A lightweight design method for crane metal structures

A lightweight design, metal structure technology, applied in computing, special data processing applications, instruments, etc., can solve problems such as low optimization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further elaborated below with reference to the accompanying drawings and specific implementation cases completed according to the technical solutions of the present invention.

[0046] Taking the traditional gantry crane as the research object, the specific implementation steps of using the improved fruit fly algorithm to carry out the lightweight design of the metal structure are as follows:

[0047] 1) Determine design variables

[0048] The variables for this optimization are expressed by the following formula (1),

[0049]

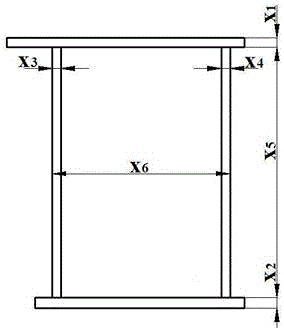

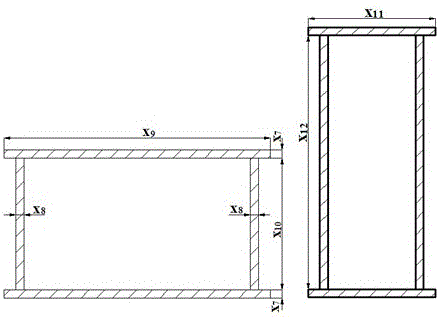

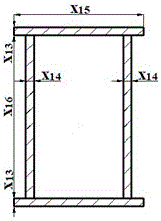

[0050] The meaning of each parameter in the formula is as follows figure 1 , 2 and 3 are shown, specifically,

[0051] x 1 - Thickness of upper flange plate of main girder;

[0052] x 2 - Thickness of lower flange plate of main girder;

[0053] x 3 - Thickness of main girder main web;

[0054] x4 - Thickness of main girder auxiliary web;

[0055] x 5 -Inner spacing of main girder flange plate;

[0056...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com