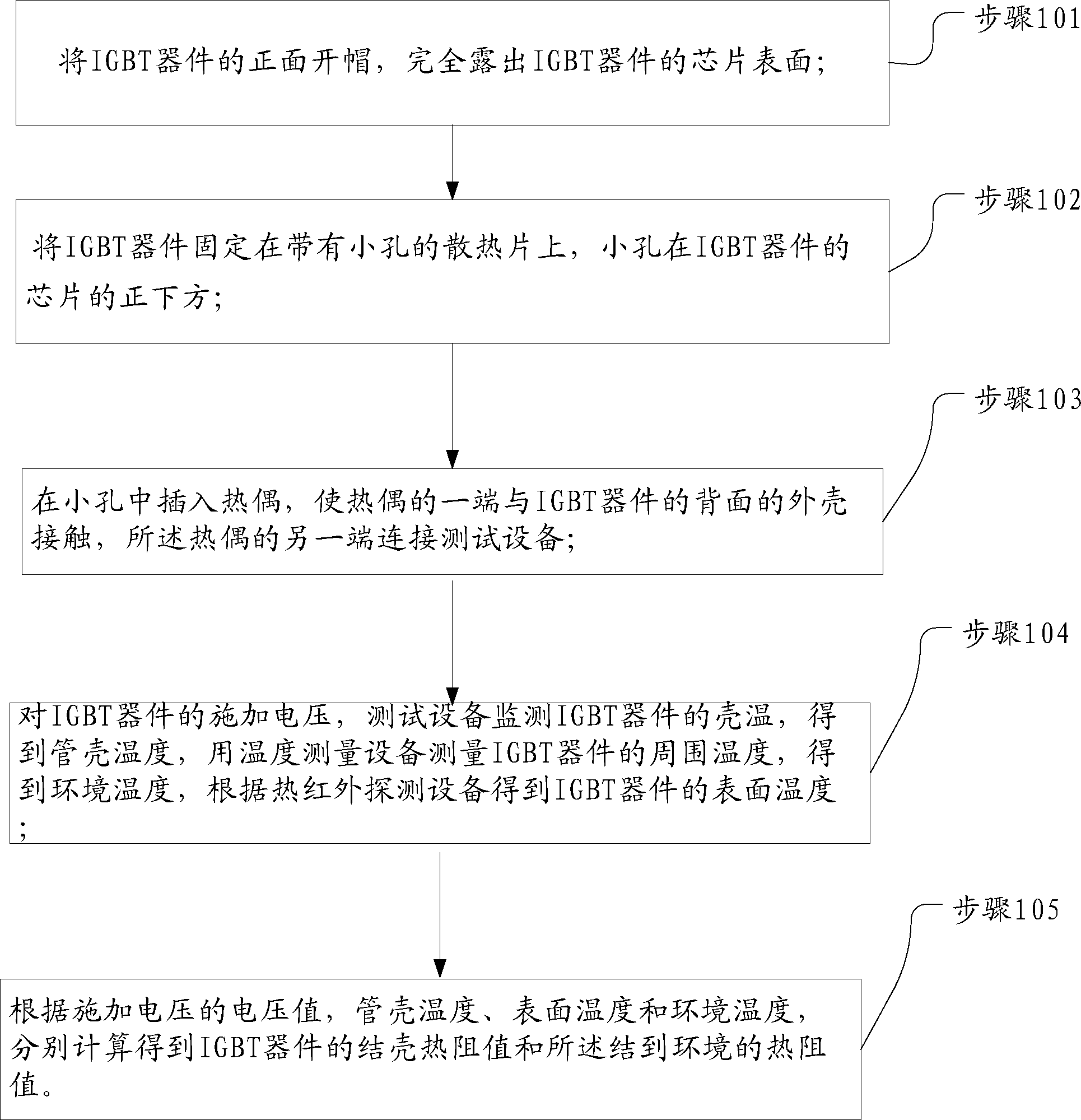

[0023] see figure 1 , a method for measuring the steady-state thermal resistance of an IGBT provided by an embodiment of the present invention includes the following steps:

[0024] Step 101: Uncap the front side of the IGBT device to completely expose the chip surface of the IGBT device;

[0025] Step 102: Fix the IGBT device on a heat sink with a small hole directly below the chip of the IGBT device;

[0026] Step 103: inserting a thermocouple into the small hole, making one end of the thermocouple contact the shell on the back of the IGBT device, and the other end of the thermocouple is connected to the test equipment;

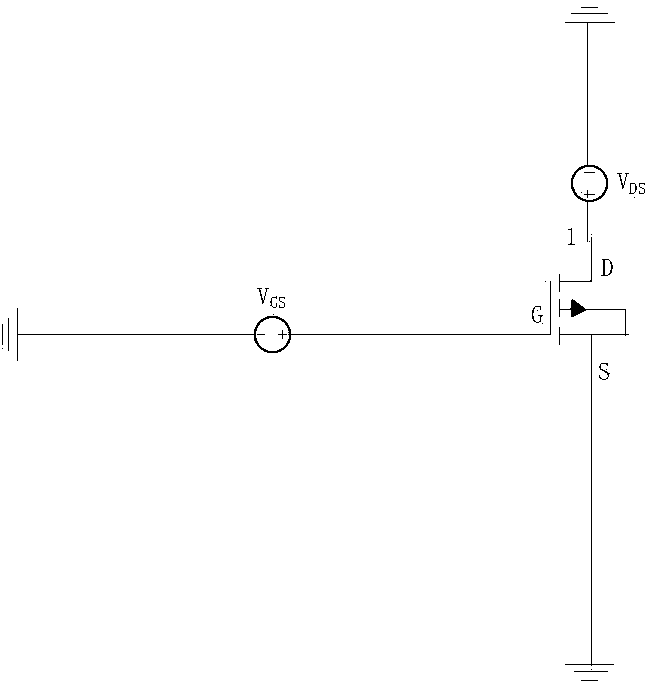

[0027] Step 104: Applying voltage to the IGBT device, the test equipment monitors the case temperature of the IGBT device to obtain the case temperature, measures the ambient temperature of the IGBT device with a temperature measuring device, obtains the ambient temperature, and obtains the surface temperature of the IGBT device according to the thermal in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com