Single-ended power supply all-around LED lamp filament and manufacturing method thereof

A LED filament, single-ended power supply technology, applied in the direction of circuits, electrical components, electrical solid devices, etc., can solve the problems of insufficient reflection, fragile LED chip connection, inconvenient electrode connection, etc., to avoid insufficient reflection, coating process Improved, good luminous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

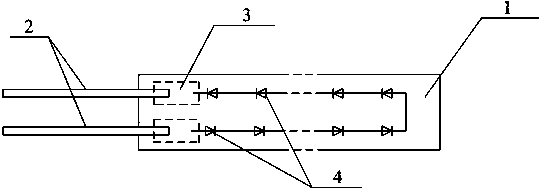

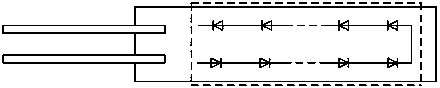

[0028] The specific embodiment of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0029] Such as figure 1 As shown, the present invention selects a strip substrate as the main body of the filament carrying the LED chip. The strip substrate is usually rectangular, and can also be chamfered at the corners of the rectangle. The length and width of the rectangle are similar to the usual filament size, for example, 10 mm wide , 150 mm long, the strip substrate must choose transparent insulating materials to ensure 360-degree omnidirectional light, in order to ensure the light transmission effect, the strip substrate should choose materials with high light transmittance, such as high borosilicate glass, high borosilicate glass ( Also known as hard glass), the linear thermal expansion coefficient is (3.3±0.1)×10-6 / K, and the light transmittance is even higher than that of ultra-white glass, which can reach more than 90%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com